Novel method for preparing fluorine-containing nano-hydroxyapatite coating on surface of biomedical magnesium alloy

A nano-hydroxyapatite, biomedical technology, applied in coatings, pharmaceutical formulations, electrolytic coatings, etc., to achieve the effects of uniform coating morphology, easy control and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

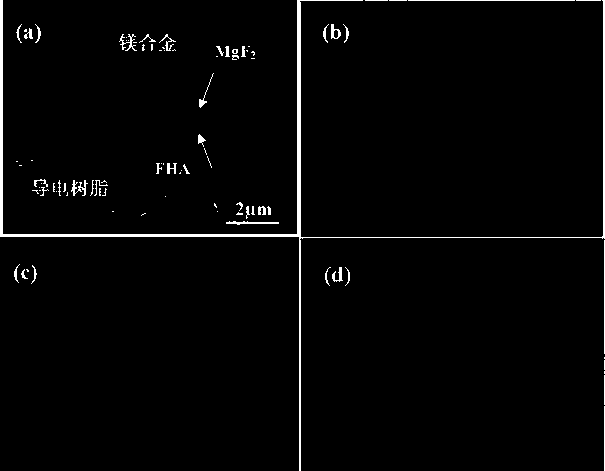

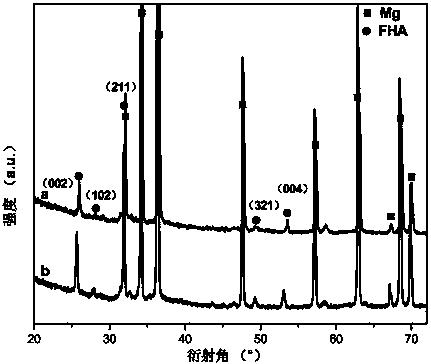

[0032] A fluorine-containing nano-hydroxyapatite coating was prepared on the surface of a Mg-2.02wt%Zn-0.80wt%Ca alloy by a double-pulse electrodeposition method, and the preparation steps were as follows:

[0033] (1) Substrate material preparation: cutting the magnesium alloy wire 12mm×4mm cylinder, use 240 # 、400 # 、600 # , 800 # 、1000 # The surface of the SiC water abrasive paper was polished in turn, rinsed with deionized water, and then ultrasonically cleaned with an acetone / absolute ethanol mixed solution with a volume ratio of 1:1 at room temperature for 5 minutes to remove surface oil stains, and the base material was taken out and air-dried for later use ;

[0034] (2) Put the cleaned substrate material in a plastic beaker for fluorination treatment, the concentration of hydrofluoric acid is 40wt%, and the fluorination treatment time is 20 hours. After cleaning the substrate material that has undergone fluorination treatment with deionized water dry;

[0035]...

Embodiment 2

[0049] Taking AZ31 as the base material, the preparation steps are as follows:

[0050] (1) Substrate material preparation: cutting the magnesium alloy wire 12mm×5mm cylinder, use 240 # 、400 # , 800 # 、1000 # The surface of the alloy was polished with SiC water-grinding paper in turn, rinsed with deionized water, and then ultrasonically cleaned with acetone / absolute ethanol mixed solution with a volume ratio of 0.8:1 at room temperature for 10 minutes to remove surface oil stains, and the base material was taken out and air-dried naturally;

[0051] (2) Perform fluorination treatment on the cleaned substrate material, the concentration of hydrofluoric acid is 30wt%, the fluorination treatment time is 24 hours, and the substrate material that has undergone fluorination treatment is cleaned with deionized water and then dried;

[0052] (3) Configure electrolyte: Ca(NO 3 ) 2 4H 2 O 21.5mmol / L

[0053] NH 4 h 2 PO 4 12.8 mmol / L

[0054] NaNO 3 0.09 mmol / ...

Embodiment 3

[0060] Prepare a composite coating on the surface of high-purity magnesium (99.99%) to obtain fluorine-containing nano-hydroxyapatite. The preparation steps are as follows:

[0061] (1) Substrate material preparation: cutting the magnesium wire 12mm×3mm cylinder, use 240 # 、600 # , 800 # 、1000 # The surface of the alloy was polished with SiC water-grinding paper in turn, rinsed with deionized water, and then ultrasonically cleaned with acetone / absolute ethanol mixed solution with a volume ratio of 0.6:1 at room temperature for 10 minutes to remove surface oil stains, and the base material was taken out and air-dried naturally;

[0062] (2) Perform fluorination treatment on the cleaned base material, the concentration of hydrofluoric acid is 20wt%, the fluorination treatment time is 30 hours, and the base material that has undergone fluorination treatment is cleaned with deionized water and then dried;

[0063] (3) Configure electrolyte: Ca(NO 3 ) 2· 4H 2 O 0.042 mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com