Iron and nitrogen co-doping titanium dioxide/active carbon photocatalyst

A titanium dioxide and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical/physical processes, chemical instruments and methods, etc., can solve the problem of high recombination rate of photogenerated electrons and holes, increased energy consumption and operating costs, and low catalytic efficiency to achieve high pollutant removal efficiency and reuse rate, which is beneficial to adsorption performance and simplifies the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

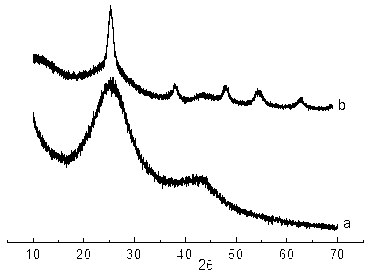

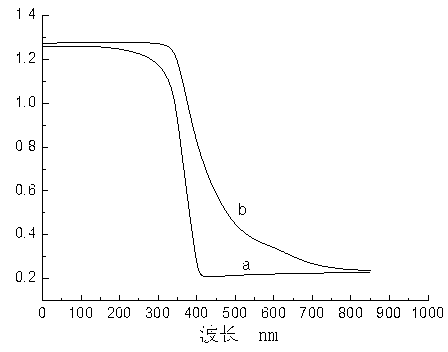

Image

Examples

preparation example Construction

[0024] A preparation method of iron, nitrogen co-doped titanium dioxide / activated carbon photocatalyst, the method specifically comprises the following steps:

[0025] (1) Mixing of raw materials: (a) Mix the carbon source material and titanium dioxide at a mass ratio of 1:0.01 to 0.3, and stir evenly to form a mixture; (b) Mix the solution of ferric nitrate and pure additives at a mass ratio of 1 to 15 : 100 for mixing and dissolving to form a mixed liquid; (c) Mix the above-mentioned mixture and the mixed liquid (based on the mass of the pure additive) at a mass ratio of 1:0.75-2.5, stir evenly, and immerse at room temperature for 0.5-12 hours.

[0026] (2) Forming: Knead the above impregnated raw materials at 100-250°C for 10-120 minutes, and after the raw materials are in a loose state, carry out extrusion molding.

[0027] (3) Hardening: harden the above-mentioned molding raw materials at 100-250°C for 1-6 hours.

[0028] (4) Activation roasting: Activate the above-menti...

Embodiment 1

[0031] A preparation method of iron, nitrogen co-doped titanium dioxide / activated carbon photocatalyst, the method specifically comprises the following steps:

[0032] (1) Mixing of raw materials: (a) Mix fir chips with a water content of 10% and titanium dioxide at a mass ratio of 1:0.1, and stir evenly to form a mixture; (b) Ferric nitrate and 50% phosphoric acid solution are mixed at a mass ratio of Mix and dissolve at a ratio of 1:10 to form a mixed solution; (c) Mix the above-mentioned mixture and the mixed solution (based on the mass of pure phosphoric acid) at a mass ratio of 1:1.5, stir evenly, and immerse at room temperature for 6 hours.

[0033] (2) Forming: Put the impregnated raw materials above in a kneader and knead them at 140°C for 50 minutes. After the raw materials are in a loose state, place them in a twin-screw extruder for extrusion molding.

[0034] (3) Hardening: Put the above-mentioned molding raw materials in a tunnel drying kiln for hardening at 140°C f...

Embodiment 2

[0038] A preparation method of iron, nitrogen co-doped titanium dioxide / activated carbon photocatalyst, the method specifically comprises the following steps:

[0039] (1) Mixing of raw materials: (a) mix bamboo chips with a water content of 8% and titanium dioxide at a mass ratio of 1:0.15, and stir evenly to form a mixture; (b) mix ferric nitrate with a 60% solution at a mass ratio of 1 :20 for mixing and dissolving to form a mixed solution; (c) Mix the above-mentioned mixture and the mixed solution (based on the mass of pure phosphoric acid) at a mass ratio of 1:1.25, stir evenly, and immerse at room temperature for 8 hours.

[0040] (2) Forming: Put the impregnated raw materials above in a kneader and knead for 40 minutes at 150°C. After the raw materials are in a loose state, place them in a twin-screw extruder for extrusion molding.

[0041] (3) Hardening: Put the above-mentioned molding raw materials in a tunnel drying kiln for hardening at 150°C for 2 hours.

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com