Methyl methacrylate (MMA) / bismaleimide (BMI) copolymer organic resistive random access memory and preparation method thereof

A technology of resistive variable memory and resistive variable memory, which is applied in the field of microelectronics, can solve the problems of poor chemical stability and thermal stability, and achieve the effects of easy preparation, simple process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

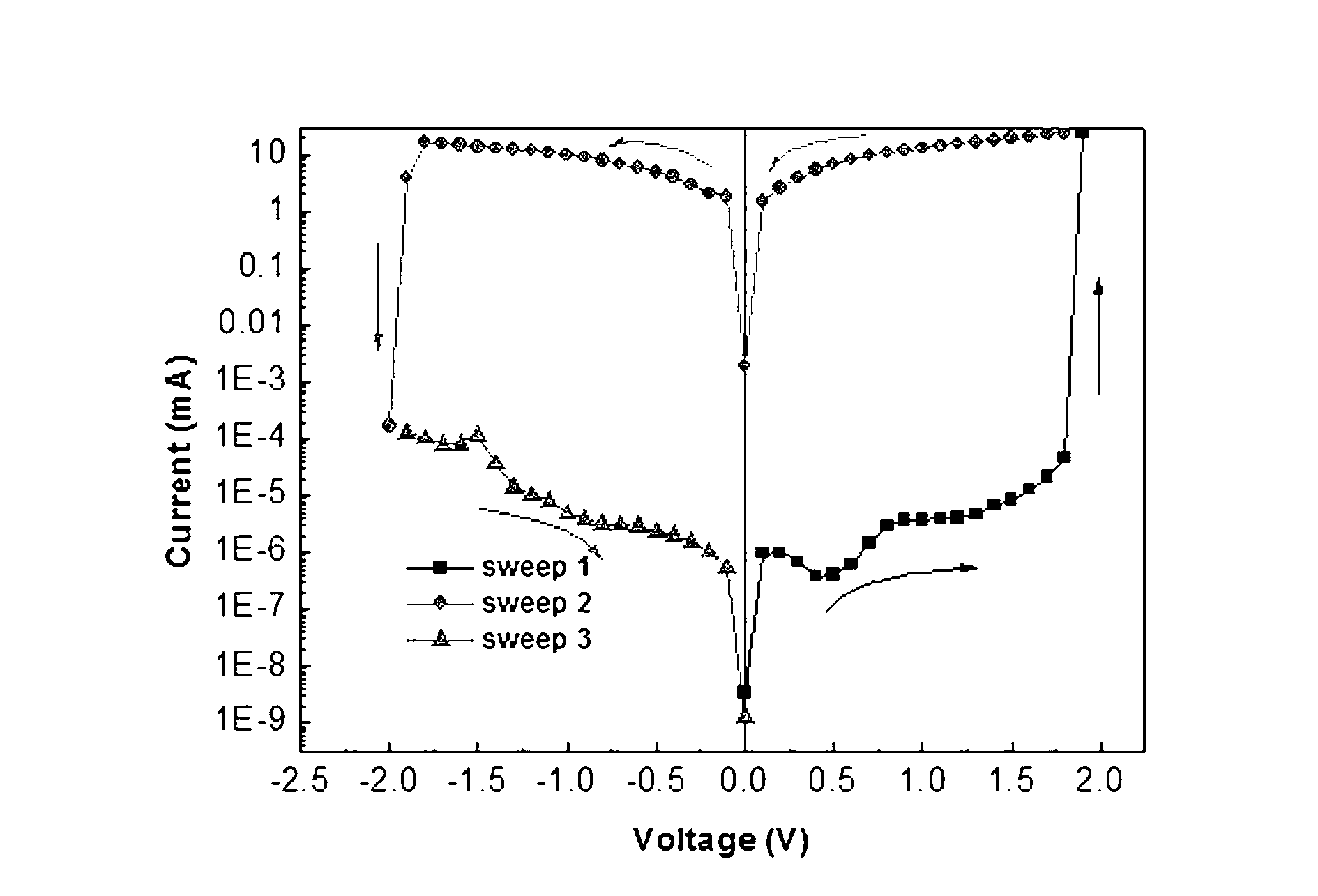

Embodiment 1

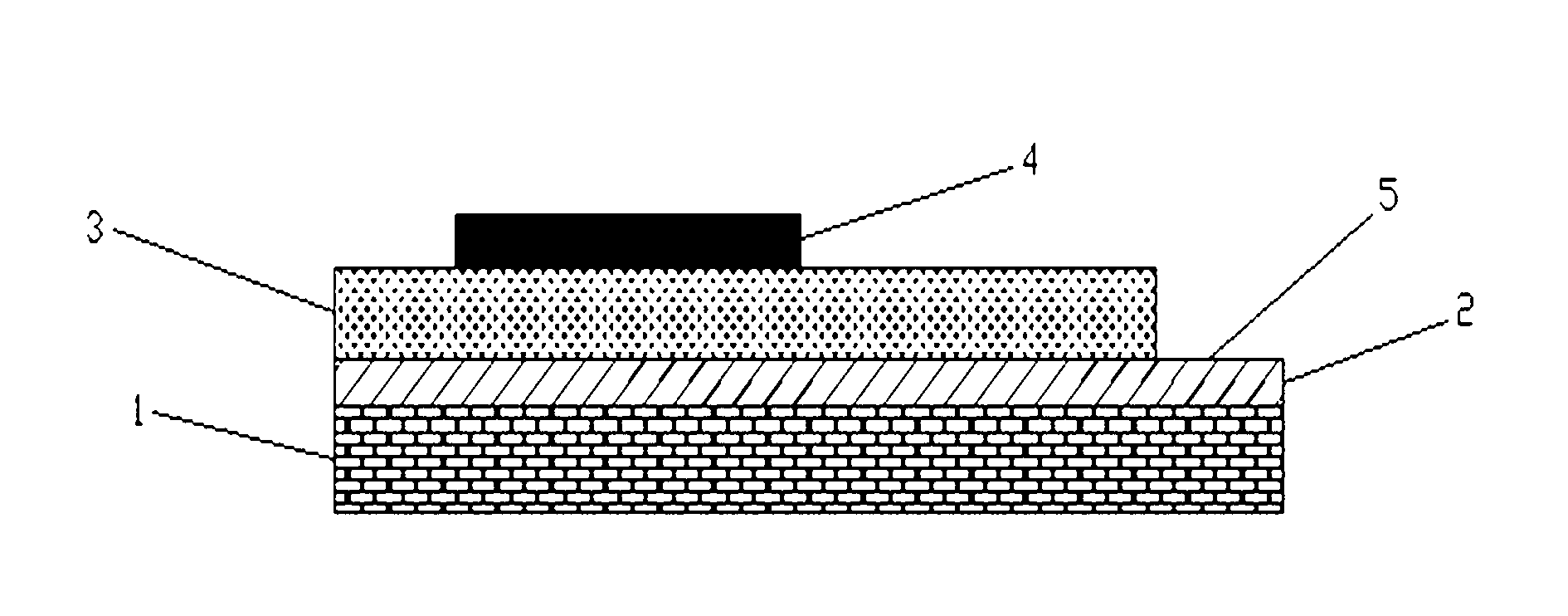

[0033] A preparation method of an MMA / BMI copolymer organic resistive variable memory, comprising the steps of:

[0034] (1) Ultrasonic clean the indium tin oxide (ITO) glass substrate with deionized water, alcohol, and acetone for 15 minutes, and dry it as the bottom electrode for later use. The thickness of the indium tin oxide is 250nm;

[0035] (2) Preparation of MMA / BMI prepolymer: Blend 0.2g of BMI and 10ml of MMA, add 5ml of chloroform as a polar solvent, then mix well on a magnetic stirrer, add 0.0102g of initiator BPO (benzyl peroxide acyl) or AIBN (azobisisobutyronitrile), heated to 75°C and stirred for 3 hours, then raised to 110°C and stirred for 15 minutes to obtain a prepolymerized solution of MMA / BMI copolymer;

