Solid oxide fuel cell system and thermoelectricity synergic control method

A fuel cell system and solid oxide technology, which is applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of high exhaust gas temperature, limited adjustable flow, not considering SOFC system, etc., to improve the system. Efficiency and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

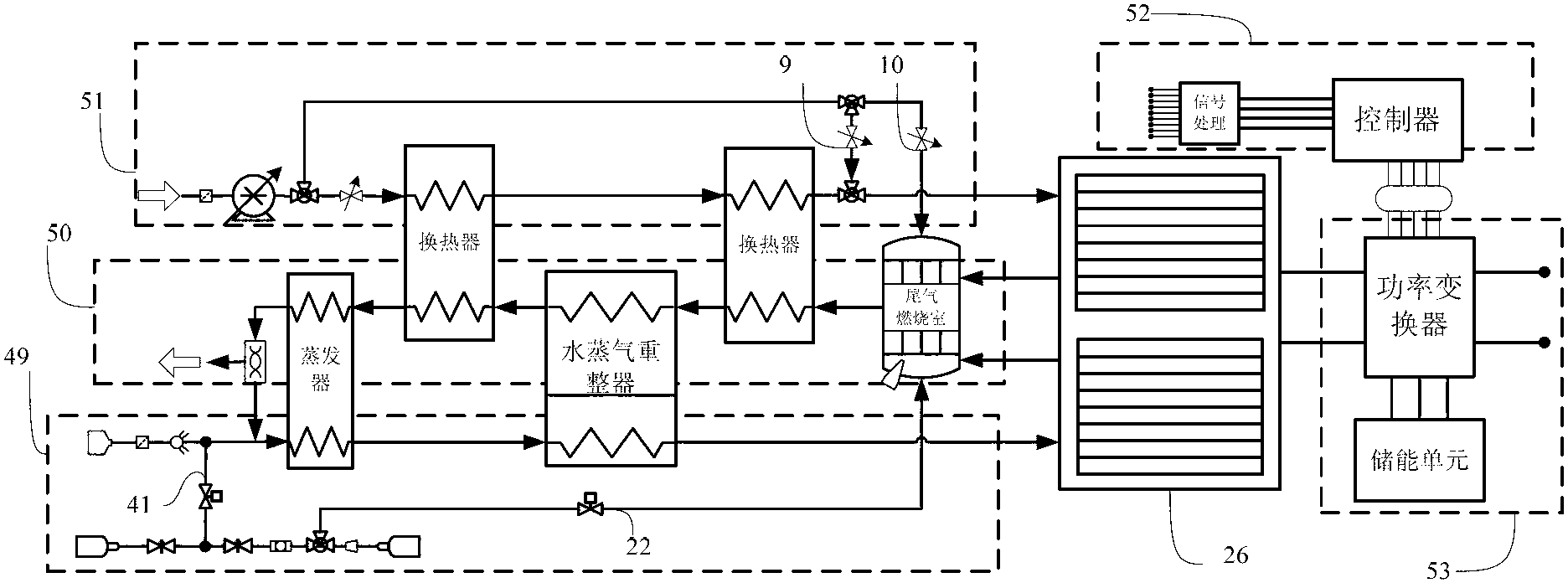

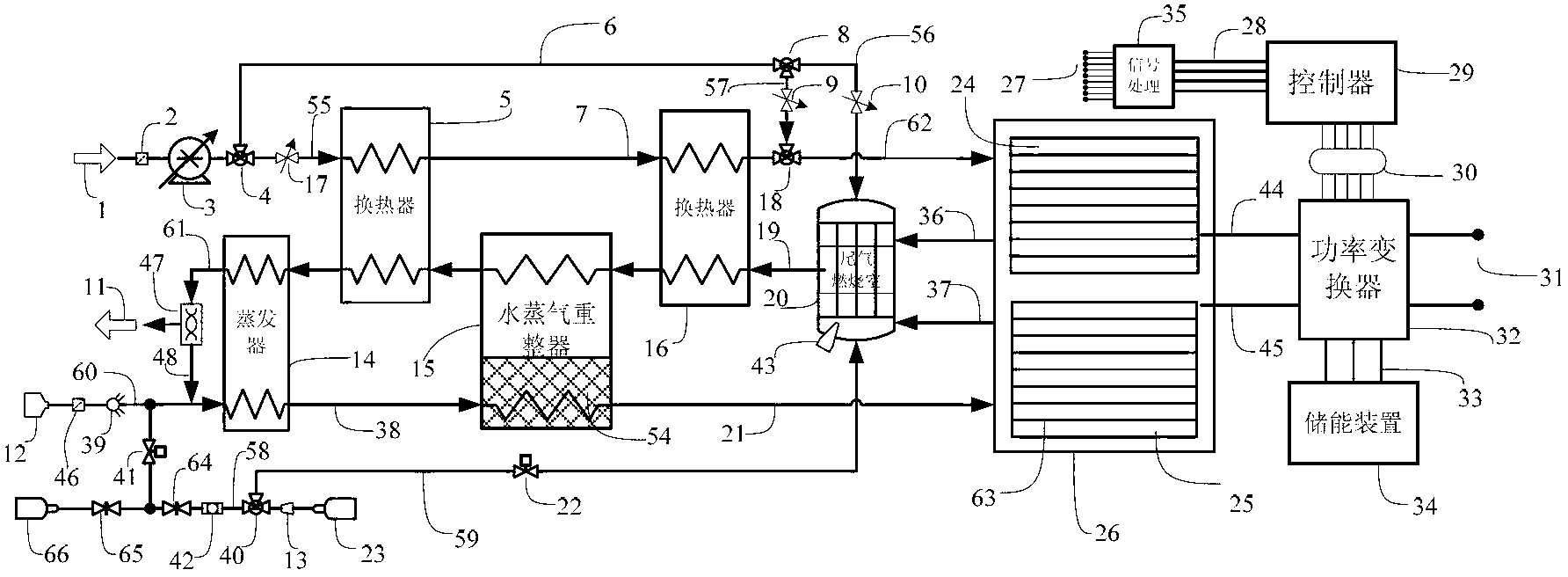

[0034] like figure 1 As shown, the system includes: stack unit 26, air supply unit 51, fuel supply unit 49, exhaust gas recovery unit 50, electrical management unit 52, control unit 53, first valve 9, second valve 10, first mass flow meter 22 and the second mass flow meter 41. The first output end of the air supply unit 51 is connected to the cathode gas input end of the stack unit 26 through the first valve 9 pipeline, and the second output end of the air supply unit 51 is connected to the air input end of the tail gas recovery unit 50 through the second valve 10 pipeline The hydrogen output end of the fuel supply unit 49 is connected to the anode gas input end of the stack unit 26 by the second mass flow meter 41 pipelines, and the fuel output end of the fuel supply unit 49 is connected to the tail gas recovery unit 50 by the first mass flow meter 22 pipelines Fuel input end; the exhaust gas output end of the electric stack unit 26 is connected to the input end of the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com