Method for stabilizing product quality of sodium bicarbonate injection

A technology of sodium bicarbonate and product quality, applied in the field of injections, can solve the problems of chipping, product quality change, loss, etc., and achieve the effects of simple operation, guaranteed product quality, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

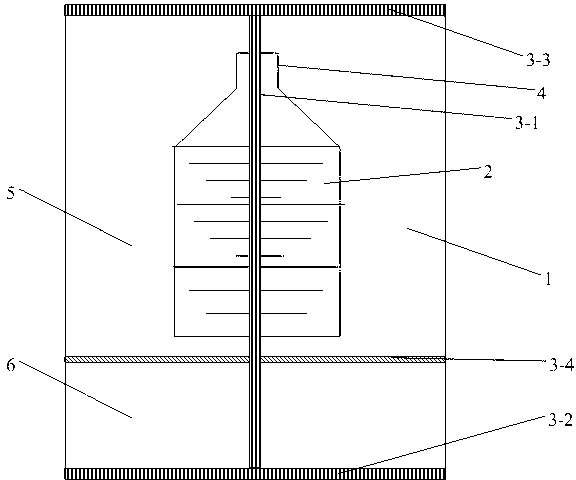

[0017] Example 1: Such as figure 1 The plastic bottle sodium bicarbonate injection packaging structure shown in Example 1 of the present invention mainly includes infusion bottle packaging 2 and oxygen barrier packaging bag 1. The infusion bottle packaging 2 uses polypropylene infusion bottles and oxygen barrier packaging bags 1 is a PVDC multi-layer co-extrusion blown film packaging bag, wherein the infusion bottle packaging 2 includes a bottle body and a bottle cap 4, and the oxygen barrier packaging bag 1 has four seals, namely the first seal 3-1, The second seal 3-2, the third seal 3-3, and the fourth seal 3-4, of which the first seal 3-1, the second seal 3-2, and the third seal 3-3 will co-extrusion rectangular PVDC multilayers The plastic film packaging bag is plastic-sealed to form the oxygen barrier packaging bag 1. The fourth seal 3-4 divides the inner cavity of the formed oxygen barrier packaging bag 1 into an upper cavity 5 and a lower cavity 6, and the upper cavity 5...

Embodiment 2

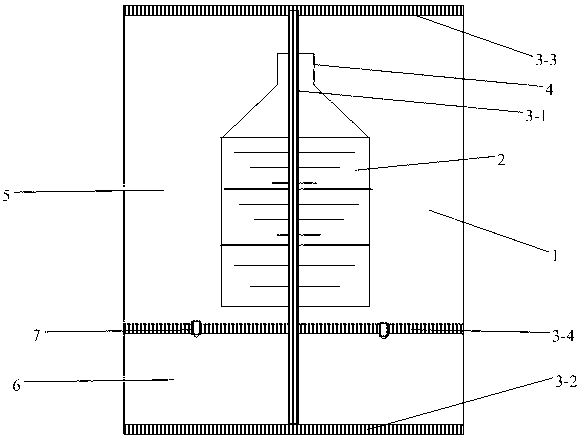

[0018] Example 2: Such as figure 2 The difference between the plastic bottle sodium bicarbonate injection packaging structure of Example 2 of the present invention and Example 1 is that the oxygen barrier packaging bag 1 has four seals, respectively the first seal 3 -1, the second seal 3-2, the third seal 3-3, and the fourth seal 3-4. These four seals all use the same sealing method and width to achieve the same sealing strength. In the fourth seal 3- Two vent valves 7 are provided on the symmetrical sides of the first seal 3-1 on 4, and the vent valves 7 are usually closed. When the pressure in the upper cavity 5 is caused by temperature changes or transportation extrusion When increasing continuously, the vent valve 7 will open to realize the fluid communication between the upper cavity 5 and the lower cavity 6. The opening threshold setting of the vent valve 7 can be measured and determined in advance according to different materials and different packaging sizes. The vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com