Lithium-ion battery carbon-sulfur composite cathode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of battery negative electrode corrosion, damage to electrode integrity, low sulfur ion conductivity and electronic conductivity, etc., and achieve simple preparation process Efficient, easy to implement on a large scale, cheap and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

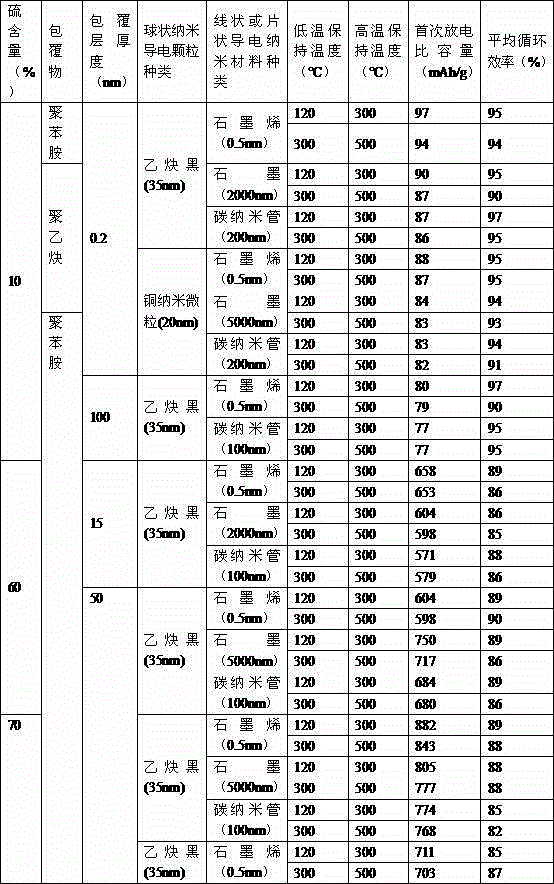

[0028] One aspect of the present invention aims to provide a carbon-sulfur composite positive electrode material for a lithium-ion battery, which has a core-shell structure, wherein the outer shell layer includes a conductive polymer layer, and the inner core layer includes a sulfur layer and evenly distributed in the sulfur layer. Nano-conductive material, said nano-conductive material includes more than one point-shaped nano-conductive particle and more than one line-shaped and / or sheet-shaped conductive nano-material.

[0029] Wherein, the size of the positive electrode material is in the range of 10 nm to 50 μm.

[0030] The aforementioned conductive polymer may include polyacetylene, polyparastyrene, polypyrrole (X=NH), polythiophene (X=S), polyaniline (X=NH / N), polyphenylene sulfide (X=S), Polymer conductors capable of electron conduction such as PDOT, but not limited thereto.

[0031] Preferably, the aforementioned conductive polymer layer has a thickness ranging from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com