[0036] (3) Spin-coat the prepolymerization solution in step (2) twice to deposit on the bottom electrode, and then place it on a 100°C electric heating plate to dry for 5 minutes to form an MMA / BMI prepolymer organic film;

[0037] (4) Cover the prepol...

Embodiment 2

[0041] A preparation method of an MMA / BMI copolymer organic resistive variable memory, comprising the steps of:

[0042] (1) Ultrasonic clean the indium tin oxide (ITO) glass substrate with deionized water, alcohol, and acetone for 15 minutes, and dry it as the bottom electrode for later use. The thickness of the indium tin oxide is 250nm;

[0043] (2) Preparation of MMA / BMI prepolymer: Blend 0.4g of BMI and 10ml of MMA, add 8ml of chloroform as a polar solvent, then mix well on a magnetic stirrer, add 0.0104g of initiator BPO (benzyl peroxide acyl) or AIBN (azobisisobutyronitrile), the temperature was raised to 80°C and stirred for 3 hours, and then the temperature was raised to 115°C and stirred for 15 minutes to obtain a prepolymerized solution of MMA / BMI copolymer;

[0044](3) Spin-coat the prepolymerization solution in step (2) twice to deposit on the bottom electrode, and then dry it on a 110°C electric heating plate for 5 minutes to form an MMA / BMI prepolymer organic fi...

