Method for sequentially extracting tea saponin and tea seed oil from oil-tea camellia seeds

A technology of camellia oleifera seed and tea saponin, which is applied in the field of extracting tea seed oil by water substitution method, can solve the problems of high energy consumption, long process flow, hidden dangers of tea seed oil food safety enzymes, etc., achieve low energy consumption, improve decontamination ability, the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

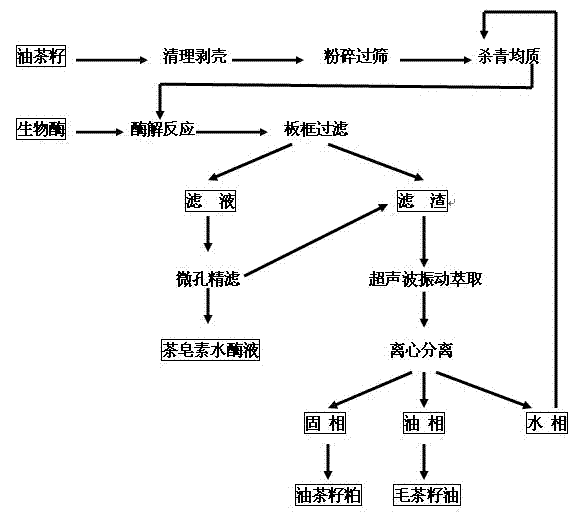

[0038] After cleaning the camellia seed, peeling off the shell, removing the seed coat, pulverizing and sieving through a sieve with an aperture of 100 mesh, to obtain the camellia seed kernel powder. The prepared Camellia oleifera seed kernel powder is added into hot water at 80°C with a water-to-material ratio of 5:1 (ml / g), and after being finished in a hot water tank, it is sent to a homogenizer for full homogenization to obtain a Camellia oleifera seed emulsion . After the camellia seed emulsion is cooled to 40°C, add 0.5% compound enzyme powder (composed of 20% pectinase, 30% amylase, 30% alkaline protease, and 20% cellulase) to adjust The pH of the enzymolysis solution is 9.0, and the enzymolysis is performed under mechanical stirring for 1.5 hours. The obtained enzymolysis product is coarsely filtered through a plate and frame filter, and the filter residue is used for later use. The coarse filtrate is finely filtered through a ceramic membrane with a microporous membr...

Embodiment 2

[0040] After cleaning the camellia seed, shelling it, removing the seed coat, pulverizing and sieving through a sieve with an aperture of 80 meshes, to obtain the camellia seed kernel powder. The prepared camellia seed kernel powder is added into hot water at 90°C with a water-to-material ratio of 4:1 (ml / g), and after being finished in a hot water tank, it is sent to a homogenizer to fully homogenize and finish, and the camellia seed emulsion is obtained. liquid. After the Camellia oleifera seed emulsion is cooled to 45°C, add 0.6% compound enzyme powder (composed of 15% pectinase, 35% amylase, 25% alkaline protease, and 25% cellulase) to adjust The pH of the enzymolysis solution is 10.0, and the enzymolysis is performed under mechanical stirring for 2 hours. The obtained enzymolysis product is coarsely filtered through a plate and frame filter, and the filter residue is used for later use. The combined filter residues are poured into an extraction cylinder equipped with an ...

Embodiment 3

[0042] After cleaning the camellia seed, peeling off the shell, removing the seed coat, pulverizing and sieving through a sieve with an aperture of 100 mesh, to obtain the camellia seed kernel powder. The prepared camellia seed kernel powder is added to hot water at 90°C with a water-to-material ratio of 6:1 (ml / g), and after it is finished in a hot water tank, it is sent to a homogenizer to fully homogenize and finish, and the camellia seed emulsion is obtained. liquid. After the camellia seed emulsion is cooled to 45°C, add compound enzyme powder (10% pectinase, 20% amylase, 20% alkaline protease, 30% glucanase, fiber 20% prime enzyme), adjust the pH of the enzymolysis reaction system to 10.0, and perform enzymolysis under mechanical stirring for 2 hours. The obtained enzymolysis product is coarsely filtered through a plate and frame filter, and the filter residue is used for later use. The crude filtrate is passed through a microporous membrane. Ceramic membrane fine filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com