Micro-cantilever beam array biochemical sensing apparatus and biochemical detection method thereof

A technology of micro-cantilever beam and sensing device, which is applied in the field of biochemical sensing, can solve the problems affecting the consistency of the laser beam emitted by the optical fiber array and the effective detection distance, affecting the quality of spot displacement detection, and low detection sensitivity, so as to improve biochemical detection. The effect of precision, light weight and high scanning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

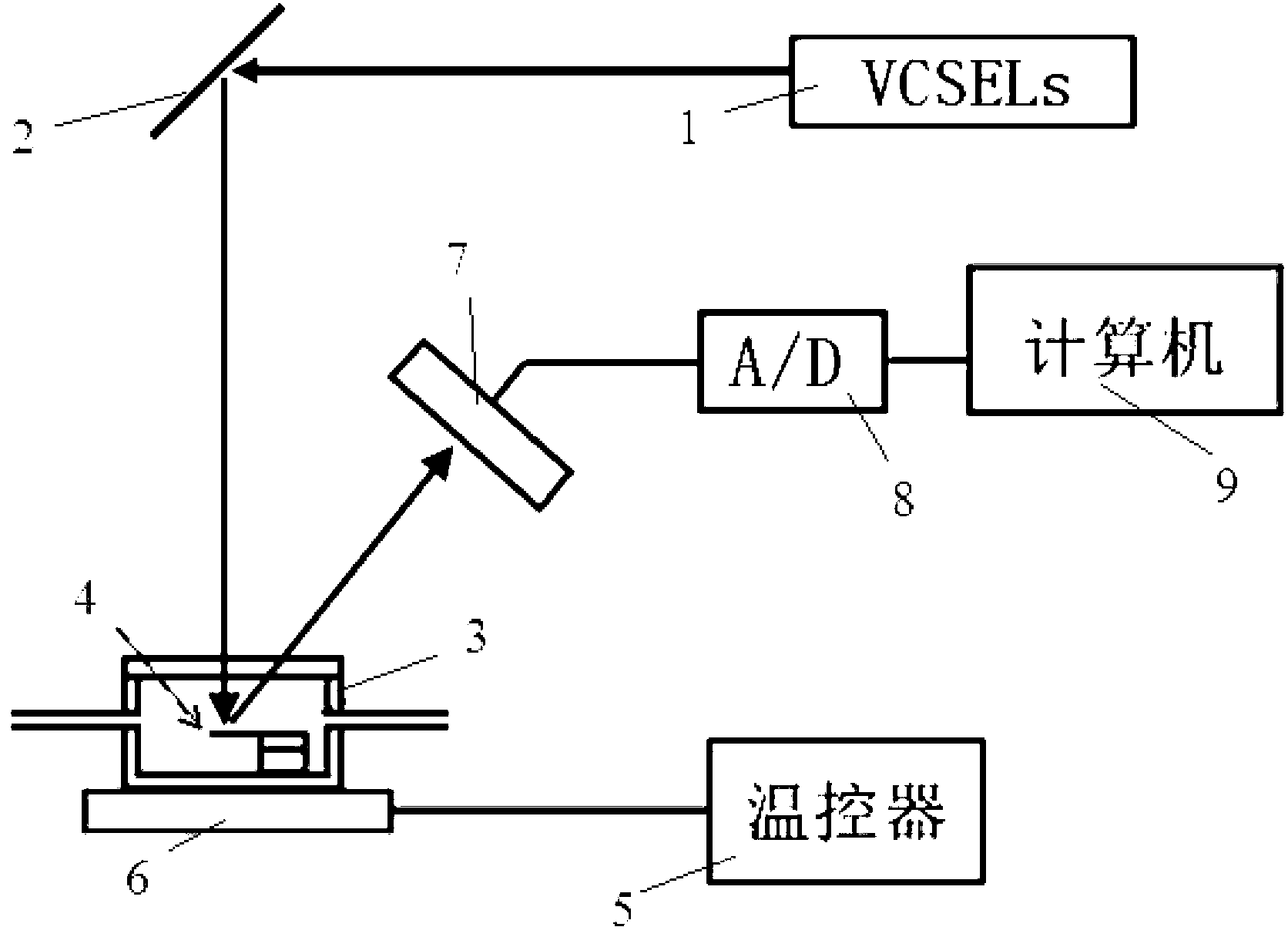

[0082] Example 1. Measurement of temperature changes by a micro-cantilever array sensing method based on a vertical cavity surface emitting laser array

