Core-shell structured silica @ mesoporous silica supported gold nanoparticle microbead and preparation method of same

A technology of mesoporous silica and gold nanoparticles, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of poor quality of Raman spectra of metal nanostructures, achieve controllable size and shape, and enhance Raman spectra , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

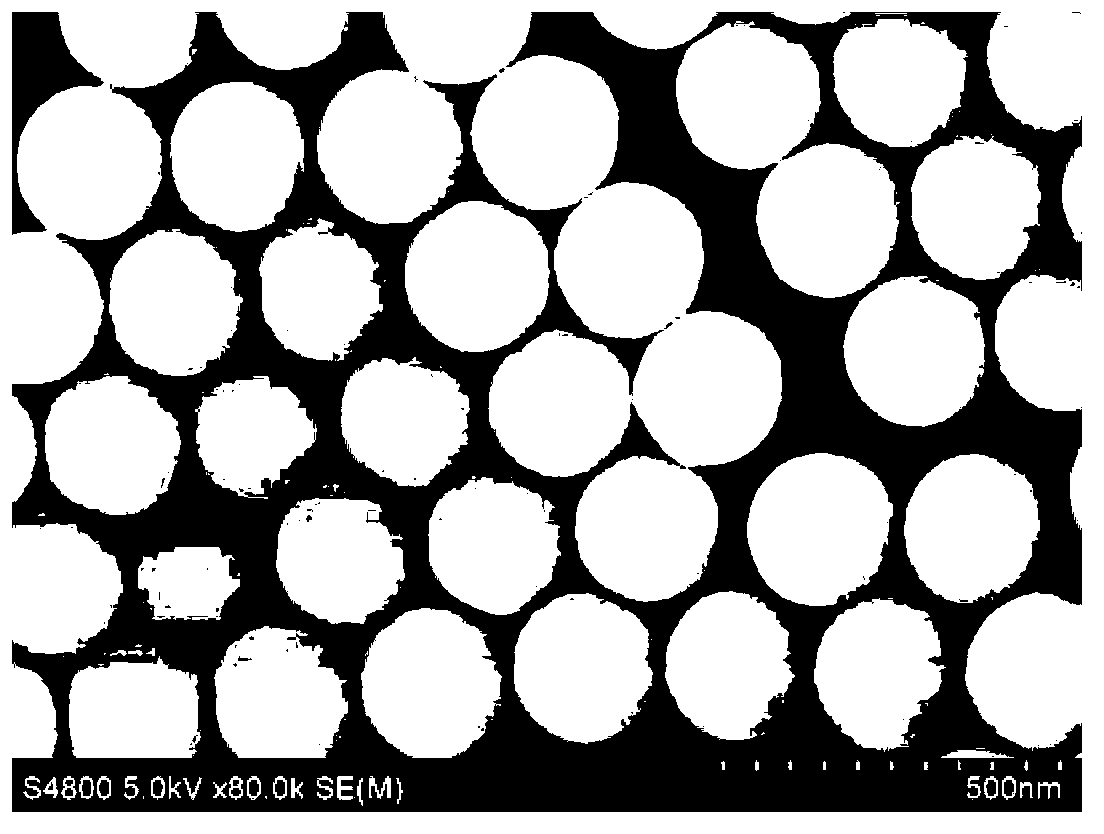

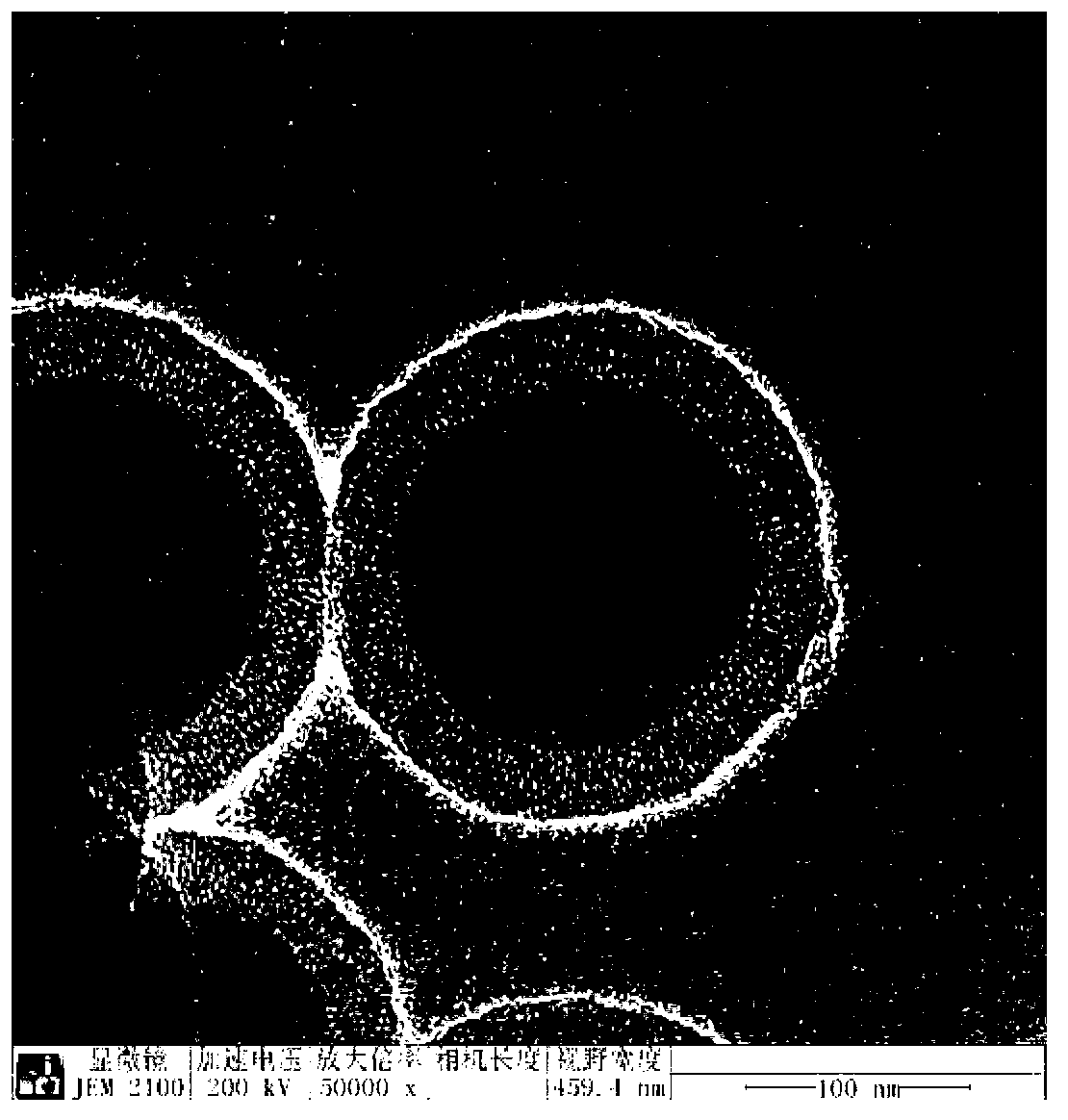

[0035] Specific embodiment one: In this embodiment, the core-shell structure silica mesoporous silica-supported gold nanoparticle microbeads are composed of a core layer and a shell layer, and the core layer is silica spherical nanoparticles; the shell layer It consists of mesoporous silica and gold nanoparticles, and the gold nanoparticles are adsorbed in the mesopores of mesoporous silica.

specific Embodiment approach 2

[0036] Embodiment 2: Embodiment 1 The preparation method of the core-shell structure silica mesoporous silica supporting gold nanoparticle microbeads is as follows:

[0037] 1. Preparation of silica nanoparticles:

[0038] Stir and mix 150-160mL absolute ethanol and 32-38mL ammonia water with a mass concentration of 30% at a speed of 190-210rpm, raise the temperature to 60°C at a rate of 5-10°C / min, and then add 2.2mL of For tetraethyl silicate, keep the temperature of 60°C and the rotation speed of 190-210rpm to continue the reaction for 24h to obtain small silica nanoparticles;

[0039] Two, preparation of silica nano-seeds:

[0040] Stir and mix 150-160mL absolute ethanol and 12-18mL concentrated ammonia water with a mass concentration of 30% at a speed of 200rpm, and add the silicon dioxide obtained in step 1 dropwise in a constant temperature water bath at 25°C with a stirring speed of 200rpm. Nano small particles, react for 15min, then add tetraethyl orthosilicate etha...

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, 160mL of absolute ethanol and 36mL of ammonia water with a mass concentration of 30% are stirred and mixed evenly at a speed of 200rpm. The heating rate of °C / min was increased to 60 °C, and then 2.2 mL of tetraethyl orthosilicate was added, and the temperature was maintained at 60 °C and the rotation speed was 200 rpm to continue the reaction for 24 hours to obtain small silica nanoparticles. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com