Conical-face welding type hydrogen sulfide corrosion-resistant boring rod adopting same material and processing process thereof

A technology of the same material and anti-hydrogen sulfide, which is applied in the field of drill pipes, can solve problems such as the failure of anti-sulfur drill pipe welds and the reduction of the apparent diffusion coefficient of hydrogen atoms, so as to improve the anti-sulfide stress corrosion cracking performance and ensure the performance , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

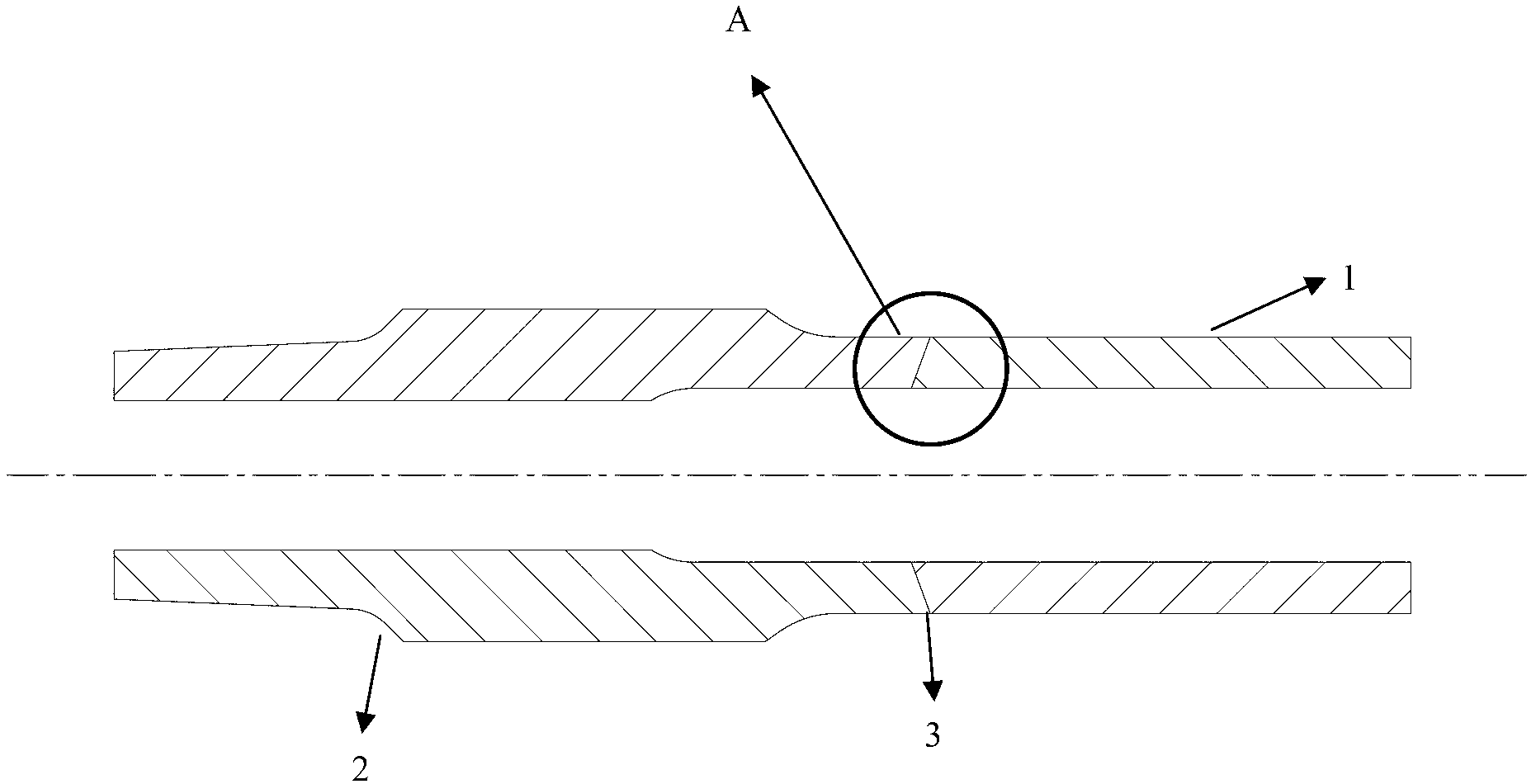

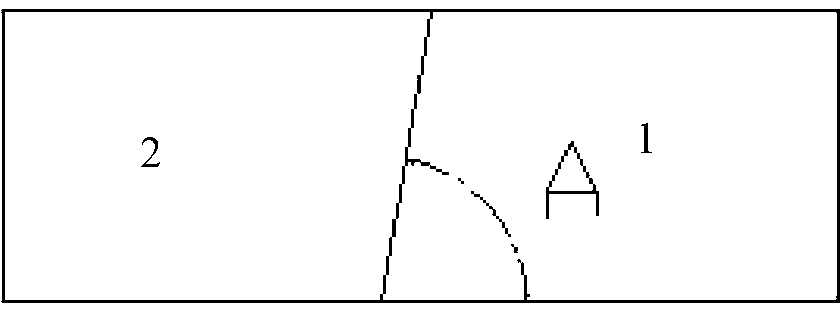

[0039] The invention discloses a friction-welded anti-hydrogen sulfide corrosion drill pipe using the same material, the structure of which is as follows: figure 1 , 2 As shown: the drill pipe body 1 and the joint 2 are made of