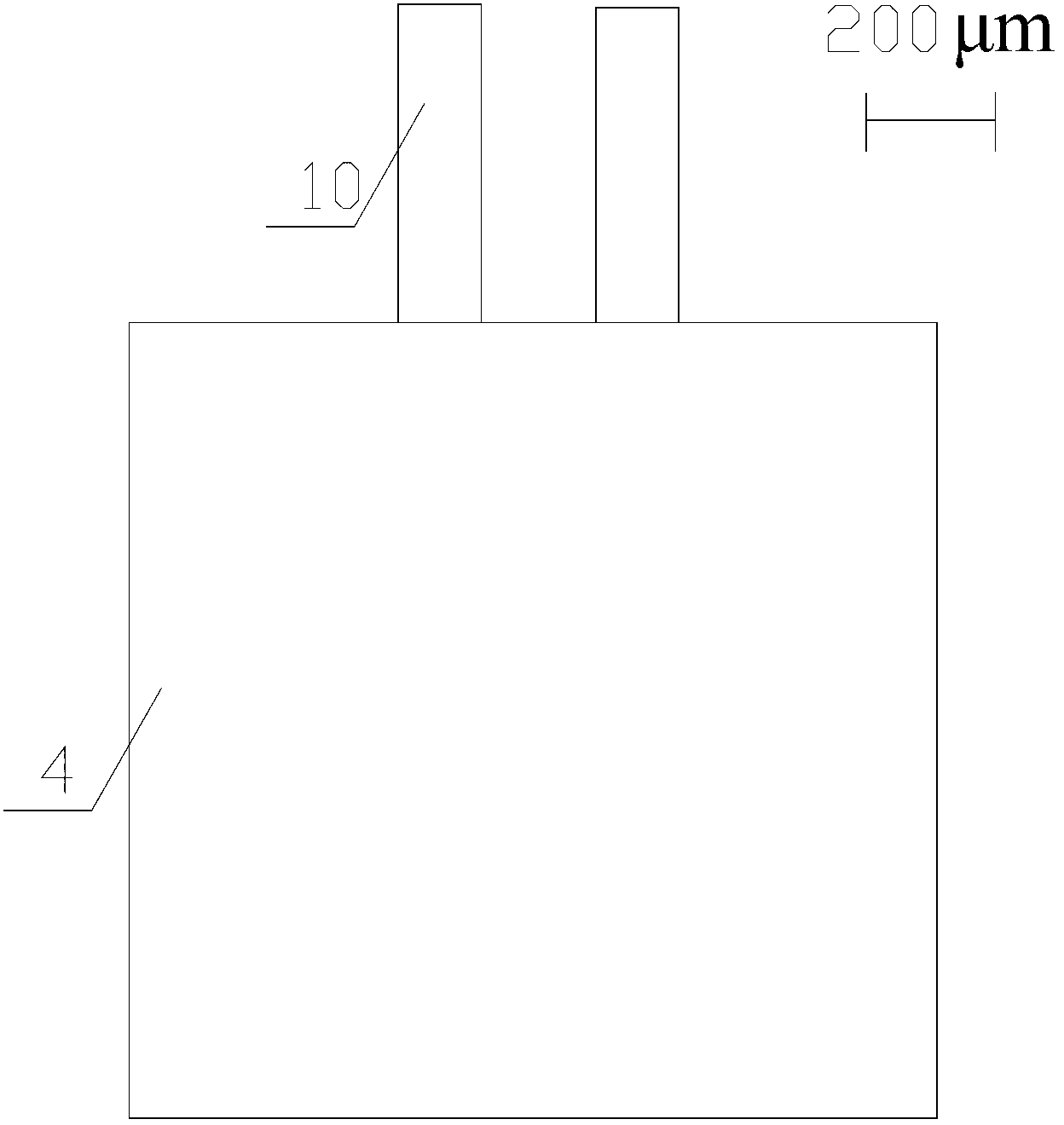

[0083] 1. A commercial microcantilever array (German micromotive company, such as image 3 As shown, the microcantilever beam is 500 μm long, 90 μm wide, and 1 μm thick, the surface is coated with a 0.02 μm thick gold layer, and the center-to-center distance between two microcantilever beams is 250 μm) fixed to the system (including VCSELs, Biochemical reaction pool, temperature controller, PSD, A / D converter, computer, such as figure 1 Shown) in the biochemical reaction pool.

[0084] 2. The laser beam emitted by the vertical cavity surface emitting laser array periodically scans two fixed points with a distance of 250 μm on the substrate of the microcantilever array for 9 hours, and the scanning displacement curve is shown in Figure 4a and Figure 4b As shown: In the X direction and Y direction, the two scanning positio...

