Variable-cycle multi-beam interference photoetching method

A multi-beam interference and lithography technology, which is applied in the field of nano-processing, can solve problems such as complex optical paths and difficult adjustment of beam incident angles, and achieve the effect of simple optical paths, easy pattern cycles, and large-area multi-beam interference lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

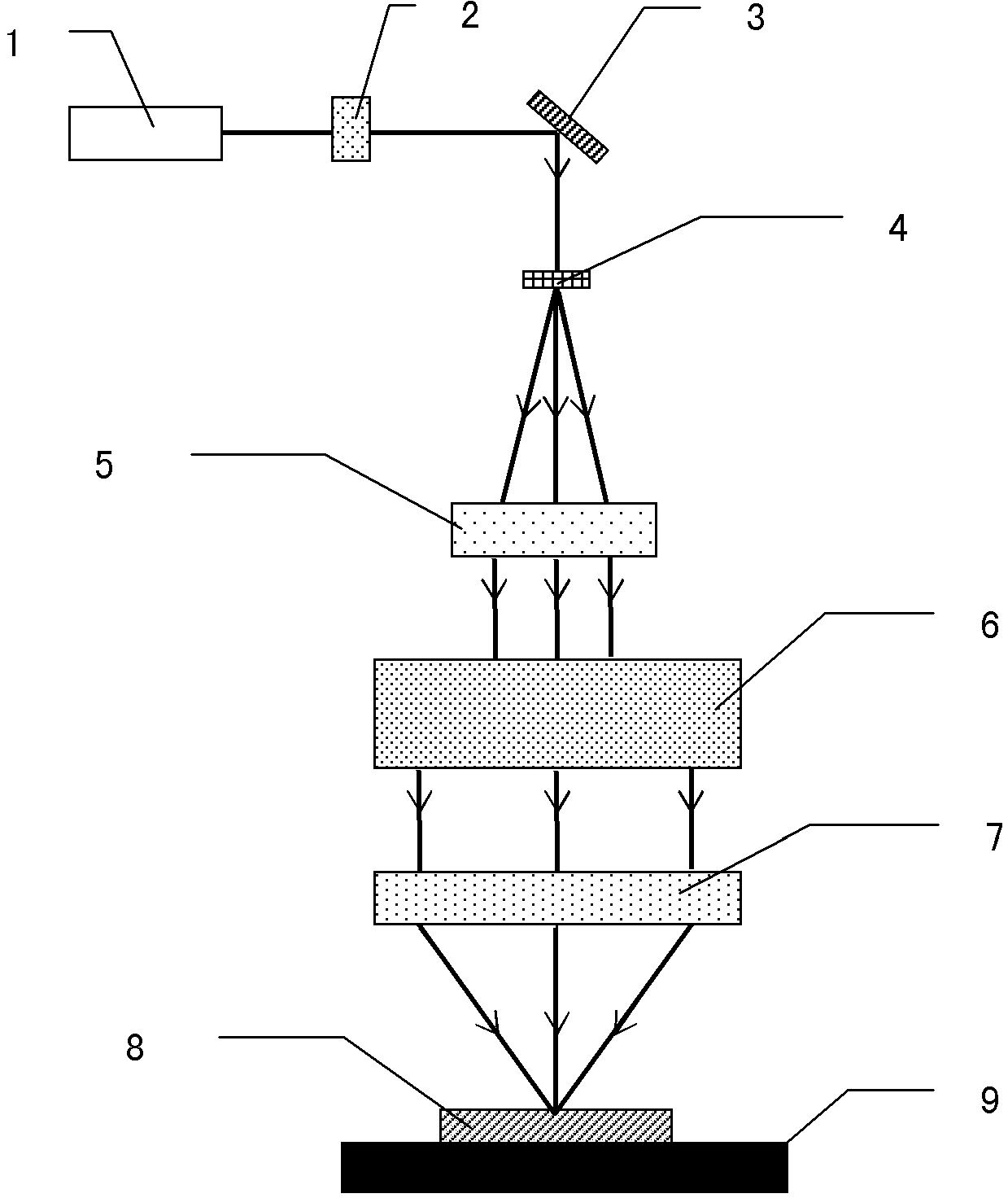

[0040] Embodiment 2 of the present invention is a four-beam interference lithography system capable of adjusting the period in the range of 656 nm to 1.94 μm.

[0041]In this system, the ultraviolet laser 1 is an argon ion laser with an output wavelength of 363.8nm, and the light splitting element 4 is a four-beam light splitting element, which is a phase diffractive optical element, and the first-order light diffraction angle is 10°. With regard to the rotational symmetry of the optical axis, the focal length of the collimator lens 5 is 25 mm, and the aperture is 12.5 mm. The incident aperture of the continuous zoom beam expander 6 is 10 mm, and the output aperture is 30 mm. times, the focal length of the focusing lens 7 is 50 mm, the aperture is 30 mm, and the numerical aperture is 0.3.

[0042] Place the light splitting element 4 at the focal point of the collimating lens 5, the laser beam is symmetrically divided into four beams by the light splitting element 4 after shapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com