Method for preparing metal core for investment casting and precision investment casting method for aluminum alloy casting based on metal core

A technology of investment precision casting and aluminum alloy castings, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of small gaps and high requirements on the surface quality of gaps, and achieve the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a metal core for investment casting, comprising the following steps:

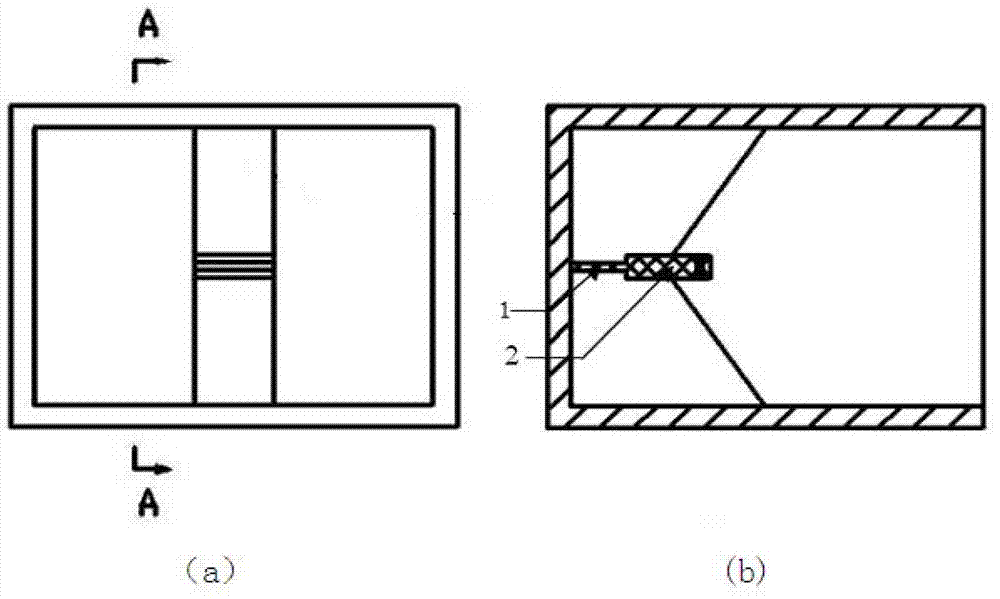

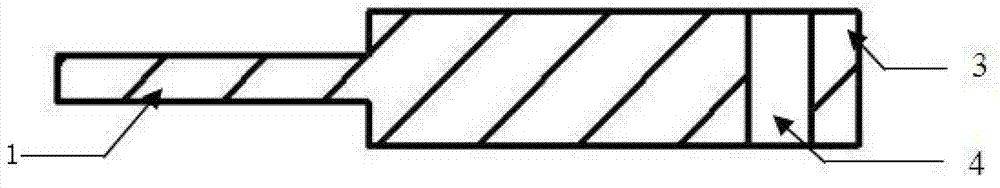

[0024] Metal Core and Forming: see figure 1 and 2 , design a metal core 2 with a width of 0.50mm, leave a 7mm core 3 at one end and reserve a hole 4 on the core 3 for taking out the metal core, and the other end is a forming part 5, and then use slow wire cutting The method is to process the nickel-based or iron-based superalloy into a designed metal core 2 and grind and polish the surface of the metal core 2 so that the dimensional accuracy is ±0.04mm.

[0025] An investment casting method for aluminum alloy castings based on a metal core, comprising the following steps:

[0026] 1) Formwork production: mix water glass, boric acid and titanium oxide according to the mass percentage of 5:25:70 to prepare titanium oxide coating, dissolve and dilute the titanium oxide coating with hot water to a concentration of 1.2g / cm 3 , the metal core 2 was heated to 150°C, and the surface...

Embodiment 2

[0031] A method for preparing a metal core for investment casting, comprising the following steps:

[0032] Metal core and forming: Design a metal core 2 with a width of 0.70mm, leave a 7mm core 3 at one end and reserve a hole 4 on the core 3 for taking out the metal core, and the other end is a forming part 5, and then use The method of slow wire cutting processes the nickel-based or iron-based superalloy into a designed metal core 2 and grinds and polishes the surface of the metal core 2 so that the dimensional accuracy is ±0.04mm.

[0033] An investment casting method for aluminum alloy castings based on a metal core, comprising the following steps:

[0034] 1) Form shell production: mix water glass, boric acid and titanium oxide according to the mass percentage of 3:29:68 to prepare titanium oxide coating, dissolve and dilute the titanium oxide coating with hot water to a concentration of 1.2g / cm 3 , the metal core 2 was heated to 100°C, and the surface of the metal core ...

Embodiment 3

[0039] A method for preparing a metal core for investment casting, comprising the following steps:

[0040] 1) Metal core and molding: design a metal core 2 with a width of 0.6mm, leave a 7mm core head 3 at one end and reserve a hole 4 on the core head 3 for taking out the metal core, and the other end is a forming part 5, Then, the nickel-based or iron-based superalloy is processed into the designed metal core 2 by slow wire cutting, and the surface of the metal core 2 is ground and polished so that the dimensional accuracy is ±0.04mm.

[0041] An investment casting method for aluminum alloy castings based on a metal core, comprising the following steps:

[0042] 1) Formwork production: mix water glass, boric acid and titanium oxide according to the mass percentage of 7:21:72 to prepare titanium oxide coating. Use hot water to dissolve and dilute the titanium oxide coating to a concentration of 1.2g / cm 3 , the metal core 2 was heated to 200°C, and the surface of the metal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com