Reflective body and a light-emitting device equipped with the same

一种反射体、液晶聚酯的技术,应用在半导体器件、电气元件、电路等方向,能够解决画面明暗或彩度不稳定、成型品表面产生裂纹、不能形成成型品等问题,达到减少初期反射率降低现象、防止变色、发光功能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1-1

[0057] Production Example 1-1: Production of Whole Aromatic Liquid Crystal Polyester Resin (1)

[0058] In a batch reactor with a capacity of 10 liters capable of adjusting the temperature, 3.018 kg of p-hydroxybenzoic acid, 1.300 kg of 6-hydroxy-2-naphthoic acid and 0.3 g of potassium acetate (catalyst) were injected and nitrogen gas was injected to make the inside of the above-mentioned reactor After the space became inactive, 3.024 kg of acetic anhydride (acetic anhydride) was further added to the reactor. Thereafter, the temperature of the reactor was raised to 150° C. over 30 minutes, and the hydroxyl group of the above monomer was acetylated at the above temperature for 2 hours. Then, while removing the acetic acid produced in the above-mentioned acetylation reaction, the temperature of the reactor was raised to 320°C over 5 hours and 20 minutes and then maintained for 20 minutes to produce a wholly aromatic liquid crystal polyester prepolymer by polycondensation react...

manufacture example 1-2

[0060] Production Example 1-2: Production of Whole Aromatic Liquid Crystal Polyester Resin (2)

[0061] 6.214 kg of p-hydroxybenzoic acid, 1.422 kg of terephthalic acid, and 1.121 kg of isophthalic acid were charged into a batch reactor with a capacity of 10 liters and the temperature could be adjusted, and nitrogen gas was injected to make the internal space of the reactor inactive. State, then add acetic anhydride 3.190kg again to above-mentioned reactor. After that, the temperature of the reactor was raised to 150° C. over 30 minutes and the hydroxyl groups of the above monomers were acetylated at the above temperature for 3 hours. Then, while removing the acetic acid produced in the above-mentioned acetylation reaction, the temperature of the reactor was raised to 330° C. over 6 hours to produce a wholly aromatic liquid crystal polyester prepolymer (2) by polycondensation reaction of monomers. In addition, acetic acid is regenerated as a by-product during the production...

manufacture example 2-1

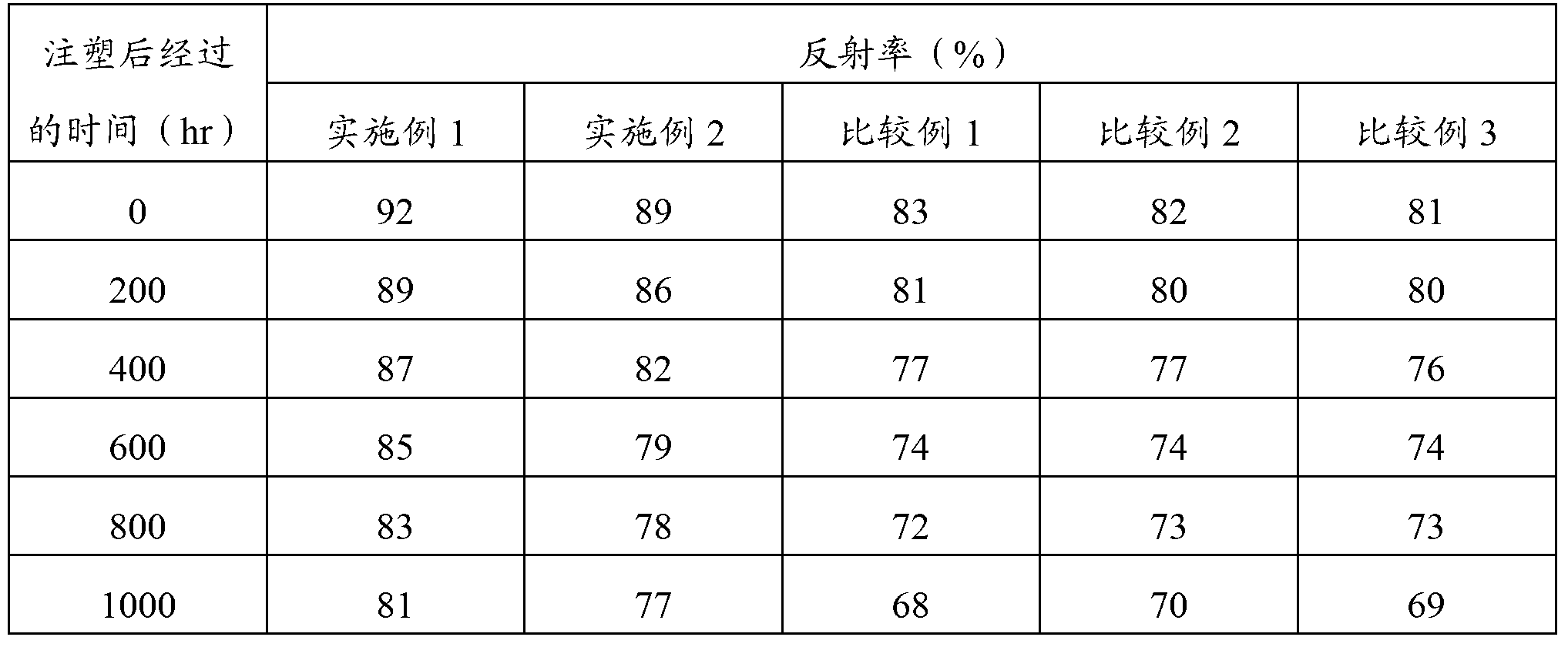

[0063] Production Example 2-1: Production of Whole Aromatic Liquid Crystal Polyester Resin Compound (1)

[0064] The wholly aromatic liquid crystal polyester resin produced in the above-mentioned production example 1-1, glass fibers with a length distribution of 100-300 μm, an average length of 150 μm, and a diameter of 10±1 μm (SEONGJIN FIBER, Korea, MF150W-AC), and Titanium oxide (Dupont, T-Pure R-105) coated with UV-stabilized aluminum oxide, silicon oxide, and a hydrophobic organic compound was mixed in a ratio of 5:1:4 by weight and used batchwise A mixer (product of Daiichi Industrial Machinery Co., Ltd.) was mixed for 30 minutes. After that, dry in an oven drier (ASUNG PLANT product) at 130°C for more than 4 hours to reduce the moisture content to below 200wtppm, and then use a twin-screw extruder (L / D: 40, diameter: 25mm) at 10kg per hour The wholly aromatic liquid crystal polyester resin compound (1) was produced by melt-kneading while quantitatively conveying at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com