High-abrasion soles and sole material and preparation method of sole material

A shoe sole material and high wear-resistant technology, which is applied in the field of shoe soles and shoe sole materials, can solve the problems of non-wear resistance, and achieve the effect of good shoe material quality, high density, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a preferred embodiment of the high wear-resistant shoe sole and shoe sole material of the present invention, its components and parts by weight are as follows: 80 parts of styrene-butadiene block copolymer, 15 parts of polystyrene, butadiene rubber 10 parts, 15 parts naphthenic oil, 2 parts azodicarbonyl, 2 parts zinc stearate, 2 parts zinc oxide.

[0024] The materials are weighed according to the above proportions, manufactured and processed according to the above process, and molded under the condition of 150°C. The sample was placed at room temperature of 25°C for more than 24h to test its hardness of 59 and relative density of 1.19g / cm 3 ; According to QB / T2884-2007 standard test DIM wear is 246mm 3 .

Embodiment 2

[0026] The components and parts by weight are as follows: 85 parts of styrene-butadiene block copolymer, 15 parts of polystyrene, 5 parts of cis-butadiene rubber, 15 parts of naphthenic oil, 1.2 parts of azodicarbonamide, stearic acid 0.8 parts of zinc, 1.5 parts of zinc oxide.

[0027] Add 3 parts dye, and 5 parts filler. The softness, elasticity, hardness and specific gravity of the shoe material are maintained, and the wear resistance of the shoe material is improved to the greatest extent.

[0028] The materials are weighed according to the above proportions, manufactured and processed according to the above process, and molded under the condition of 150°C. The sample was placed at room temperature of 25°C for more than 24h to test its hardness of 100 and relative density of 1.15g / cm 3 ;according to

[0029] QB / T2884-2007 standard test DIM wear is 52mm 3 .

Embodiment 3

[0031] The components and parts by weight are as follows: 100 parts of styrene-butadiene block copolymer, 15 parts of polystyrene, 5 parts of cis-butadiene rubber, 15 parts of naphthenic oil, 1.2 parts of azodicarbonamide, stearic acid 0.8 parts of zinc, 1.2 parts of zinc oxide.

[0032] In the preferred embodiment of the present invention, 3 parts of dyeing agent and 5 parts of filler are also added. The softness, elasticity, hardness and specific gravity of the shoe material are maintained, and the wear resistance of the shoe material is improved to the greatest extent.

[0033] The materials are weighed according to the above proportions, manufactured and processed according to the above process, and molded under the condition of 150°C. The sample was placed at room temperature of 25°C for more than 24 hours to test its hardness of 63 and relative density of 1.17g / cm 3 ; According to QB / T2884-2007 standard test DIM wear is 273mm 3 .

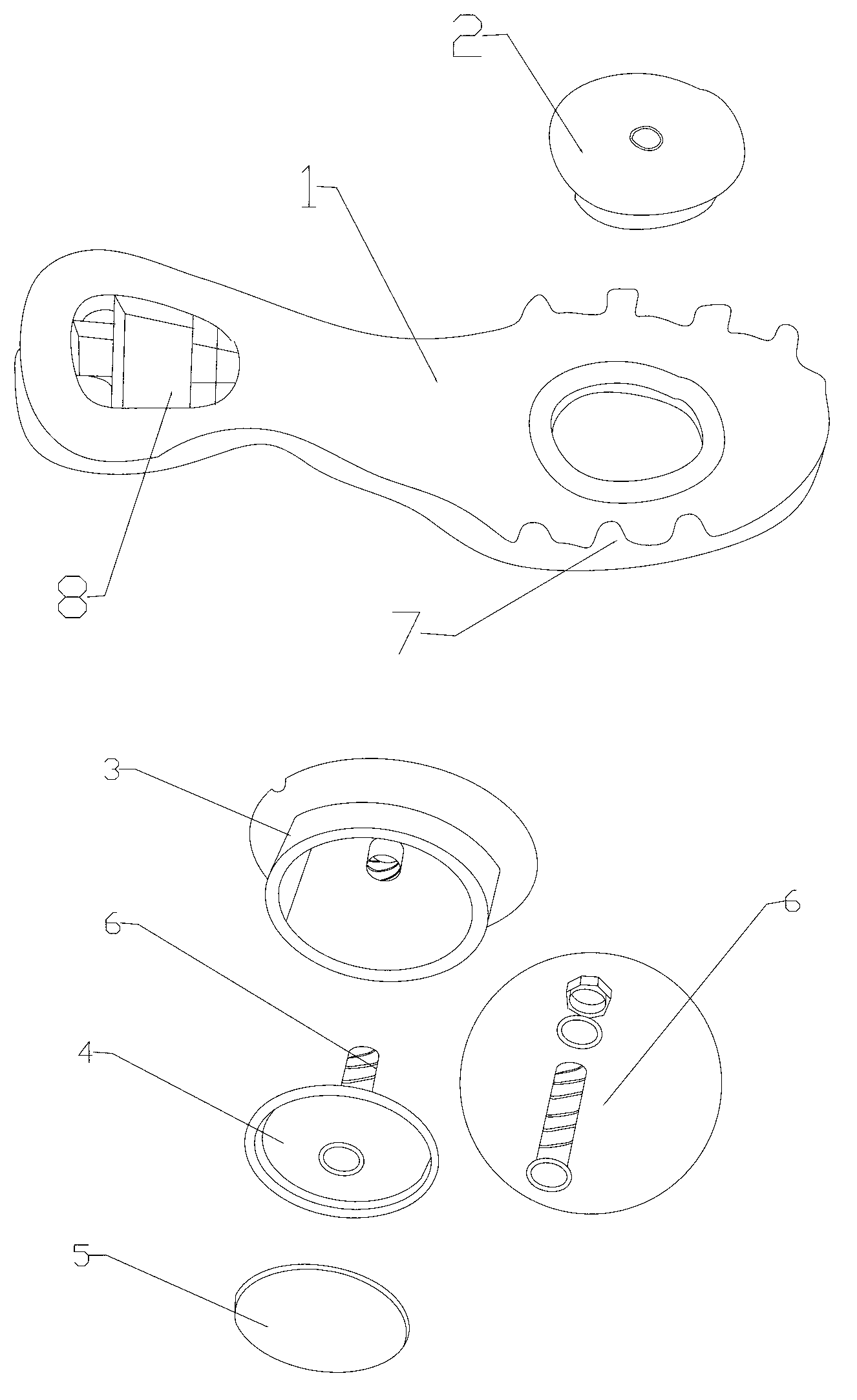

[0034] refer to figure 1 , a sport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com