NM400-level anti-crack high-strength wear-resistant steel and production method thereof

A high-strength wear-resistant steel and anti-crack technology, applied in the field of wear-resistant steel for mechanical engineering, can solve the problems of high cost of quenching and tempering heat treatment process, long production cycle, reduced alloy cost, etc., and achieve excellent welding performance and flame resistance. The effect of cutting crack sensitivity, simple manufacturing process and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

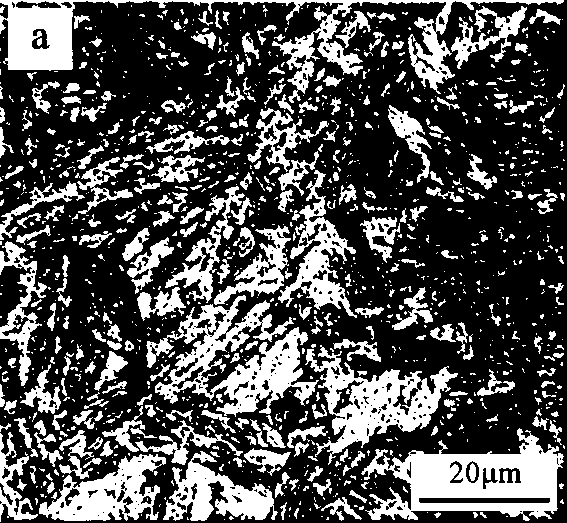

Image

Examples

Embodiment 1

[0029]A kind of NM400 crack-resistant high-strength wear-resistant steel, its components and weight percentage content: C: 0.04%, Si: 0.37%, Mn: 1.40%, Als: 0.015%, P: 0.01%, S: 0.0078%, Cr: 0.42%, Mo: 0.30%, Ti: 0.014%, B: 0.0015%, the rest are Fe and trace impurity elements, and satisfy CEV=C+Mn / 6+(V+Mo+Cr) / 5+ (Ni +Cu) / 15=0.483.

[0030] Production steps:

[0031] 1) Smelting and continuous casting into billets;

[0032] 2) Heating the billet, the heating temperature is controlled at 1190~1200°C;

[0033] 3) Rolling process: start rolling temperature 1050~1060°C, finish rolling temperature 1020~1030°C, pass reduction rate: 10%;

[0034] 4) Carry out water cooling, the starting cooling temperature is 920°C, the cooling speed is controlled at 23°C / s, and the final cooling temperature is 295~299°C;

[0035] 5) Natural cooling to room temperature;

[0036] 6) Perform tempering, and the tempering temperature is controlled at 280~290°C.

Embodiment 2

[0038] A kind of NM400 crack-resistant high-strength wear-resistant steel, its components and weight percentage content: C: 0.062%, Si: 0.39%, Mn: 1.42%, Als: 0.023%, P: 0.013%, S: 0.0048%, Cr: 0.45%, Mo: 0.38%, Ti: 0.015%, B: 0.0013%, the rest are Fe and trace impurity elements, and satisfy CEV=C+Mn / 6+(V+Mo+Cr) / 5+ (Ni +Cu) / 15=0.512.

[0039] Production steps:

[0040] 1) Smelting and continuous casting into billets;

[0041] 2) Heating the billet, the heating temperature is controlled at 1180~1187°C;

[0042] 3) Rolling process: start rolling temperature 1090~1100℃, finish rolling temperature 1025~1035℃, pass reduction rate: 15%;

[0043] 4) Carry out water cooling, the starting cooling temperature is 930°C, the cooling speed is controlled at 25°C / s, and the final cooling temperature is 265~275°C;

[0044] 5) Natural cooling to room temperature;

[0045] 6) Perform tempering, and the tempering temperature is controlled at 270~290°C.

Embodiment 3

[0047] A kind of NM400 crack-resistant high-strength wear-resistant steel, its components and weight percentage content: C: 0.072%, Si: 0.33%, Mn: 1.35%, Als: 0.022%, P: 0.011%, S: 0.0022%, Cr: 0.26%, Mo: 0.47%, Ti: 0.021%, B: 0.0023%, the rest are Fe and trace impurity elements, and satisfy CEV=C+Mn / 6+(V+Mo+Cr) / 5+ (Ni +Cu) / 15≤0.57.

[0048] Production steps:

[0049] 1) Smelting and continuous casting into billets;

[0050] 2) Heating the billet, the heating temperature is controlled at 1230~1240°C;

[0051] 3) Rolling process: start rolling temperature 1120~1130℃, finish rolling temperature 1040~1050℃, pass reduction rate: 20%;

[0052] 4) Carry out water cooling, the starting cooling temperature is 940°C, the cooling speed is controlled at 27°C / s, and the final cooling temperature is 275~295°C;

[0053] 5) Natural cooling to room temperature;

[0054] 6) Perform tempering, and the tempering temperature is controlled at 310~320°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness specification | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Rm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com