Cathode material for medium temperature solid oxide fuel battery, and preparation thereof

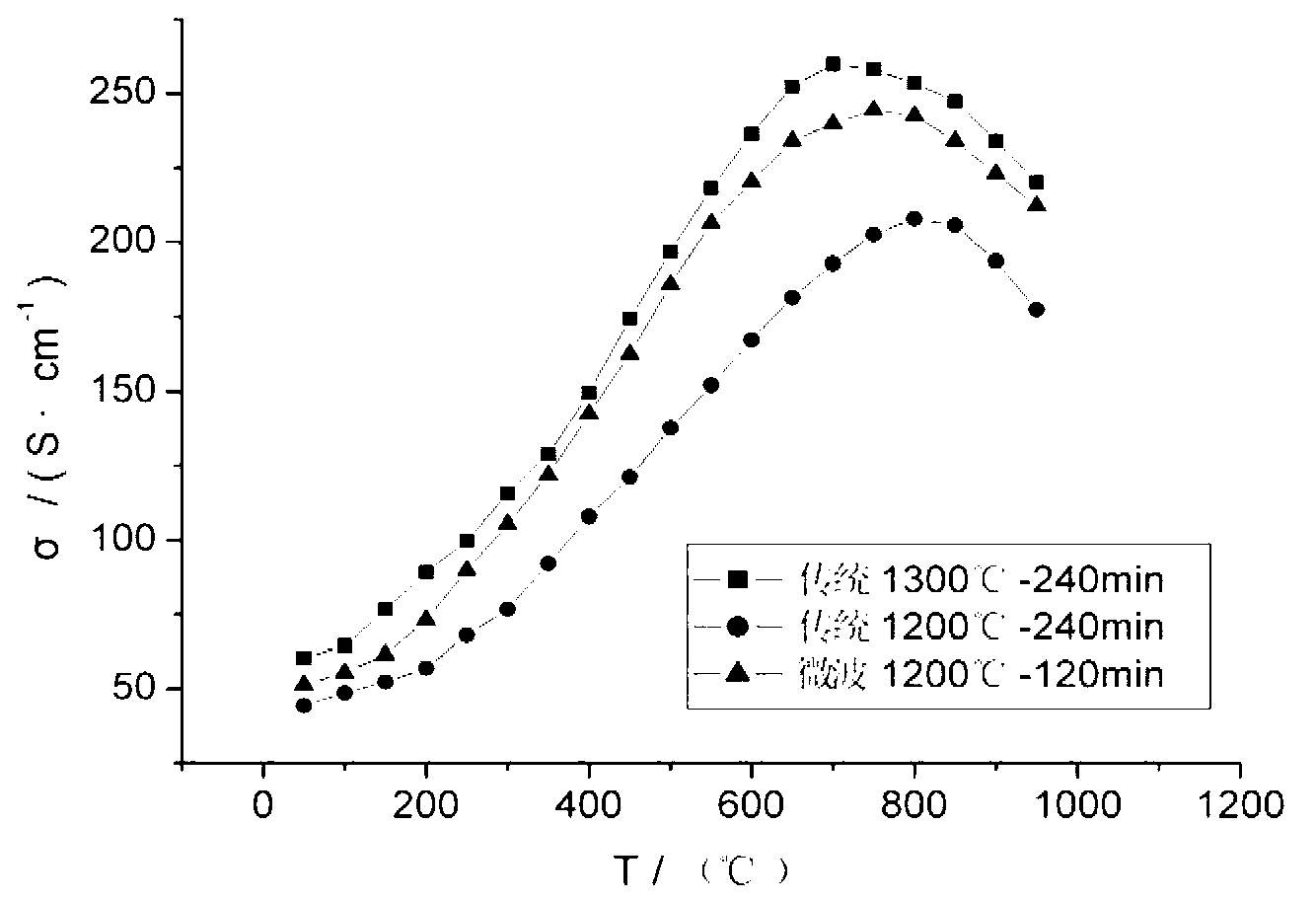

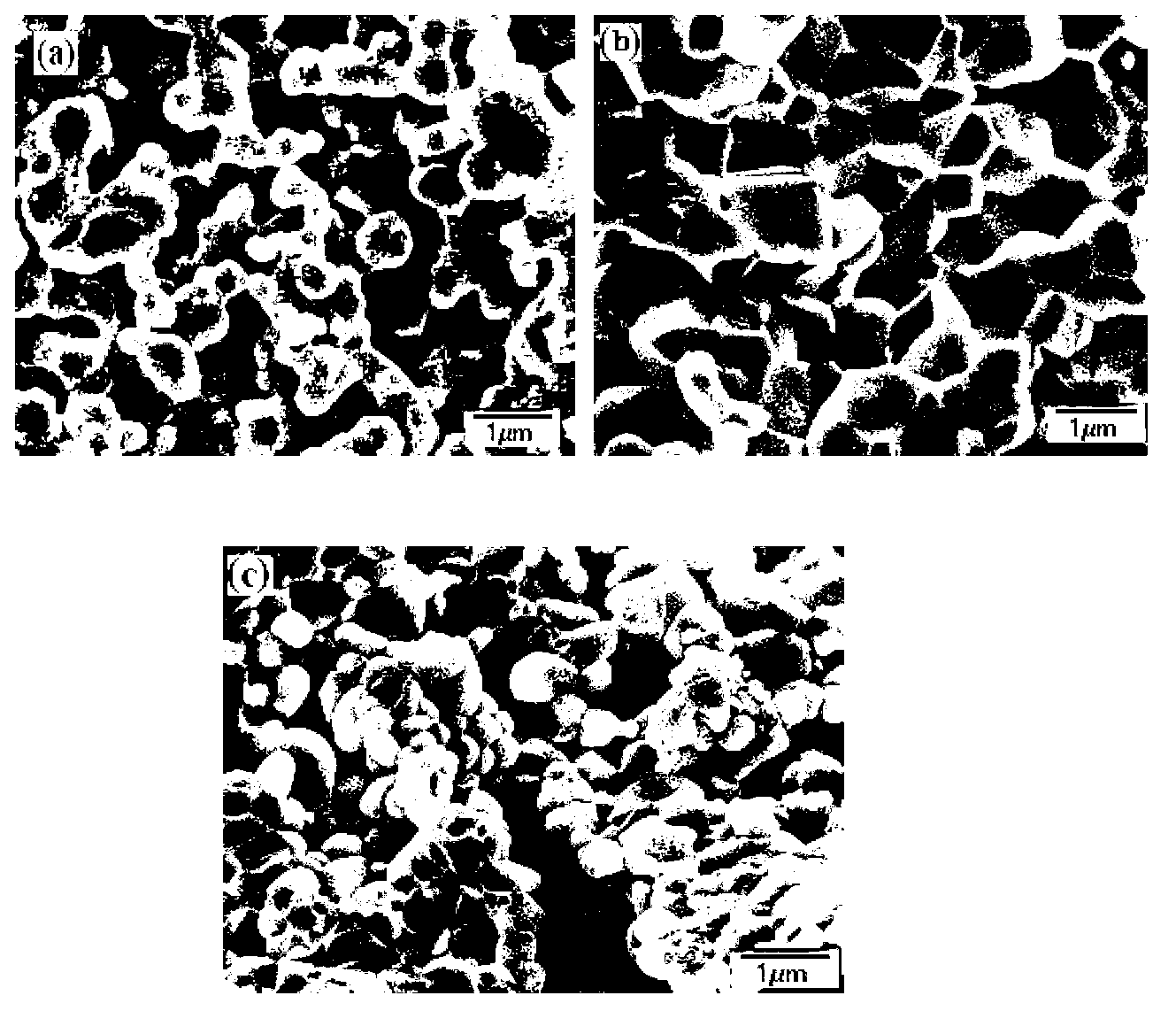

A solid oxide and cathode material technology, applied in battery electrodes, iron compounds, circuits, etc., can solve the problems of poor material homogeneity, high sintering temperature, and high energy consumption, and achieve high electrical conductivity, low sintering temperature, and energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A kind of cathode material for intermediate temperature solid oxide fuel cell, is lanthanum ferrite base cathode material, and its chemical formula is La 0.7 Sr 0.3 Fe 0.8 Cu 0.2 o 2.75(LSFC-32); its preparation method, the steps are as follows:

[0024] 1) Firstly, the raw materials are pretreated

[0025] Raw materials include lanthanum oxide (La 2 o 3 ), strontium carbonate (SrCO 3 ), iron oxide (Fe 2 o 3 ) and copper oxide (CuO), the pretreatment process of the raw materials is as follows: the heating temperature of lanthanum oxide is 900°C, and the heat preservation is 60 minutes; the heating temperature of other raw materials is 350°C, and the heat preservation is 120 minutes;

[0026] 2) The raw materials are weighed according to the LSFC stoichiometric ratio. After the weighed raw materials are fully mixed and ground, they are put into a microwave sintering furnace for pre-sintering. ℃ / min speed up to 850°C, keep warm for 20 minutes, and finally rise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com