Preparation method for silver-coated silicon dioxide composite microsphere particles

A technology of composite microspheres and silica, applied in the field of nanomaterials, can solve the problems of the uniformity and compactness of the coating layer, and achieve compactness and uniformity, avoid agglomeration, and have good monodispersity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] ①Preparation of nano-silica particles

[0038] Mix 0.15ml of tetraethyl orthosilicate and 0.55ml of absolute ethanol evenly to obtain a silicon source mixture, which is transferred to a dropping funnel; 6ml of 25% ammonia water and 20ml of absolute ethanol Mix in a two-necked flask to obtain the mixed solution B, magnetic stirring, the magnetic sub-rotation speed is 250rpm (the magnetic sub-rotation speed can also be 200 or 300rpm), and the water bath is heated while stirring, and the water bath temperature is 25°C (the water bath temperature can also be 20 or 40°C), while heating in a water bath, add the silicon source mixed solution to the mixed solution B drop by drop at a rate of 0.3d / s (the drop rate can also be 0.1 or 0.5d / s); after the addition is complete , stirred for 2 hours, and then centrifuged, the centrifugation time was 20min, the speed was 5000rpm, the precipitate obtained by centrifugation was ultrasonically dispersed, washed with distilled water, and t...

Embodiment 2

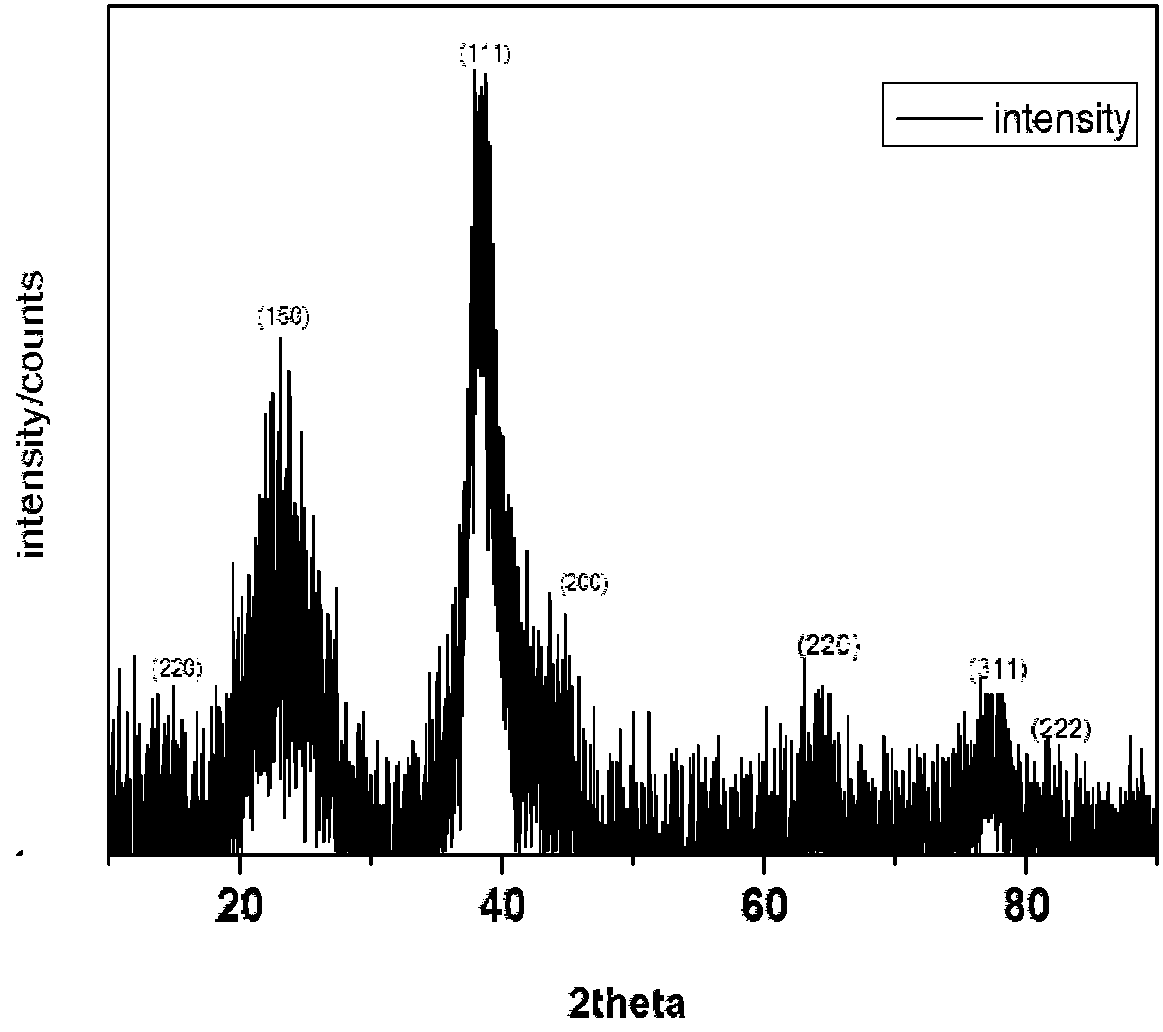

[0045] The heating temperature of the water bath for preparing the composite microsphere particle solution in step ② of this embodiment is 30° C., and the addition amount and operation steps of other reagents are the same as those of the first embodiment. image 3 It is the XRD spectrum of the silver-coated silica composite microsphere particles in this example. In the X-ray diffraction spectrum, there are diffraction peaks corresponding to silica and silver at 2θ at 10° to 80°, and there is a diffraction peak at 2θ=23°. Diffuse peak, which is a standard characteristic peak of silica, and its crystal form is amorphous like traditional silica gel. At the same time, the last five peaks correspond to the (111), (200), (220), (311) and (222) crystal planes of cubic silver respectively, indicating that the silver in the silicon shell exists in the form of a simple substance with a face center Cubic structure. Figure 4 It is the absorption spectrum of the silver-coated silica comp...

Embodiment 3

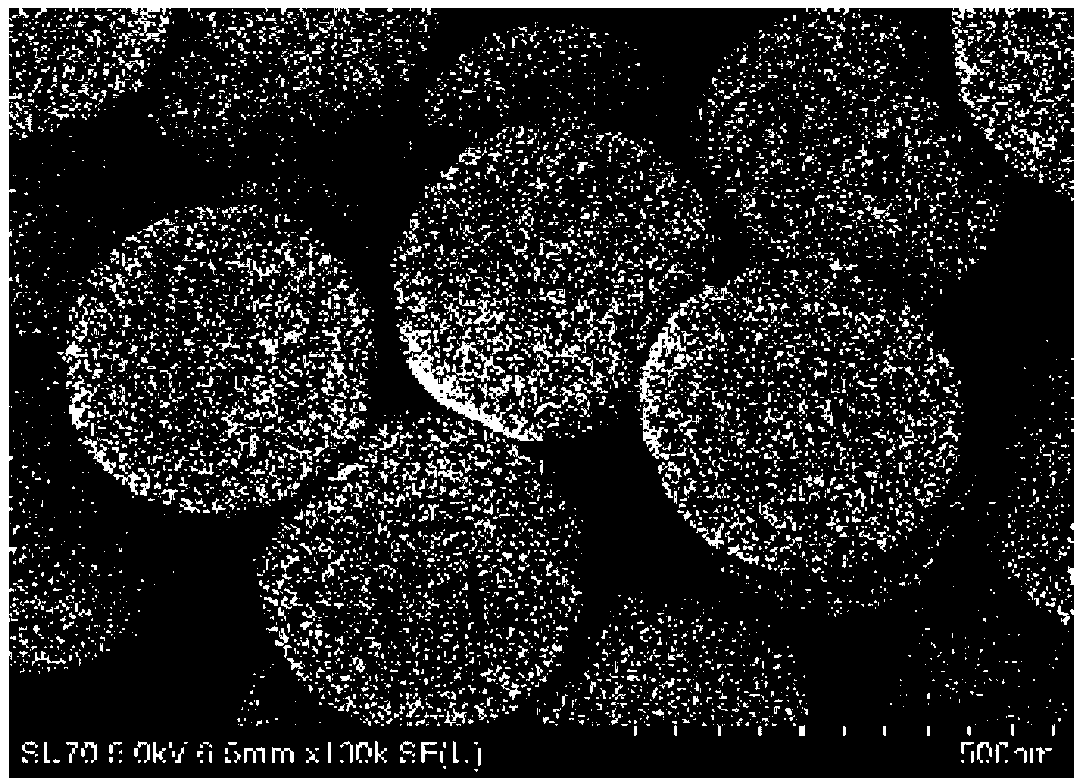

[0047] The heating temperature of the water bath for preparing the composite microsphere particle solution in step ② of this embodiment is 70° C., and the addition amount and operation steps of other reagents are the same as those of the first embodiment. Figure 6 It is a scanning electron microscope (SEM) image of silver-coated silica composite microsphere particles in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com