Method and equipment for recovering heavy metal in electroplating wastewater

A technology for electroplating wastewater and heavy metals, applied in metallurgical wastewater treatment, chemical instruments and methods, electrolysis process, etc., can solve the problems of staying in the laboratory stage or small test, pilot test stage, waste, not easy to form pieces, etc., to achieve reduction Concentration polarization, reduction of investment and management, and effect of effluent water quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

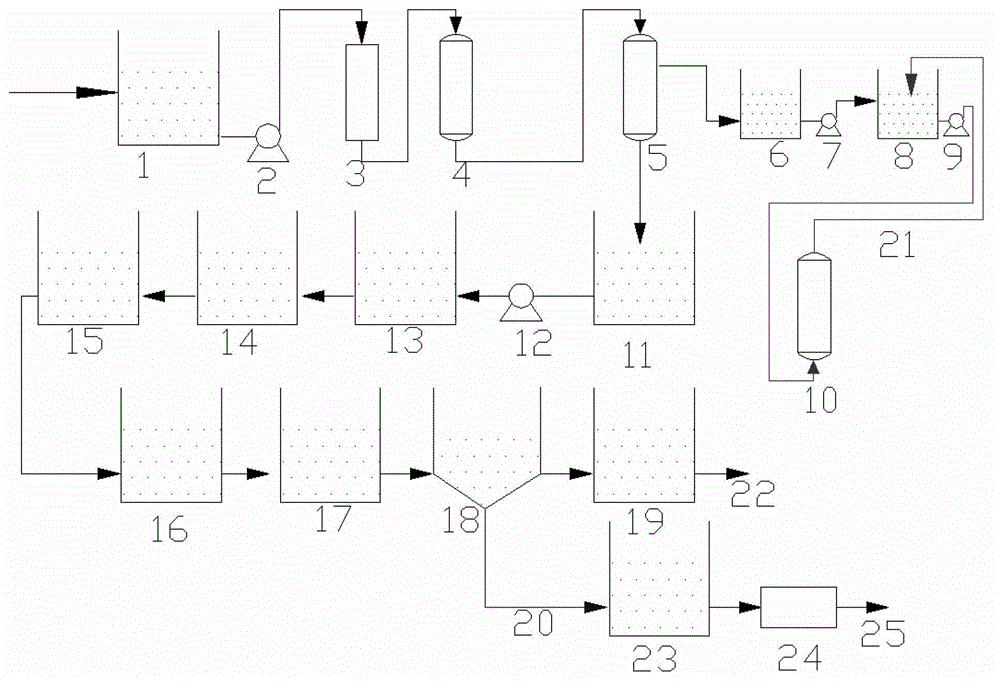

[0032] Such as figure 1 As shown, a device for recovering heavy metals in electroplating wastewater includes a resin exchange treatment unit and an electrolytic recovery treatment unit connected in sequence through pipelines, and a physical and chemical treatment unit connected to the resin exchange treatment unit through pipelines, and the pipeline is connected in series. Lift pumps to facilitate the flow of waste water.