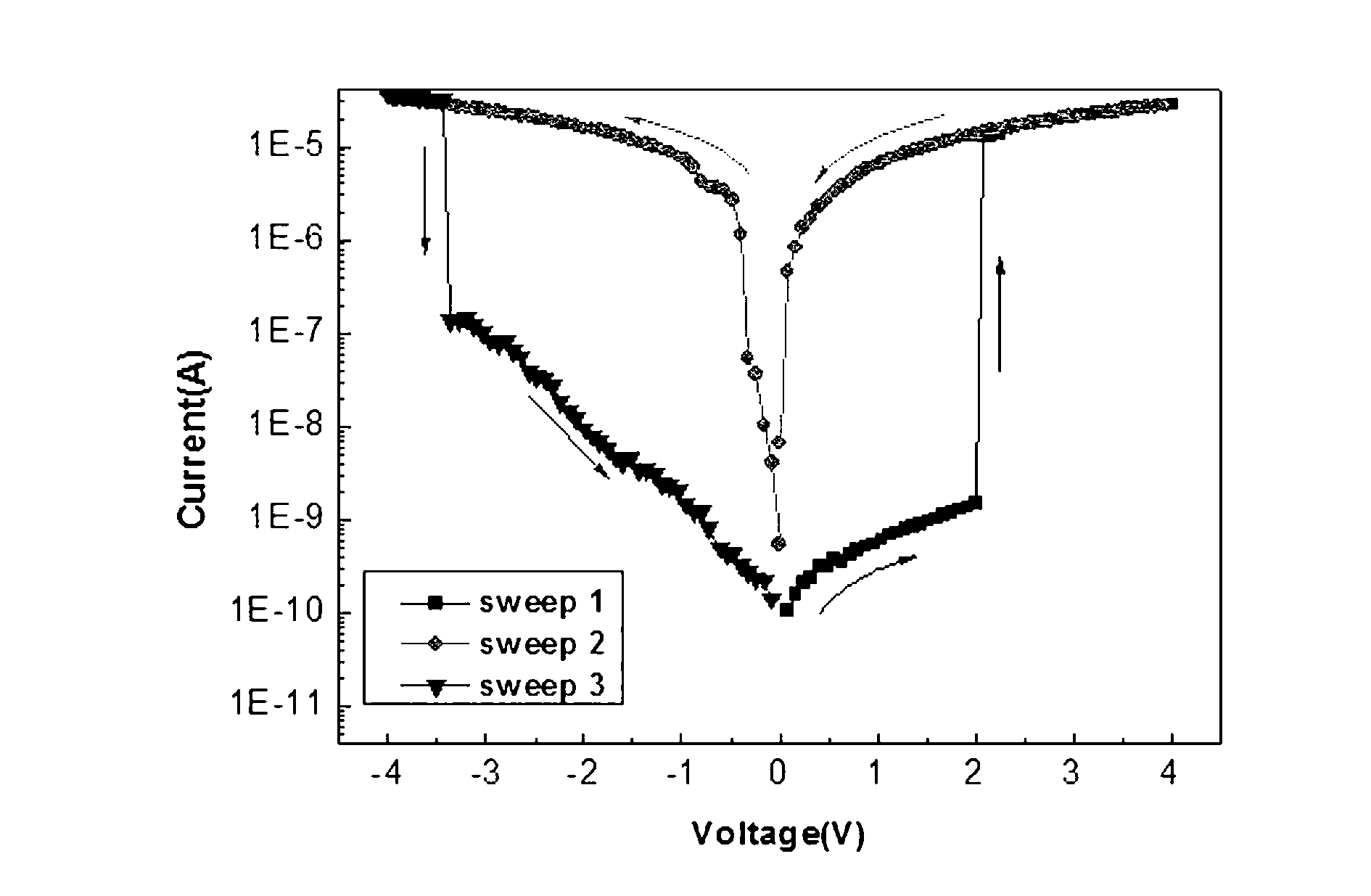

Embodiment 3

[0049] A preparation method of an MMA / BMI copolymer organic resistive variable memory, comprising the steps of:

[0050] (1) Ultrasonic clean the indium tin oxide (ITO) glass substrate with deionized water, alcohol, and acetone for 15 minutes, and dry it as the bottom electrode for later use. The thickness of the indium tin oxide is 250nm;

[0051] (2) Preparation of MMA / BMI prepolymer: Blend 0.6g of BMI and 10ml of MMA, add 10ml of chloroform as a polar solvent, then mix well on a magnetic stirrer, add 0.0106g of initiator BPO (benzyl peroxide acyl) or AIBN (azobisisobutyronitrile), the temperature was raised to 85°C and stirred for 3 hours, and then the temperature was raised to 120°C and stirred for 15 minutes to obtain a prepolymerized solution of MMA / BMI copolymer;

[0052] (3) The prepolymer in step (2) was spin-coated twice to deposit on the bottom electrode, and then dried on a 110°C electric heating plate for 5 minutes to form an MMA / BMI prepolymer organic film;

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap