A kind of environment-friendly high cold resistance composite waterproof fabric and its production method

A production method and technology of waterproof fabrics, applied in the field of textile fabrics, can solve problems such as uncomfortable wearing, degumming, and harmfulness to human health, and achieve good durability, long service life, and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

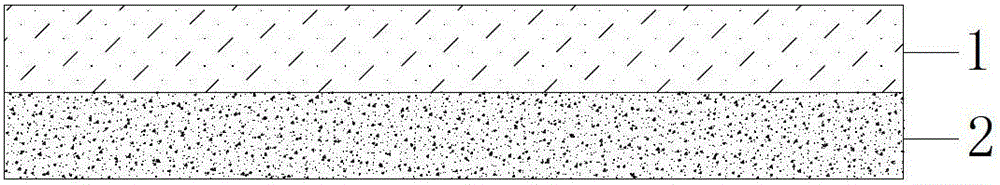

Image

Examples

Embodiment 1

[0019] 1) First, the nylon or polyester white cloth is desized, and then dyed in a dyeing factory;

[0020] 2) Three-proof treatment is carried out on the front of the dyed fabric, that is, waterproof, oil-proof and dust-proof treatment, and fabric shaping treatment, and hot-melt adhesive coating is applied on the reverse side of the fabric;

[0021] 3) Mix and stir the environment-friendly EVA particles, anti-mold agent and stabilizer into a planar shape, and roll it into an EVA film by a calender in a calendering factory. The thickness is preferably 8mm. Among them, the weight of EVA particles, anti-mold agent and stabilizer Percentage: EVA particles 97%, antifungal agent 2%, stabilizer 1%;

[0022] 4) Cool the hot melt adhesive coating for 20 minutes and directly heat the EVA film at 25°C with a film laminating machine, and then laminate the film;

[0023] 5) Finished product after cooling, rolled and packaged.

Embodiment 2

[0025] 1) First, the nylon or polyester white cloth is desized, and then dyed in a dyeing factory;

[0026] 2) Three-proof treatment is carried out on the front of the dyed fabric, that is, waterproof, oil-proof and dust-proof treatment, and fabric shaping treatment, and hot-melt adhesive coating is applied on the reverse side of the fabric;

[0027] 3) Mix and stir the environment-friendly EVA particles, anti-mold agent and stabilizer into a planar shape, and roll it into an EVA film by a calender in a calendering factory. The thickness is preferably 9mm. Among them, the weight of EVA particles, anti-mold agent and stabilizer The percentages are: EVA particles 98%, antifungal agent 0.8%, stabilizer 1.2%;

[0028] 4) Cool the hot melt adhesive coating for 20 minutes and directly heat the EVA film at 28°C with a film laminating machine, and then laminate the film;

[0029] 5) Finished product after cooling, rolled and packaged.

Embodiment 3

[0031] 1) First, the nylon or polyester white cloth is desized, and then dyed in a dyeing factory;

[0032] 2) Three-proof treatment is carried out on the front of the dyed fabric, that is, waterproof, oil-proof and dust-proof treatment, and fabric shaping treatment, and hot-melt adhesive coating is applied on the reverse side of the fabric;

[0033] 3) Mix and stir the environment-friendly EVA particles, anti-mold agent and stabilizer into a planar shape, and roll it into an EVA film by a calender in a calendering factory. The thickness is preferably 10mm. Among them, the weight of EVA particles, anti-mold agent and stabilizer The percentage is: EVA particles 97.5%, antifungal agent 1.5%, stabilizer 1%;

[0034] 4) Cool the hot melt adhesive coating for 20 minutes and directly heat the EVA film at 30°C with a film laminating machine, and carry out film lamination;

[0035] 5) Finished product after cooling, rolled and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com