the same material, and the chemical composition of the material is composed of the following weight percentages: C0.22%~0.34%, Mn0.6%~1.1%, P≤0.010%, S≤0.005%, Cr0.6%~1.2%, Mo0.5%~1.2%, Si0.17~0.35%, V0.10~0.30%, Nb0.01~0.06%, Ca0.005~0.03%, Al ≤0.030%, the rest is Fe and non-removable trace elements.

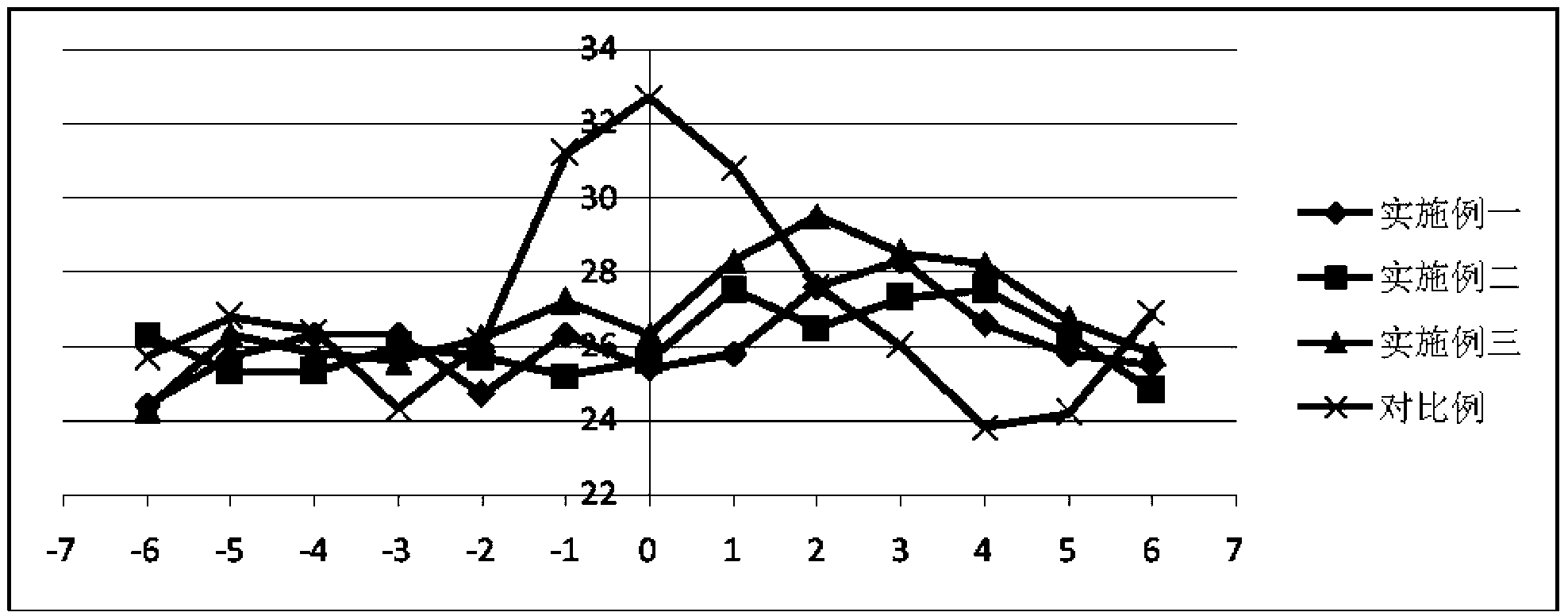

[0040]Below in conjunction with embodiment one, two, three that the present invention requires and conventional anti-sulfur drill pipe weld performance as a contrast (the chemical composition of this case implementation case one, two, three and comparative example is shown in Table 1, wherein, comparative example The drill pipe weld zone uses conventional CrMnMo steel grades of different materials).

[0041] Friction welding and weld seam heat treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com