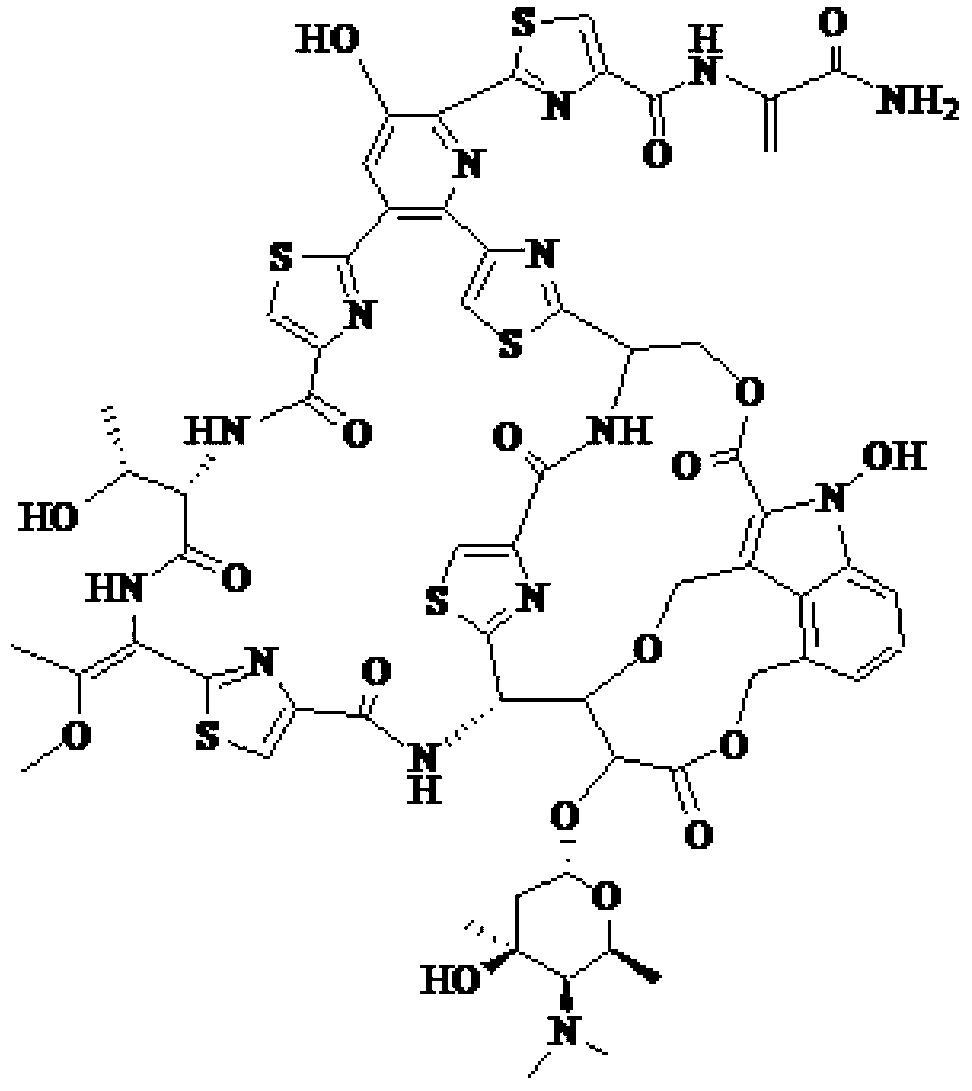

Method for separating and purifying thiopeptide antibiotic nocathiacin I through reversed-phase column

A nocafloxacin and purification method technology, which is applied in the field of separation, purification and purification of antibiotics, can solve the problems of complex structure of nocafloxacin I, low purity of nocafloxacin I, limited purification ability, etc., and achieve high product quality, Small environmental pollution and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh a certain amount of reversed-phase silica gel with a particle size of 40-75 μm, and after methanol treatment, fill and balance. Crude nocafloxacin I was dissolved in DMSO at concentrations of 25 and 150 mg / mL, respectively. Add the sample solution containing the crude product of nocafloxacin I (the mass ratio of nocafloxacin to silica gel is 1:2000--1:12000) to the top of the reversed-phase silica gel column respectively, open the valve, and wait until the sample liquid level is close to At the edge of the column surface, add about 5 times the column volume of 35% acetonitrile to elute, and then use 38% acetonitrile to elute about 4 times the column volume. Collect 38% of the acetonitrile eluate in a volume of 5-8 mL per tube, monitor in real time by thin-layer chromatography, combine all components containing nocafloxacin I, remove acetonitrile and extract with 2 times the volume of ethyl acetate, extract The liquid was evaporated to dryness to obtain high-purit...

Embodiment 2

[0031] Weigh a certain amount of reversed-phase silica gel with a particle size of 20-45 μm, and after methanol treatment, fill and balance. Crude nocafloxacin I was dissolved in DMSO at a concentration of 25 mg / mL. Add the sample solution containing nocafloxacin I crude product (the mass ratio of nocafloxacin to silica gel is 1:2000--1:12000) dropwise to the top of the reversed-phase silica gel column, open the valve, wait until the sample liquid level is close to the column At the edge of the material surface, add about 3 times the column volume of 45% acetonitrile to elute, and then use 50% acetonitrile to elute about 3 times the column volume. Collect 50% of the acetonitrile eluate with a volume of 5-8 mL per tube, monitor in real time by thin-layer chromatography, combine all components containing nocafloxacin I, remove acetonitrile and extract with 2 times the volume of ethyl acetate, extract The liquid was evaporated to dryness to obtain high-purity nocafloxacin I. Th...

Embodiment 3

[0033] Weigh a certain amount of reversed-phase silica gel with a particle size of 70-200 μm, after methanol treatment, fill and balance. Crude nocafloxacin I was dissolved in DMSO at a concentration of 25 mg / mL. Add the sample solution containing nocafloxacin I crude product (the mass ratio of nocafloxacin to silica gel is 1:12000--1:2000) dropwise to the top of the reversed-phase silica gel column, open the valve, wait until the sample liquid level is close to the column At the edge of the material surface, add about 5 times the column volume of 30% acetonitrile to elute, and then use 35% acetonitrile to elute about 3 times the column volume. Collect 35% of the acetonitrile eluate in a volume of 5-8 mL per tube, monitor in real time by thin-layer chromatography, combine all components containing nocafloxacin I, remove acetonitrile and extract with 2 times the volume of ethyl acetate, extract The liquid was evaporated to dryness to obtain high-purity nocafloxacin I. The pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com