Antibacterial polyurethane and preparation method thereof

A polyurethane and polyisocyanate technology, which is applied to polyurea/polyurethane coatings, coatings, paints containing biocides, etc., can solve the problems of expensive raw materials, complex production technology, single bactericidal and antibacterial effects, etc., and achieves low cost and simple method. Easy, source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

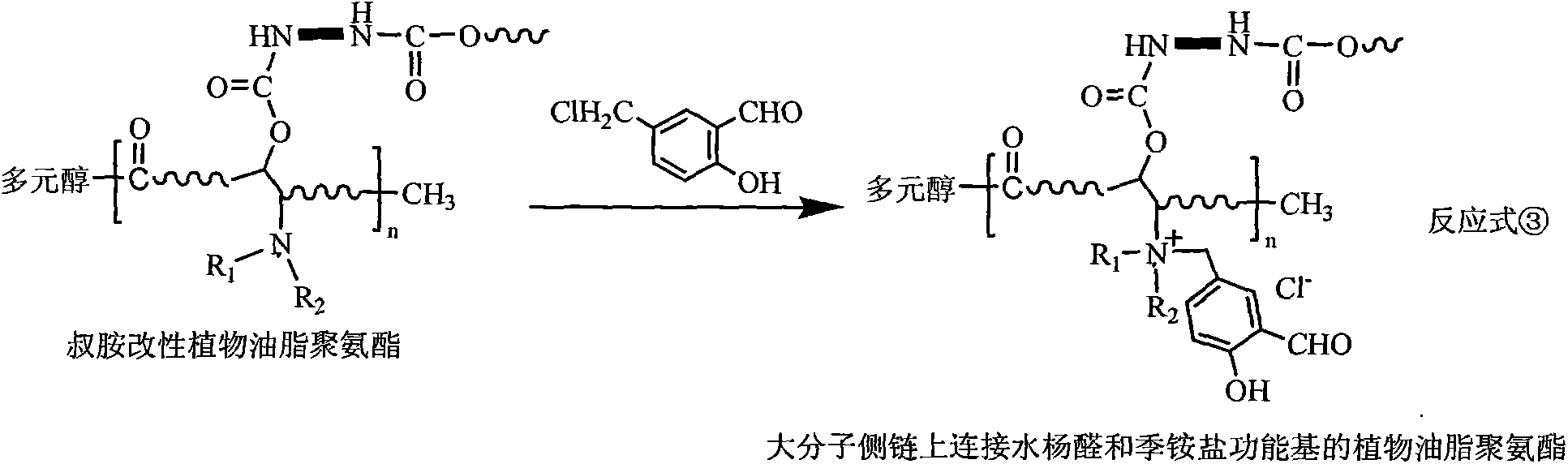

[0032] Example 1 Soybean oil-based polyurethane SO-Me connected to salicylaldehyde and quaternary ammonium salt antibacterial functional groups on the macromolecular side chain 2 Preparation of N-PUS

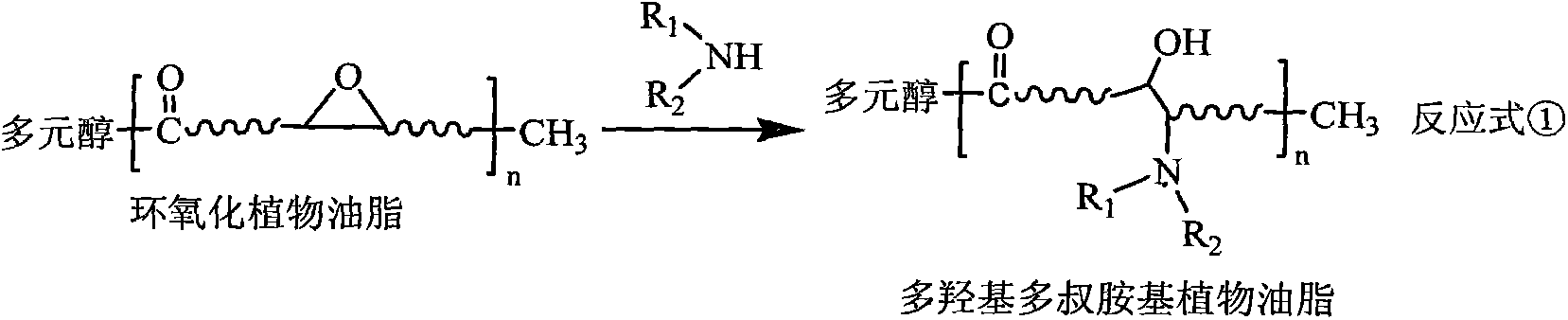

[0033]Step 1. Polyhydroxy polytertiary amine modified soybean oil SO-Mt 2 Preparation of N