Embodiment 2

[0086] Example 2. Detection of Clenbuterol by Microcantilever Array Biochemical Sensing Method Based on Vertical Cavity Surface Emitting Laser Array

[0087] 1. Experimental Setup and Reagents

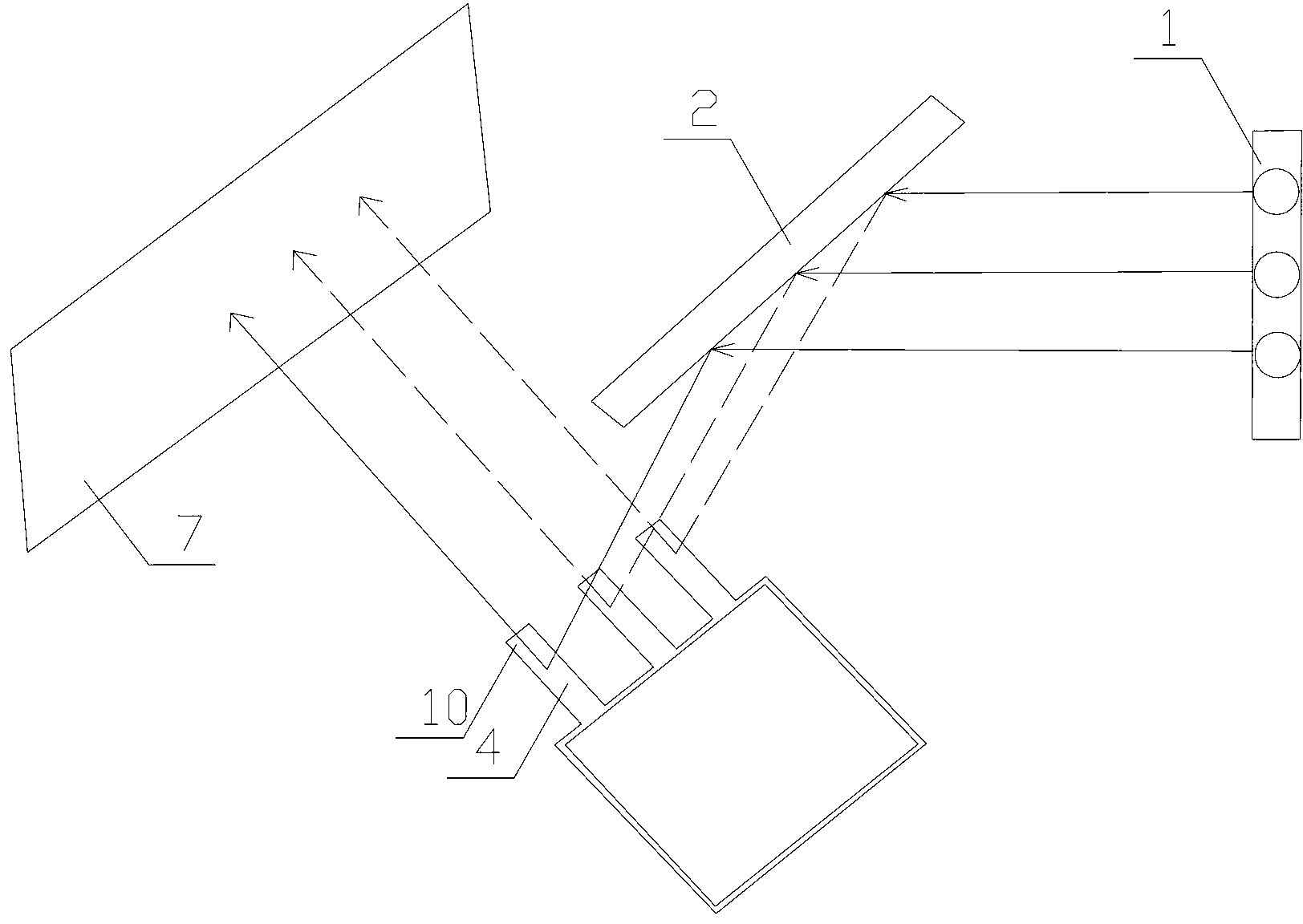

[0088] The specific structure of the detection system is as follows: figure 1 As shown in , it mainly includes vertical cavity surface emitting laser array (parameters: 2 arrays, height 160μm, width 250μm, total length 500μm, distance between adjacent laser centers 250μm, maximum input voltage 5V, wavelength of emitted laser is 650nm), biochemical reaction pool (volume 0.5mL, fully sealed, mainly composed of a sample inlet 11 with an inner diameter of 1mm, a sample outlet 12, a glass slide 13, and a micro-cantilever beam array fixed platform 14, Figure 7 ), temperature controller (temperature control accuracy 0.01℃, temperature control range 0℃~100℃), PSD (displacement resolution 1μm, target surface size 22mm×22mm), A / D converter (16 bits), computer.

[0089] Clenbuterol antibody, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com