Totally-closed liquid-state cathode rare earth fused salt electrolytic cell

A technology of liquid cathode and molten salt electrolysis, which is applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve problems such as insufficient electrolytic cells, and achieve the effects of reducing consumption costs, reducing metal dissolution losses, and reducing secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

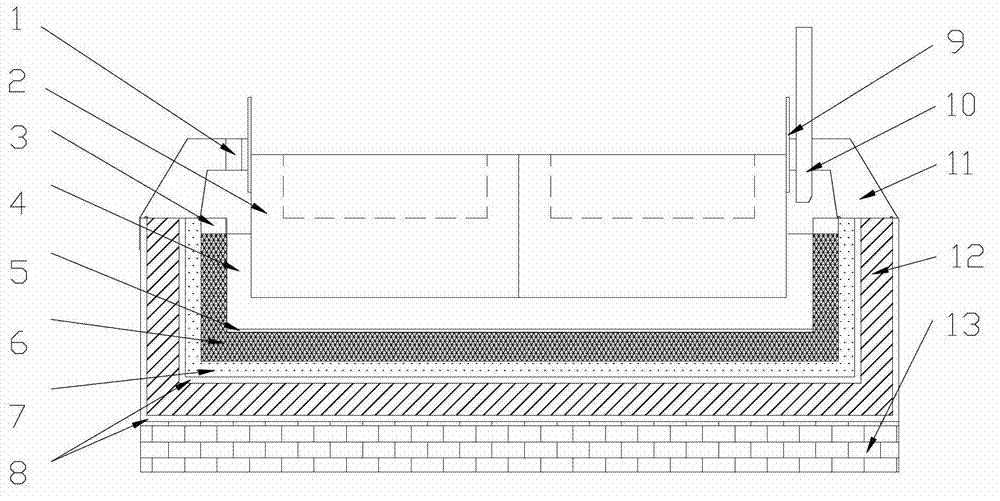

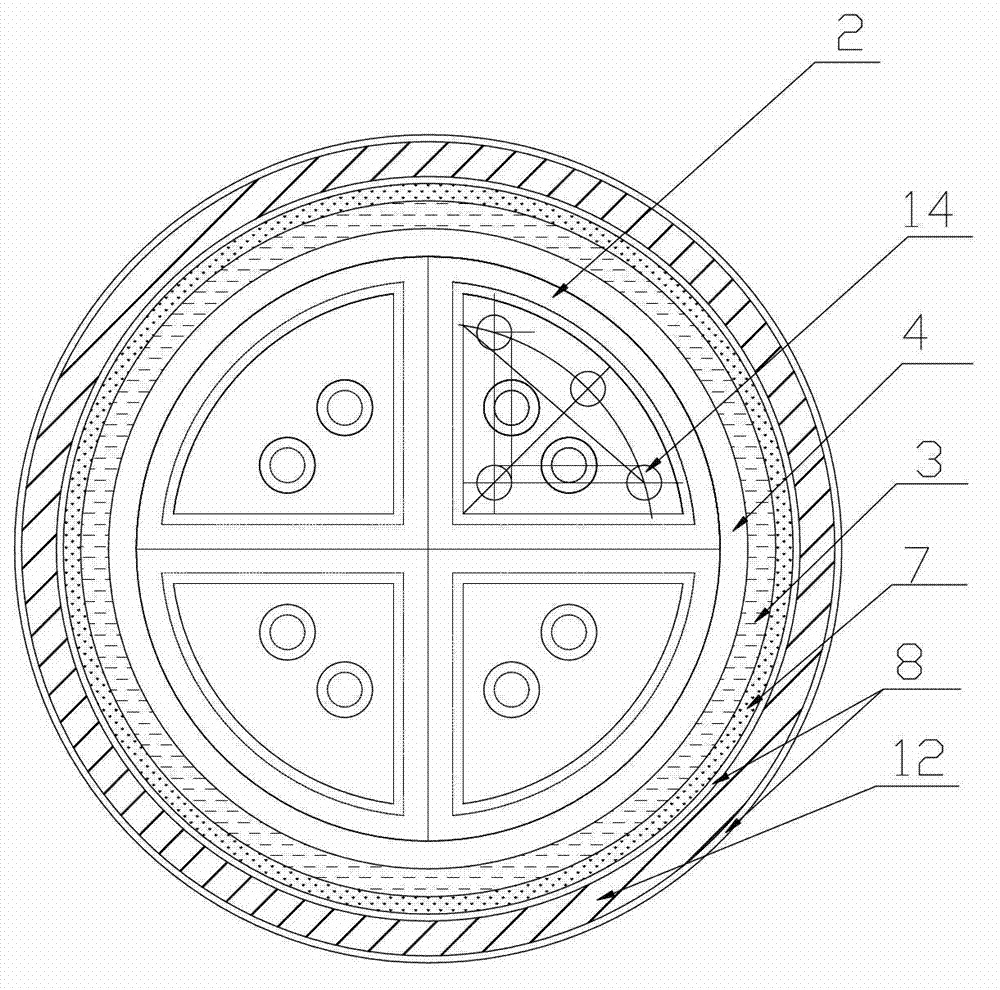

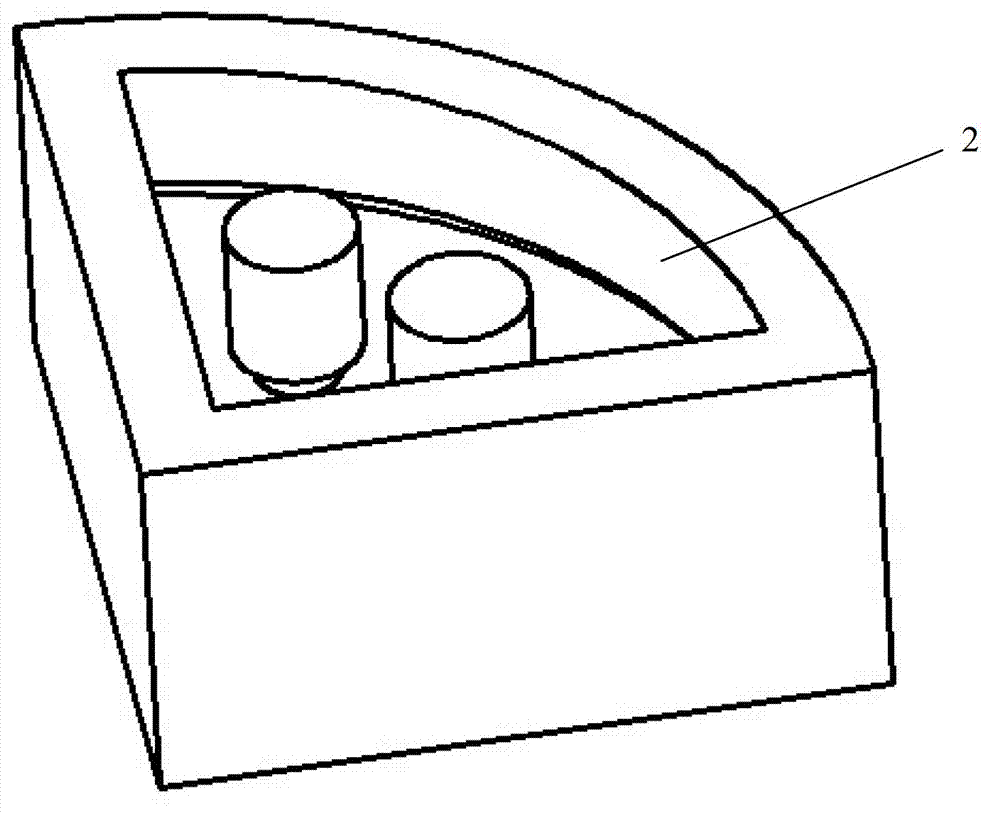

[0022] Such as figure 1 As shown, a fully enclosed liquid cathode rare earth molten salt electrolytic cell of the present invention includes a double-layer iron sheet tank 8 arranged on a refractory brick 13, and a refractory cement 12 is arranged between the inner layer and the outer layer of the double-layer iron sheet tank 8 , the graphite tank body 6 is located in the double-layer iron sheet tank 8, graphite powder 7 is filled between the inner layer of the double-layer iron sheet tank 8, the bottom of the graphite tank body 6 has a liquid cathode 5, and the molten salt electrolyte 4 is on the liquid cathode 5 , The graphite tank body 6 is equipped with an annular tank cover 11 , and the upper end of the graphite tank body 6 is provided with a corundum gasket 3 . The annular groove cover 11 is connected to the motor to rotate, and the corun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com