Process method for rapidly drying grains through countercurrent gas flow

A technology of rapid drying and process method, which is applied in the direction of saving seeds through drying, adapting to climate change, etc., and can solve problems such as difficult to improve the efficiency and capacity of drying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

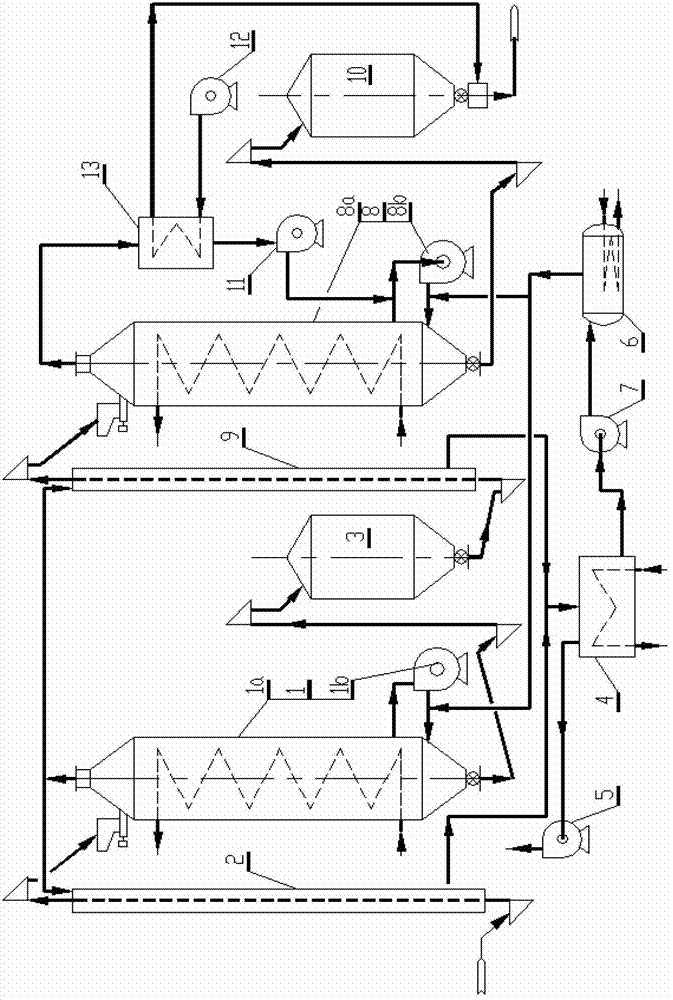

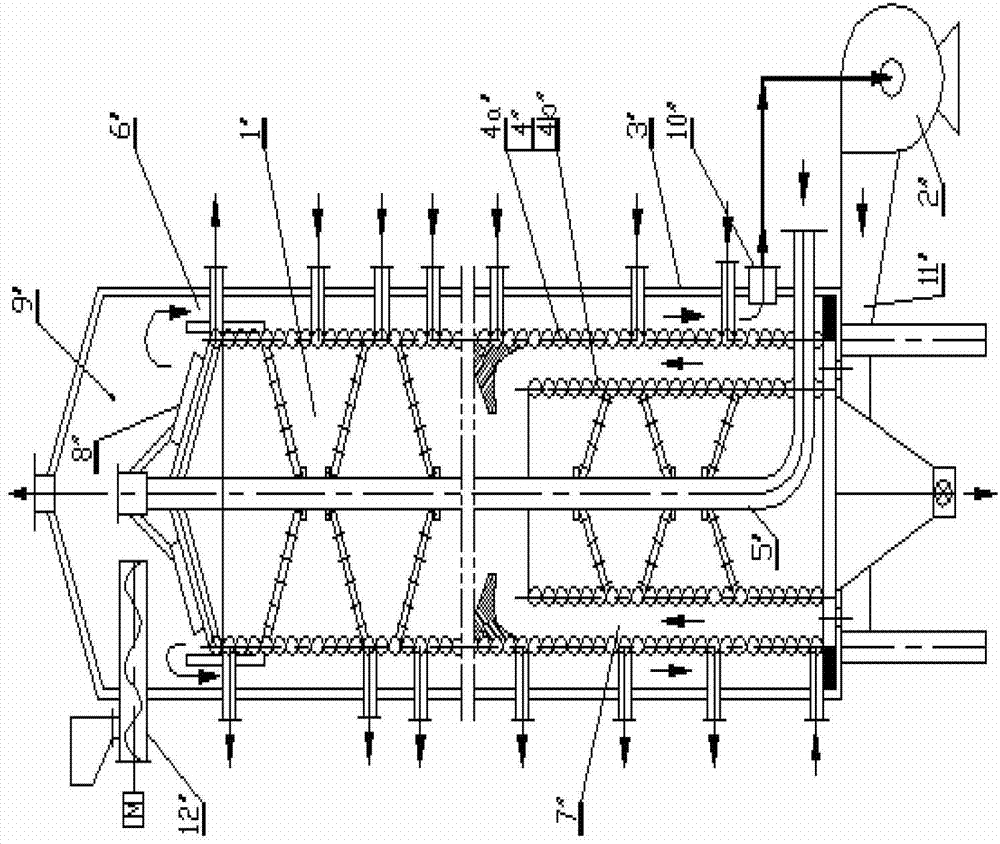

[0062] The present invention relates to a process method for rapid drying of grains with countercurrent airflow. The process flow and specific implementation manners thereof are:

[0063] According to the characteristics, moisture content and drying capacity of the grains to be dried, according to the process method and main equipment performance of the present invention, an operating system that conforms to its process flow is designed and composed. The operating system needs to have flexible process adaptability and Efficient drying capacity, and meets the requirements of energy saving and consumption reduction, safety and environmental protection.

[0064] Depending on the nature of the grain or the drying process, the operating system designed according to the process method described can be used as two operating systems with different operating modes. One is an operating system for two-stage drying of grains, and the other It is an operating system for single-stage drying of g...

Embodiment 1

[0085] The grain to be dried is rice with a moisture content of 30%. The moisture content of the dried rice is required to be less than 13%. The drying capacity of the process operation system is 20 tons / hour.

[0086] The characteristics of dried grains are: the drying of non-breeding rice is mainly to remove the external moisture and part of the internal moisture. The main part is the external moisture that is easy to remove. Although the internal moisture is small and the rice grains are relatively small, it is because of the rice Shell coating makes it difficult for the internal moisture to escape quickly. At the same time, if the working temperature of the drying medium is too high, it will crack or break the rice in the later stage of drying. The temperature of the rice will exceed 45℃, and its external and internal quality will be reduced, so drying The temperature of the drying medium and heating conditions need to be restricted during the process. In addition, due to the...

Embodiment 2

[0114] The grain to be dried is corn with a moisture content of 25%. The moisture content of the dried corn is required to be less than 12%. The drying capacity of the process operating system is 20 tons / hour.

[0115] The characteristics of the dried grains are: the drying of non-breeding corn is mainly to remove the external moisture and part of the internal moisture, but the corn grains are large and dense, and the internal moisture is difficult to quickly escape, and the working temperature of the drying medium will cause drying. After the corn skin becomes hard and cracks, the temperature of corn exceeds 60 ℃, its external quality and internal quality will be reduced, so the drying process needs to limit the drying medium temperature and heating conditions. In addition, due to the limitations of the conditions of the grain drying treatment site, the corn cannot be properly preheated before the drying treatment. For this reason, it is necessary to adopt a two-stage drying pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com