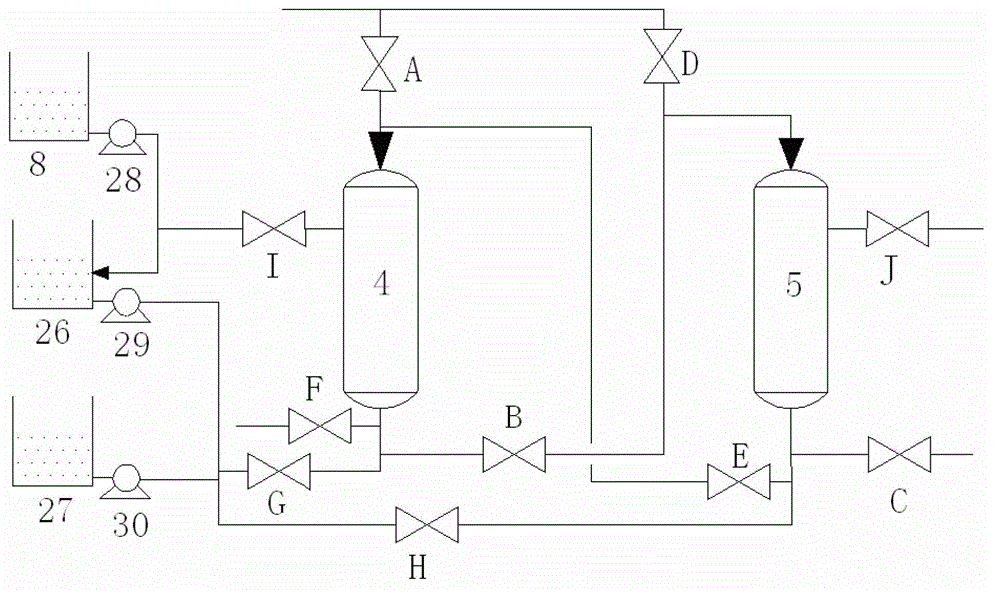

[0033] The resin exchange treatment unit includes a waste water sump 1, a waste water lift pump 2, a guard column 3, two ion exchange resin columns A4 and B5 connected in a switching manner, and a regeneration device connected in sequence. The water outlet end of the ion exchange resin column is also provided with a resin catcher, a conductivity meter and a pH meter. Such as figure 2 As shown, between the water outlet end of the ion exchange resin column A4 and the water inlet end of the ion exchange resin column B5, and between the water outlet end of t...

Embodiment 2

[0037] The method of reclaiming the heavy metals in the electroplating wastewater by the equipment of the recovery electroplating wastewater of embodiment 1 is as follows:

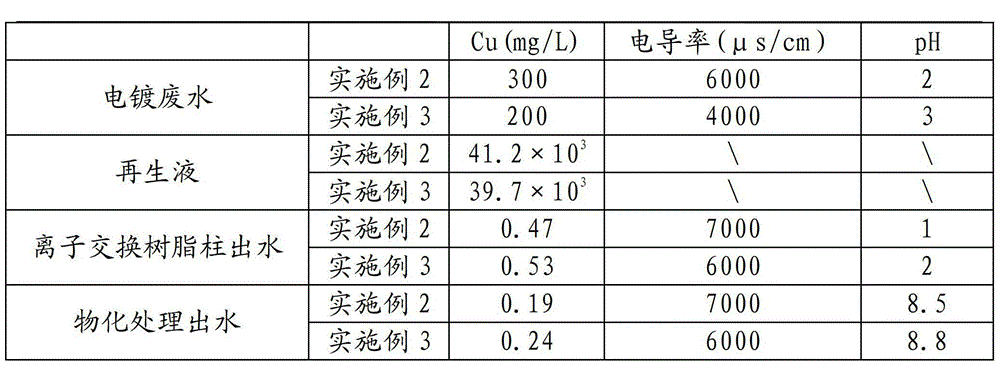

[0038] First, the electroplating industrial acid copper wastewater with a copper ion concentration of 200-300 mg / L enters the wastewater collection tank 1 and stays there for 6 hours, which can stabilize the water quality. The protective column 3 is equipped with an inert resin (plastic floating ball), which is used to intercept suspended matter and part of the colloidal matter in the waste water. The purpose is to reduce the suspended matter from entering the ion exchange resin column and improve the operation stability of the ion exchange resin column. Then enter the series ion exchange resin column A4 and ion exchange resin column B5. The ion exchange resin column adopts the Ambersep M64 resin developed by Dow that has special adsorption for copper. The exchange column tank is 3000mm in diameter and 4000...

Embodiment 3

[0043] Adopt the method that the heavy metal in the recovery electroplating waste water of embodiment 1 carries out the method for reclaiming heavy metal in the electroplating waste water, differs from embodiment 2 in that:

[0044] (1) When the ion exchange resin column is regenerated, 10% sulfuric acid is used to regenerate in the countercurrent middle row.

[0045] (2) During swirl electrolysis, the control flow is 0.6m / s, the voltage is 4V, and the current density is 200A / M 2 , electrolysis at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com