Catalyst for preparing dimethylbenzene by converting methanol and preparation method of catalyst

A xylene catalyst and methanol conversion technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of unindustrialization, research stay in the experimental stage, etc., and achieve high selectivity and excellent synergy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

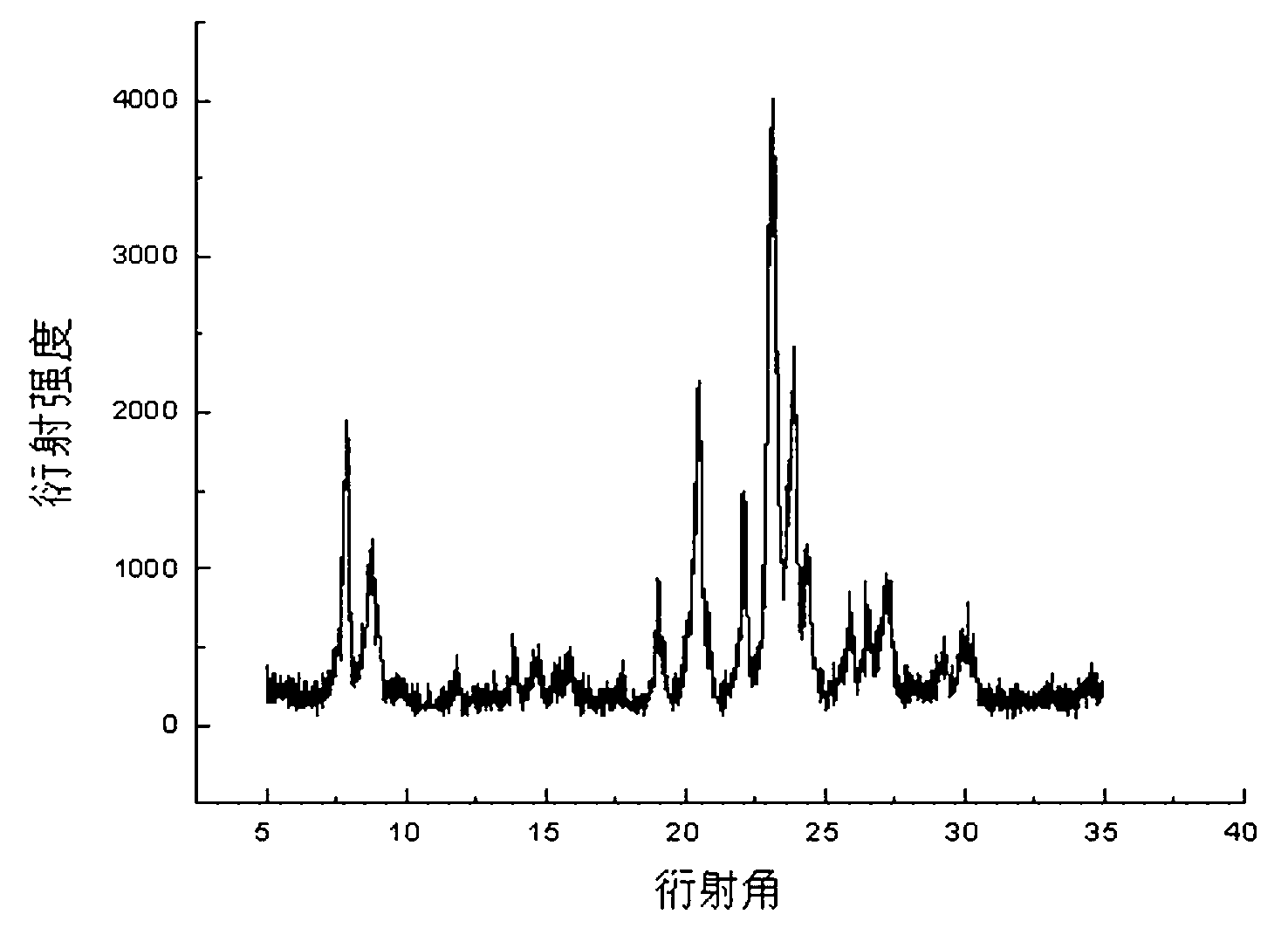

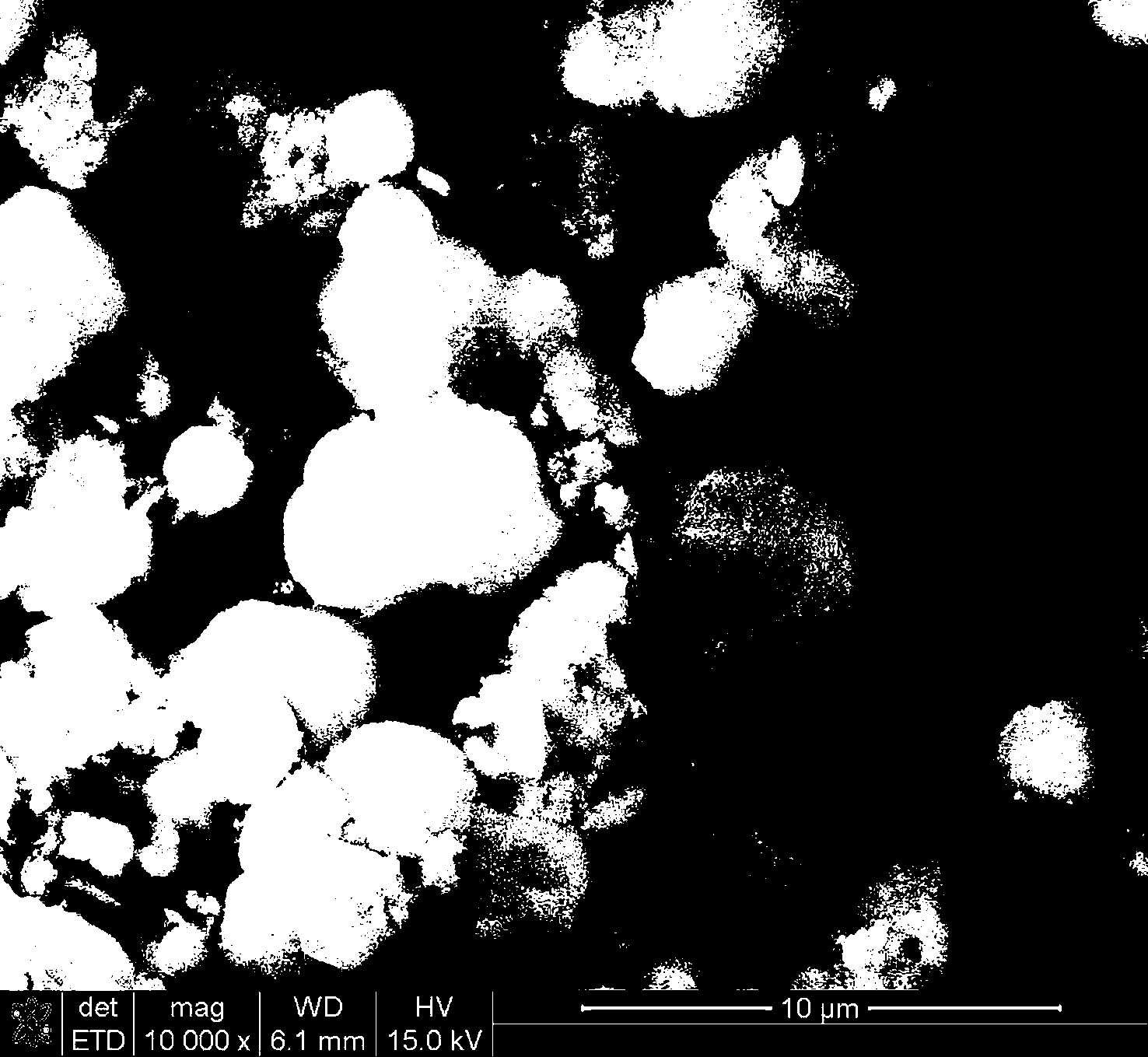

[0026] Weigh 1.5g template agent tetrapropylammonium bromide and completely dissolve it in 10ml 9.67mol / L sodium hydroxide solution, add 20ml 5.98mol / L liquid silica sol dropwise, add 1g aluminum sulfate octadecahydrate, and wait until the solution is basically clear , add 2 g of boric acid, 1 g of seed crystal EU-1 molecular sieve, stir for 60 minutes, put into the kettle, stand at 200 ° C for 2 days for crystallization, wash twice, filter, dry, and roast at 500 ° C to obtain a sodium type composite molecular sieve.

[0027] The sodium-type composite molecular sieve was ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2 hours, washed with deionized water, then ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2 hours, washed with deionized water, Filter, dry in an oven at 100°C, and place in a muffle furnace at 500°C for 4 hours to obtain a hydrogen-type composite molecular sieve.

[0028] A continuous flow fixed bed reactor (inner diameter 10...

Embodiment 2

[0031] Accurately weigh 1.1g of aluminum sulfate octadecahydrate and 0.85g of boric acid, place in 8ml of 9.67mol / L sodium hydroxide solution, add 3g of template agent tetrapropylammonium bromide, add dropwise 20ml of 5.98mol / L liquid silica sol, After the solution is evenly stirred, add 1g of EU-1 molecular sieve as a seed crystal, stir for 60 minutes, put into the kettle, stand at 200°C for crystallization for 2 days, wash with water twice, filter, dry, and roast at 500°C to obtain a sodium-type composite molecular sieve .

[0032] The sodium-type composite molecular sieve was ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2 hours, washed with deionized water, then ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2 hours, washed with deionized water, Filter, dry in an oven at 100°C, and place in a muffle furnace at 500°C for 4 hours to obtain a hydrogen-type composite molecular sieve.

[0033] A continuous flow fixed bed reactor (inner di...

Embodiment 3

[0036] Slowly drop 30ml of 4.36mol / L liquid water glass into 8ml 9.67mol / L sodium hydroxide solution, add 5g template agent tetrapropylammonium bromide, 1g aluminum sulfate octadecahydrate, stir until the solution is basically clear, then add Seed crystal EU-1 molecular sieve 1g, and then stir for 60min, finally add 1g of diboron trioxide, stir evenly, put into the kettle, stand at 170°C for crystallization for 3 days, wash with water twice, filter, dry, and roast at 500°C A sodium type composite molecular sieve is obtained.

[0037] The sodium-type composite molecular sieve was ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2 hours, washed with deionized water, then ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2 hours, washed with deionized water, Filter, dry in an oven at 100°C, and place in a muffle furnace at 500°C for 4 hours to obtain a hydrogen-type composite molecular sieve.

[0038] A continuous flow fixed bed reactor (inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com