Current collector with surface being decorated with vertical orientated grapheme and preparation method thereof

A graphene surface and vertical orientation technology, applied in the field of electrochemical energy storage, can solve the problem of low energy storage efficiency, achieve the effect of reducing contact resistance, improving rate performance and power density, and the method is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

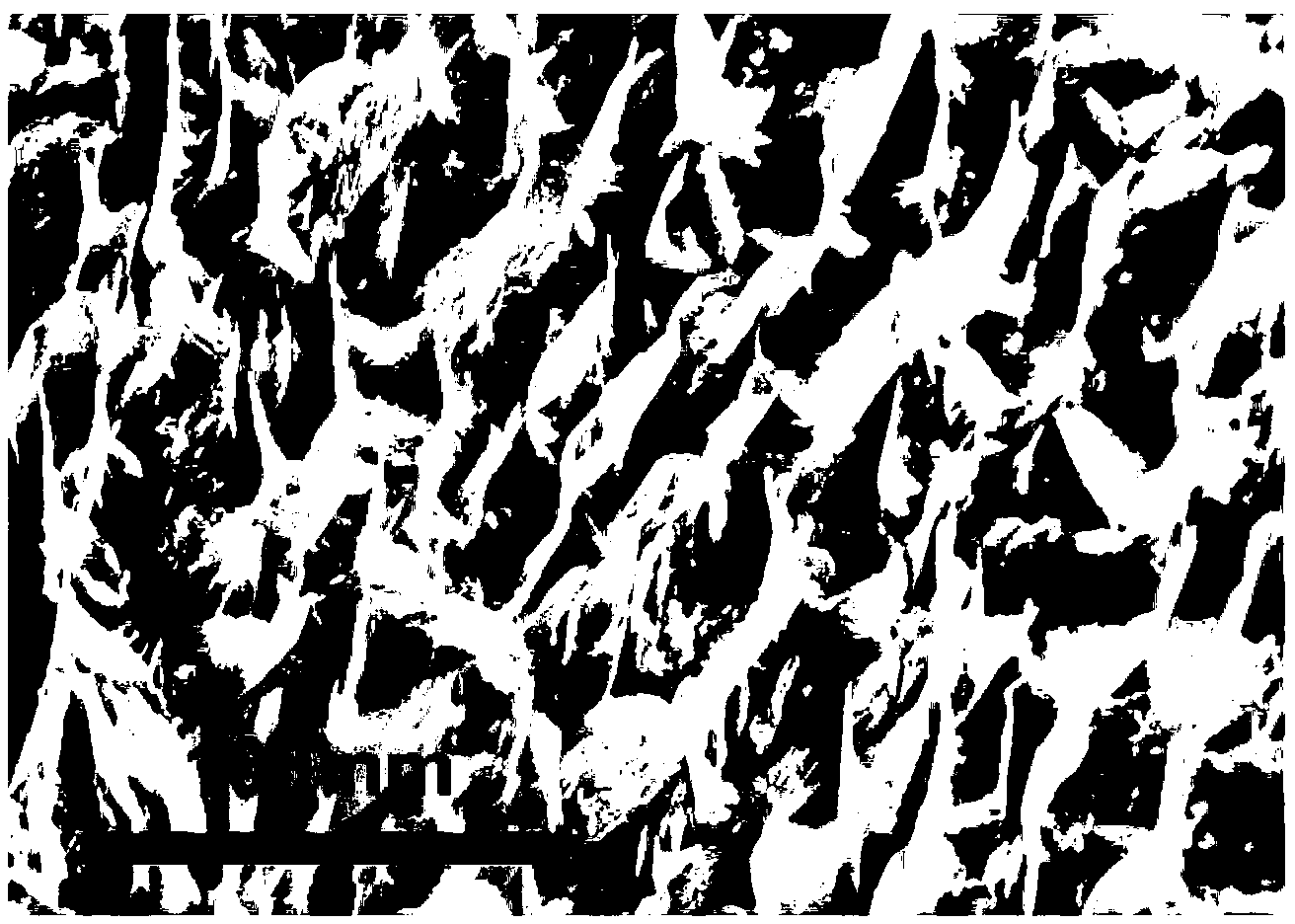

[0035] Example 1: Nickel foam current collector with vertically oriented graphene surface modification.

[0036] A pair of needle-plate electrodes are arranged in the quartz tube, the needle electrodes are connected to DC negative high voltage, and the plate electrodes are grounded. The quartz tube is placed in a temperature-controlled heating furnace, with one end ventilated and the other end open. Put the nickel foam current collector on the flat plate electrode, pass hydrogen gas into the ventilation end, and turn on the heating furnace to heat the nickel foam current collector to 700°C. After 10 minutes, the hydrogen gas was turned off and a mixed gas composed of methane, argon and water vapor was introduced, wherein the proportion of methane was 10wt%, and the relative humidity of the mixed gas was 40%. Turn on the DC negative high voltage to 10000V to form glow discharge plasma between the needle plate electrodes. After 3 minutes of discharge, turn off the DC negative ...

Embodiment 2

[0037] Example 2: Nickel sheet current collector with vertically oriented graphene surface modification.

