Method for recycling gallium, indium and germanium from wasted thin-film solar cells

A technology for solar cells and thin films, applied in the field of recycling gallium, indium, and germanium, can solve the problems of inhibiting the recycling of waste thin-film solar cells, low efficiency, complicated processes, etc., and achieve the effects of reducing recycling costs, improving recycling efficiency, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

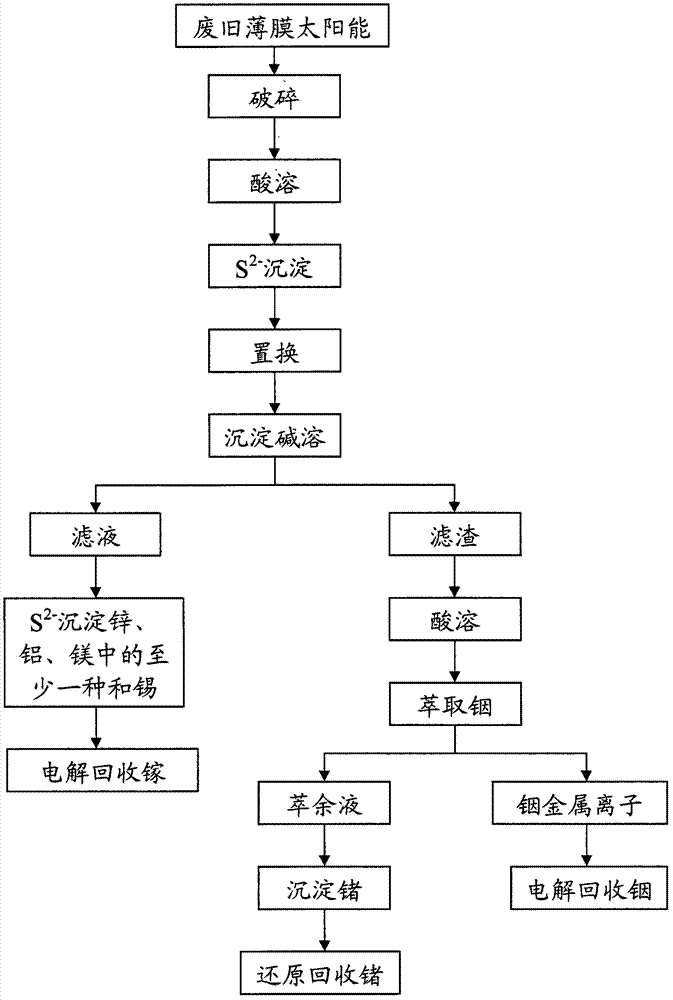

Image

Examples

Embodiment 1

[0053] A method for reclaiming gallium, indium and germanium from waste thin film solar cells, the specific steps are as follows:

[0054] Step S11. Obtain the first separation liquid containing gallium, indium, germanium, cadmium, copper, tin, zinc metal ions:

[0055] Add the pulverized waste thin-film solar cell powder with a particle size of 0.5 to 1 mm into a mixed solution of sulfuric acid and nitric acid containing an oxidizing agent, stir at a speed of 100 r / min and react at 80°C for 6 hours, then perform solid-liquid separation, and collect gallium-containing , indium, germanium, cadmium, copper, tin, the first separation liquid of zinc metal ion; Wherein, in the mixed solution of sulfuric acid and nitric acid, hydrogen ion concentration is 1mol / L, and the molar ratio of sulfuric acid and nitric acid is 1: 0.4, The solid-to-liquid ratio of the mixed solution of waste thin-film solar cell powder and sulfuric acid and nitric acid is 1g: 2ml; Oxidant is sodium chlorate, ...

Embodiment 2

[0069] A method for reclaiming gallium, indium and germanium from waste thin film solar cells, the specific steps are as follows:

[0070] Step S21. Obtain the first separation liquid containing gallium, indium, germanium, cadmium, copper, tin, zinc metal ions:

[0071] This step is referring to step S11 among the embodiment 1, difference is: the rotating speed of stirring is 60r / min, and the temperature of reaction is 60 ℃, and the reaction time is 10 hours; The hydrogen ion concentration in the mixed solution of sulfuric acid and nitric acid is 0.7mol / L, the molar ratio of sulfuric acid and nitric acid is 1: 0.3, the solid-liquid ratio of the mixed solution of waste thin film solar cell powder and sulfuric acid and nitric acid is 1g: 1ml; Oxidant is hydrogen peroxide, and its quality is the mass of thin film solar cell powder 0.1 times;

[0072] Step S22. Obtaining the second separating liquid:

[0073] This step refers to step S12 in Example 1, the difference is: the pH ...

Embodiment 3

[0086] A method for reclaiming gallium, indium and germanium from waste thin film solar cells, the specific steps are as follows:

[0087] Step S31. Obtain the first separation liquid containing gallium, indium, germanium, cadmium, copper, tin, zinc metal ions:

[0088] This step is referring to step S11 among the embodiment 1, difference is: the rotating speed of stirring is 200r / min, and the temperature of reaction is 99 ℃, and the reaction time is 3 hours; The hydrogen ion concentration in the mixed solution of sulfuric acid and nitric acid is 0.5mol / L, the molar ratio of sulfuric acid and nitric acid is 1: 0.6, the solid-to-liquid ratio of waste thin film solar cell powder and the mixed solution of sulfuric acid and nitric acid is 1g: 3ml; Oxidant is potassium permanganate, and its quality is thin film solar cell 0.1 times the mass of the powder;

[0089] Step S32. Obtaining the second separating liquid:

[0090] Refer to step S12 in Example 1 for this step, the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com