Pigment color paste for on-line color mixing, surface sizing and coating of culture paper pulp and preparation method thereof

A technology of pigment color paste and surface sizing, applied in the field of color paste, can solve the problems of difficult to meet the needs of paper mills, poor color consistency, poor dilution stability, etc., and achieve the goal of improving product quality, storage stability, and high retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

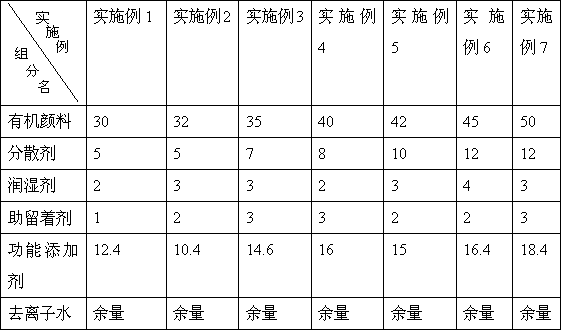

[0023] The formula of the embodiment of the present invention is referring to table 1

[0024] Table 1 (unit: weight percentage)

[0025]

[0026] Remarks: The organic pigment in Example 1 is Pigment Violet 23, the dispersant is alkyl phosphate ester salt and fatty alcohol block copolymer, the wetting agent is isomeric alcohol polyoxyethylene ether, and the retention aid is pigmented The acrylic acid copolymer of affinity group, functional additive adopts propylene glycol, mineral oil defoamer and benzisothiazolinone mildew-proof bactericide; The organic pigment in embodiment 2 adopts pigment violet 23, and dispersant adopts alkyl sulfate salt and fatty alcohol block copolymer, fatty alcohol polyoxyethylene ether is used as wetting agent, modified bisphenol A polyoxyethylene ether phosphate salt is used as retention agent, propylene glycol, mineral oil defoamer and carbamide are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com