Coryneform bacterium transformant and method for producing phenol using same

一种棒状细菌、制造方法的技术,应用在苯酚的制造领域,能够解决尚未获知苯酚生产率、尚未报道苯酚生产菌等问题,达到高效生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0150] As the method for preparing the reaction solution under reducing conditions, known methods can be used without limitation. For example, an aqueous solution for the reaction liquid can be used instead of distilled water or the like as a liquid medium for the reaction liquid. For the preparation method of the aqueous solution for the reaction liquid, refer to the culture solution preparation method for absolute anaerobic microorganisms such as sulfuric acid reducing microorganisms (Pfennig, N et.al. (1981): The dissimilatory sulfate-reducing bacteria, In The Prokaryotes, A Handbook on Habitats, Isolation and Identification of Bacteria, Ed.by Starr, M.P.et.al.p.926-940, Berlin, Springer Verlag.) or " Agrochemical Experiment Book Volume 3, edited by the Agrochemical Department of the Faculty of Agriculture, Kyoto University, 26th printing in 1990, published by Sangyo Shoshu Co., Ltd., etc., can obtain an aqueous solution under desired reducing conditions.

[0151] Specifica...

Embodiment 1

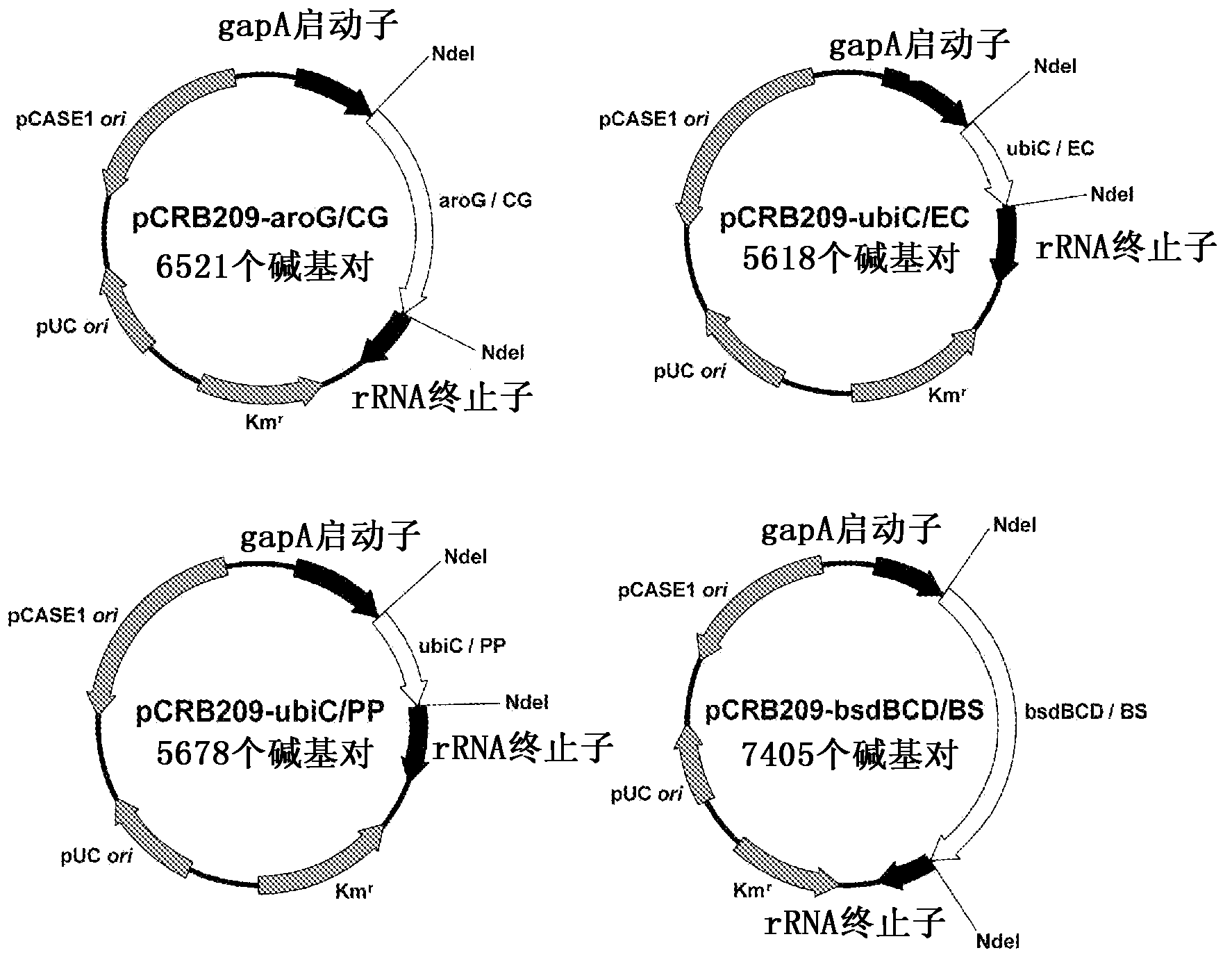

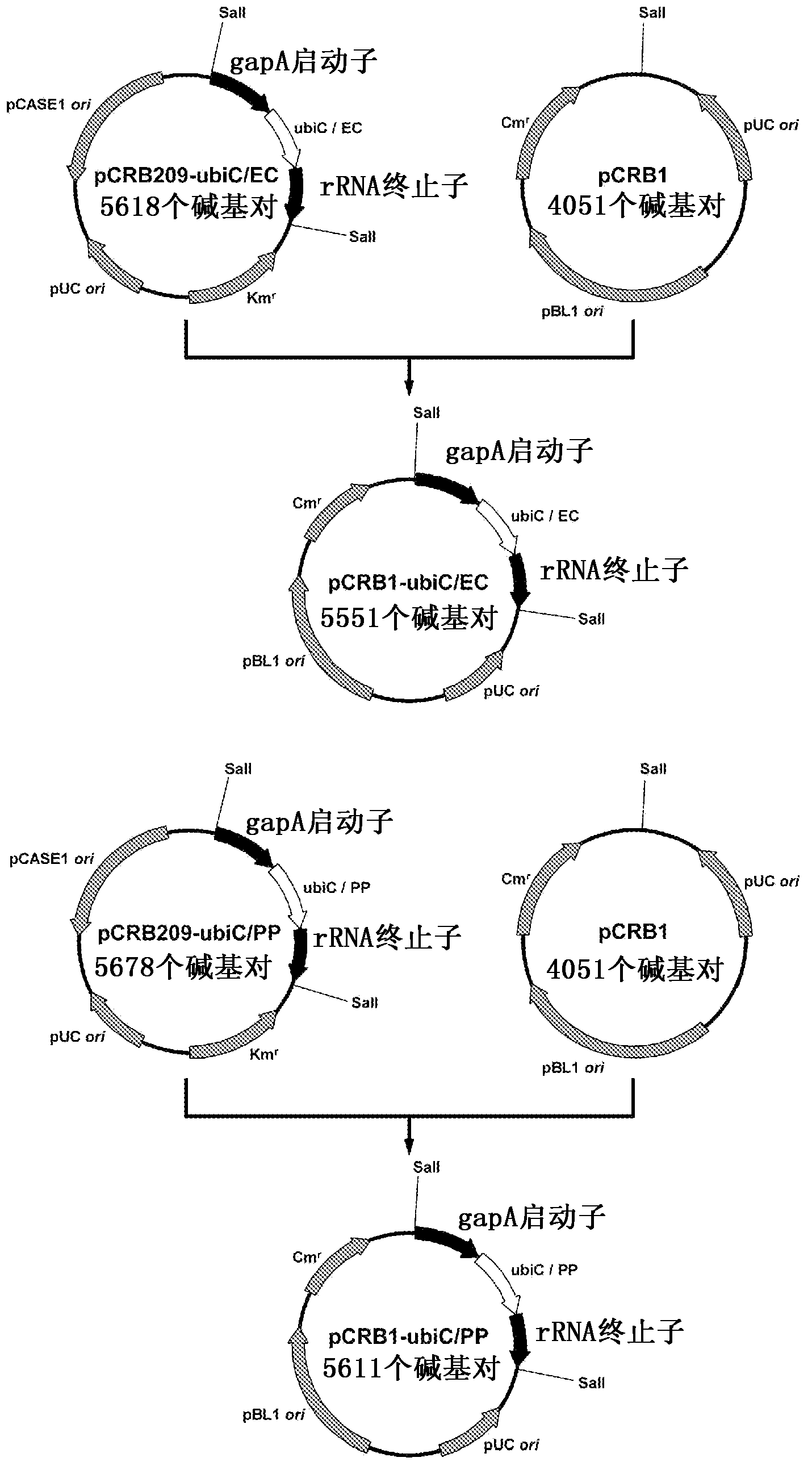

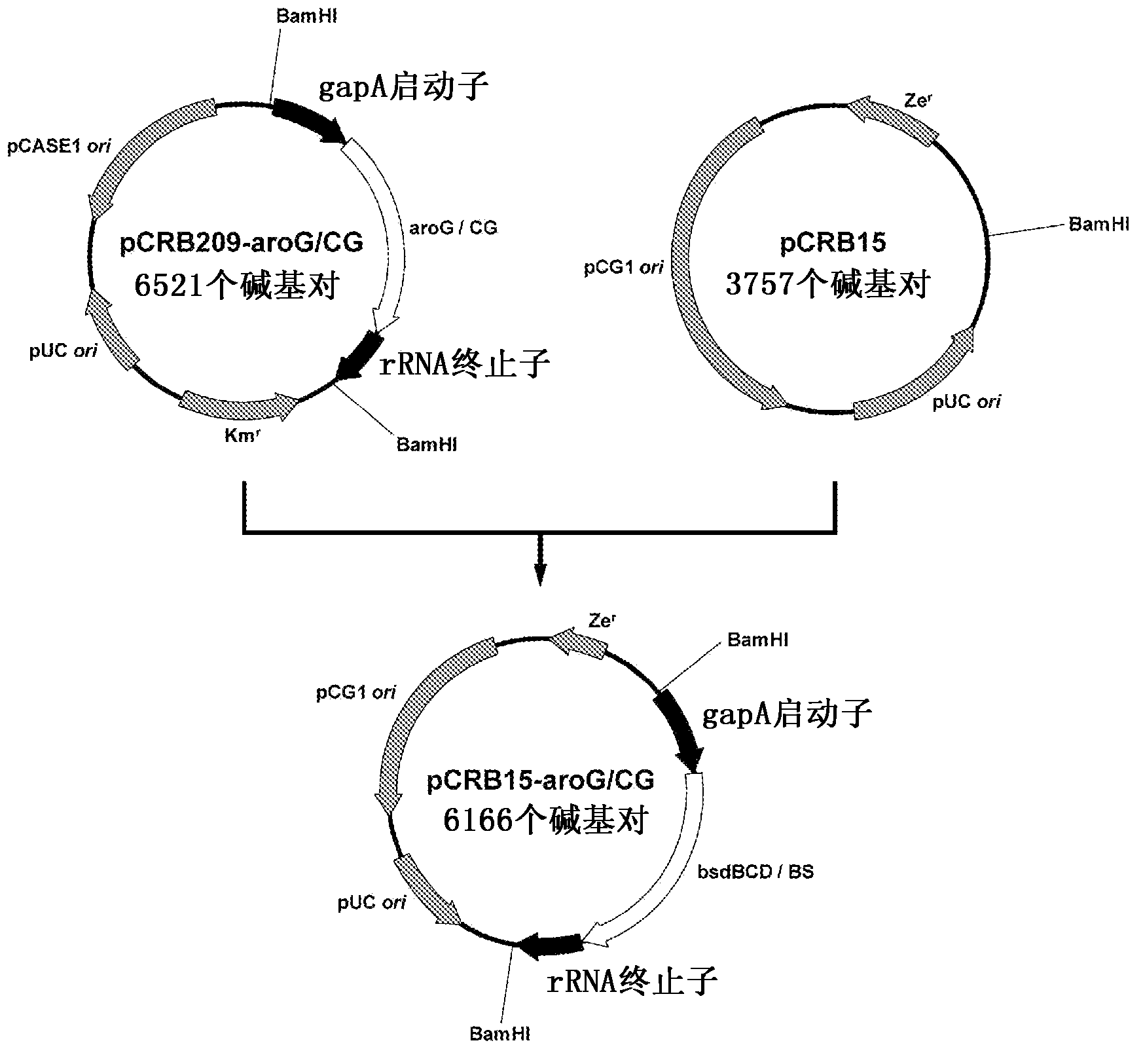

[0158] Cloning and expression of embodiment 1 phenol production gene

[0159] (1) Extract chromosomal DNA from microorganisms

[0160] The operation of extracting chromosomal DNA from Corynebacterium glutamicum (Corynebacterium glutamicum) R (FERM P-18976) was carried out as follows: to A medium [Will (NH 2 ) 2 CO2g, (NH 4 ) 2 SO 4 7g, KH 2 PO 4 0.5g, K 2 HPO 4 0.5g, MgSO 4 ·7H 2 O0.5g, 0.06% (w / v) Fe 2 SO 4 ·7H 2 O+0.042%(w / v)MnSO 4 2H 2 O1ml, 0.02% (w / v) biotin solution 1ml, 0.01% (w / v) thiamine solution 2ml, yeast extract 2g, vitamin analysis casein hydrolyzate 7g dissolved in 1L distilled water] add the final concentration of 4% 50% (w / v) glucose solution was used as a carbon source, and after inoculation with a platinum loop, shaking culture was carried out at 33°C until the logarithmic growth phase. After the bacteria were collected, DNA genome extraction kit (trade name: GenomicPrep Cell and Tissue DNA Isolation Kit, manufactured by Amersia Co., Ltd....

Embodiment 2

[0756] Example 2 Corynebacterium glutamicum phenol production gene introduction strain and by-product pathway disruption strain The phenol formation experiment

[0757] The production of phenol was compared with the Corynebacterium glutamicum phenol gene-transferred strain PHE11-PH18 produced in Example 1.

[0758] Each Corynebacterium glutamicum phenol gene introduction strain (PHE11-PH18) is spread to the A agar medium containing the antibiotic shown in table 2 [will (NH 2 ) 2 CO2g, (NH 4 ) 2 SO 4 7g, KH 2 PO 4 0.5g, K 2 HPO 4 0.5g, MgSO 4 ·7H 2 O0.5g, 0.06% (w / v) Fe 2 SO 4 ·7H 2 O+0.042%(w / v)MnSO 4 2H 2 O1ml, 0.02% (w / v) biotin solution 1ml, 0.01% (w / v) thiamine solution 2ml, yeast extract 2g, vitamin analysis casein hydrolyzate 7g, glucose 40g, agar 15g suspended in 1L distilled water Middle], at 28°C in the dark for 20 hours.

[0759] The Corynebacterium glutamicum phenol gene introduction strain that grows in the above-mentioned petri dish of a platin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com