[0034] Take by weighing 100 grams of epoxidized soybean oil with an epoxy value of 6.6 and 180 grams of ethyl acetate and put it into the reactor, control the temperature of the reaction material to 45-55 ° C, stir and blow 15 grams of dimethylamine gas in 2 hours, after that The reaction mass temperature rises to 80~85 ℃, continues to react for 4 hours, obtains 293 grams of light yellow polyhydroxy polytertiary amine group modified soybean oil solution, sampling analysis makes the polyhydroxy polytertiary amine group modified soybean oil hydroxyl group The value was 248.7 mg / g.

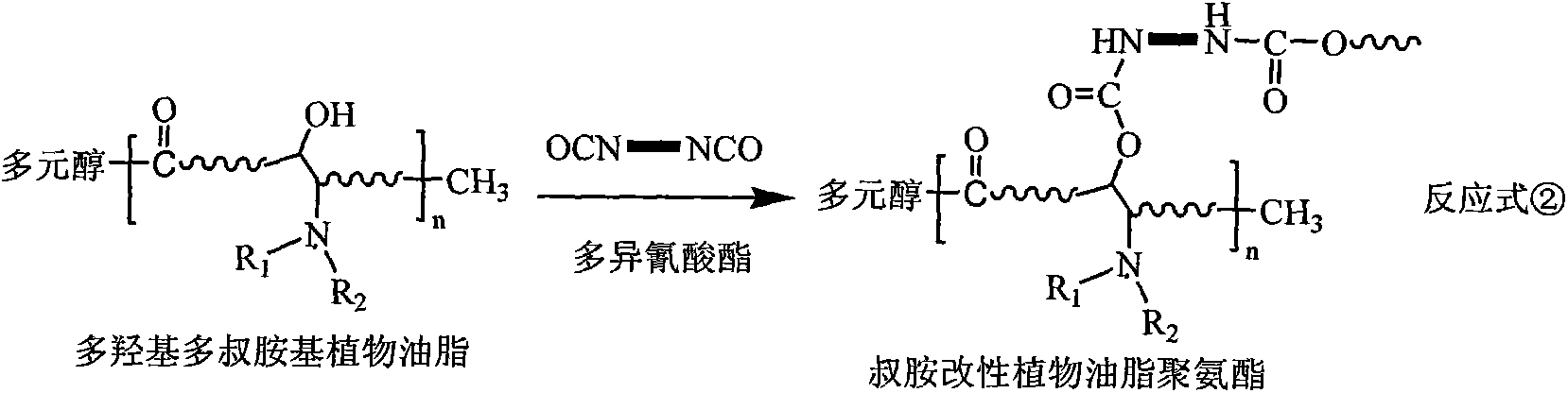

[0035] Step 2. Tertiary amine modified soybean oil-based polyurethane SO-Me 2 Preparation of N-PU

[00...

Embodiment 2

[0039] Example 2 Dioleic acid ethylene glycol ester-based polyurethane OA-Me connected to salicylaldehyde and quaternary ammonium salt antibacterial functional groups on the macromolecular side chain 2 Preparation of N-PUS

[0040] According to the method and operation steps of Example 1, the epoxidized soybean oil in Step 1 of Example 1 was replaced with epoxidized ethylene glycol dioleate, and salicylaldehyde and quaternary ammonium were connected on the macromolecular side chain Dioleate-based Polyurethane OA-Me with Salt Antibacterial Functional Group 2 Ethyl acetate solution of N-PUS.

Embodiment 3

[0041] Example 3 Soybean oil-based polyurethane SO-Ee connected to salicylaldehyde and quaternary ammonium salt antibacterial functional groups on the macromolecular side chain 2 Preparation of N-PUS

[0042] According to the method and operation steps of Example 1, the dimethylamine in Step 1 of Example 1 was replaced with diethylamine to obtain soybean oil-based polyurethane with salicylaldehyde and quaternary ammonium salt antibacterial functional groups connected to the macromolecular side chain SO-Ee 2 Ethyl acetate solution of N-PUS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com