[0038]A pair of needle-plate electrodes are arranged in the quartz tube, the needle electrodes are connected to DC negative high voltage, and the plate electrodes are grounded. The quartz tube is placed in a temperature-controlled heating furnace, with one end ventilated and the other end open. Put the nickel sheet current collector on the flat plate electrode, pass hydrogen gas into the ventilation end, and turn on the heating furnace to heat the nickel foam current collector to 1000°C. After 10 minutes, the hydrogen gas was turned off and a mixed gas composed of methane, argon and methane was introduced, wherein the proportion of methane was 5 wt%, and the relative humidity of the mixed gas was 60%. Turn on the DC negative high voltage to 9000V to form glow discharge plasma between the needle plate electrodes. After 30 minutes of discharge, turn off the DC negative hi...

Embodiment 3

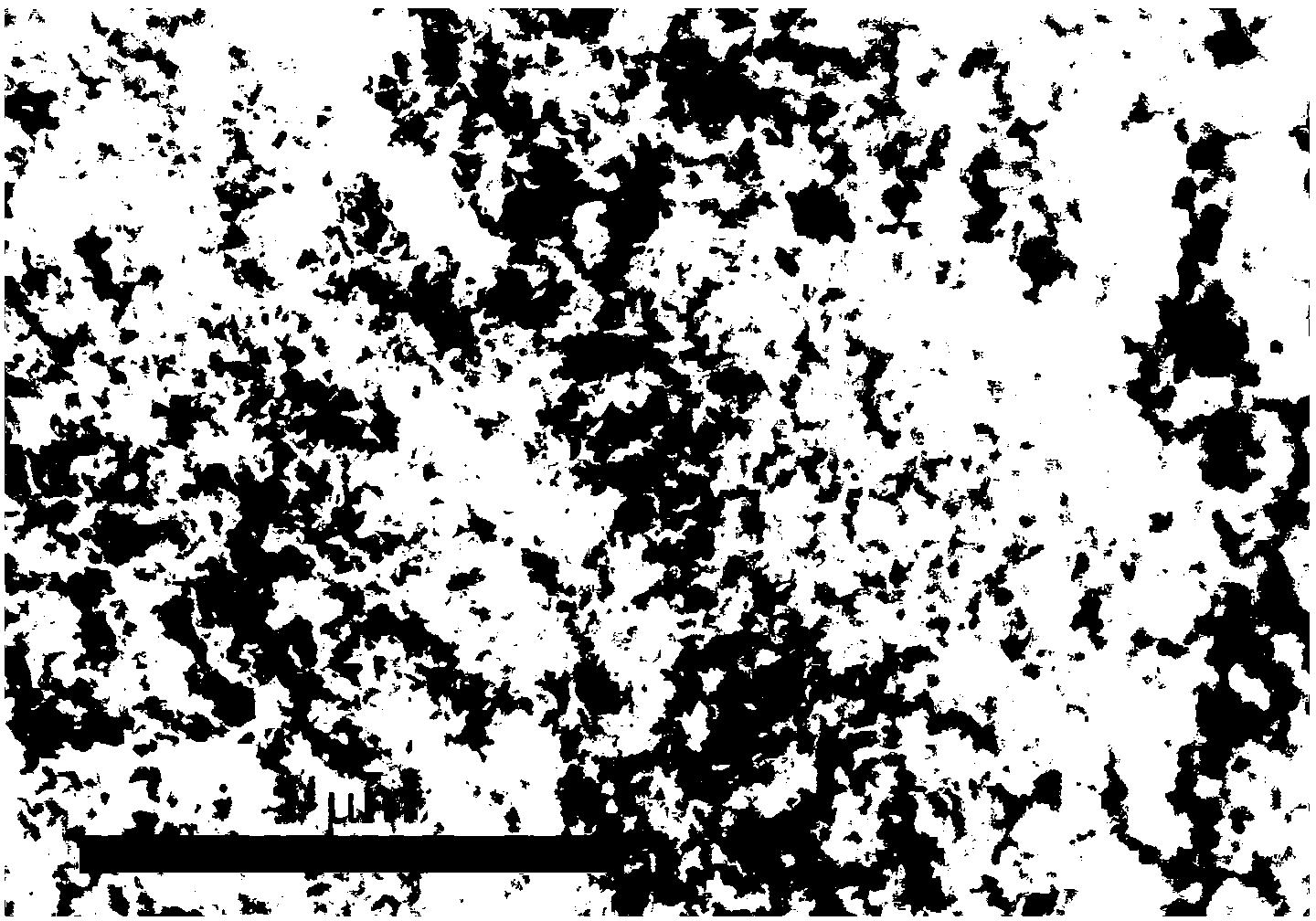

[0039] Example 3: Copper sheet current collector with vertically oriented graphene surface modification.

[0040] A pair of needle-plate electrodes are arranged in the quartz tube, the needle electrodes are connected to DC negative high voltage, and the plate electrodes are grounded. The quartz tube is placed in a temperature-controlled heating furnace, with one end ventilated and the other end open. Put the copper sheet current collector on the flat electrode, pass hydrogen gas into the ventilation end, and turn on the heating furnace to heat the nickel foam current collector to 800°C. After 10 minutes, turn off the hydrogen and feed a mixed gas composed of acetylene, helium and water vapor, wherein the proportion of acetylene is 20wt%, and the relative humidity of the mixed gas is 30%. Turn on the DC negative high voltage to 12000V to form glow discharge plasma between the needle plate electrodes. After 10 minutes of discharge, turn off the DC negative high voltage, turn o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com