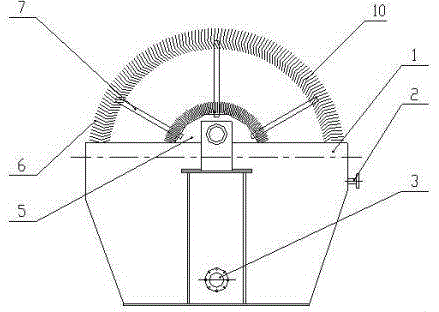

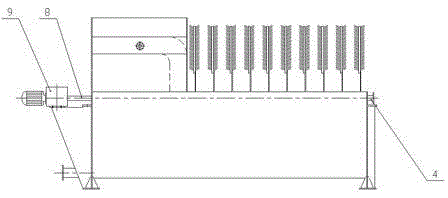

Automatic oxygenation biotransfer device

A bio-transfer film and automatic oxygenation technology, applied in the field of wastewater treatment, can solve the problems of low COD pollution load of pure oxygen aeration, unsatisfactory biochemical treatment effect of wastewater, and uncompleted process, so as to achieve less sludge output, Good dehydration performance, increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Domestic sewage in a residential area, the treatment scale is 200m 3 / d, influent COD is 185mg / L, SS is 70mg / L, TP is 3mg / L, NH 3 -N is 30mg / L. The grid is used to remove slag, the adjustment tank is homogeneous, and the sewage flows into the automatic oxygenation type bio-transfer film device of the present invention after the hydraulic retention time is 7h. The hydraulic retention time is HRT=1.5h, and the post-treatment adopts the form of inclined tube precipitation and ozone sterilization . The effluent COD is 60mg / L, SS is 20mg / L, TP is 1mg / L, NH 3 -N is 12 mg / L. COD removal rate was 68%, SS removal rate was 71%, TP removal rate was 67%, NH 3 -N removal rate is 60%. The effluent indicators of the system meet the first-level discharge requirements of the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

Embodiment 2

[0036] Domestic sewage (septic tank) of an administrative office building, the treatment scale is 150L / d, the influent COD is 132mg / L, SS is 50mg / L, TP is 2.5mg / L, NH 3 -N is 35mg / L. After being homogenized in the regulating tank, the sewage flows into the automatic oxygenation type bio-transfer film device of the present invention after the hydraulic retention time is 6h, and the hydraulic retention time is HRT=2h, and the post-treatment adopts the form of advection sedimentation and chlorine dioxide sterilization. The effluent COD is 40mg / L, SS is 10mg / L, TP is 0.5mg / L, NH 3 -N is 10 mg / L. COD removal rate is 70%, SS removal rate is 80%, TP removal rate is 80%, NH 3 -N removal rate was 71%. The effluent index of the system complies with the "Pollutant Discharge Standards for Urban Sewage Treatment Plants".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com