Composite fire retardant for bituminous mixture

A technology for compounding flame retardants and asphalt mixtures, applied in the field of road asphalt materials, can solve the problems of different flame retardant effects, low flame retardant efficiency, and poor environmental performance of flame retardants, and achieves improved synergistic flame retardant effect, The effect of promoting dehydration carbonization and high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

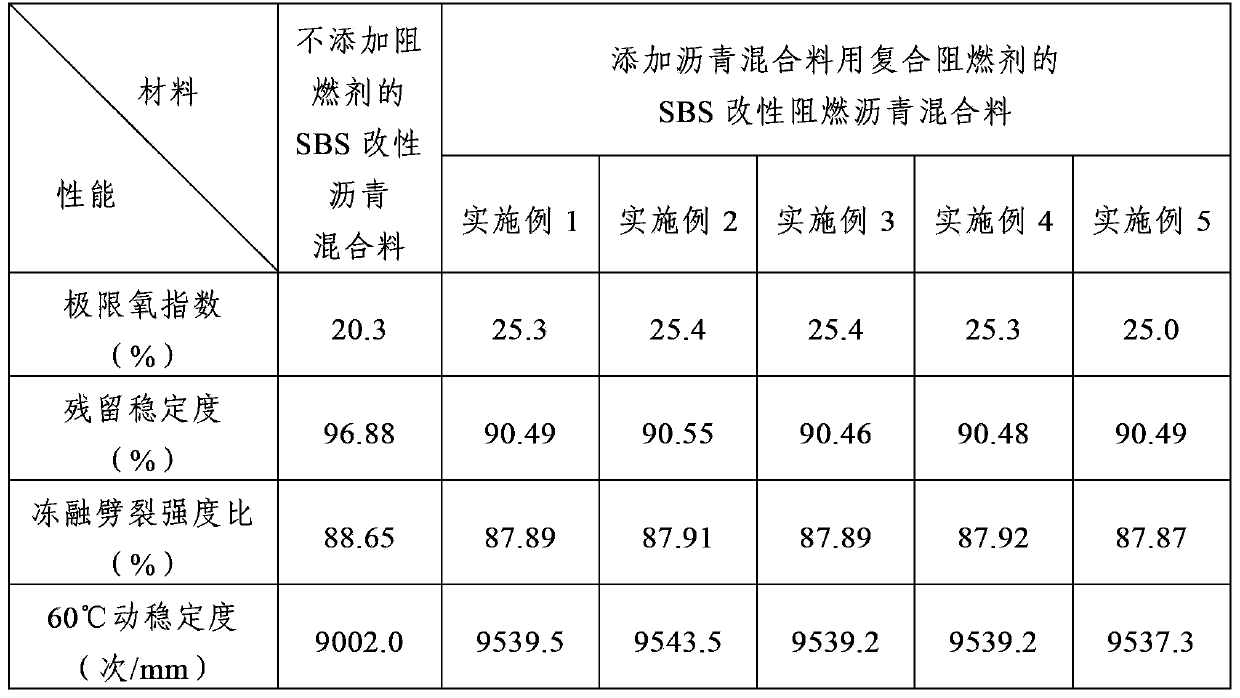

Embodiment 1

[0019] The composite flame retardant for asphalt mixture in this example is made by mixing and ball milling the following raw materials in parts by weight: 22 parts of ammonium polyphosphate, 6 parts of melamine, 1.5 parts of pentaerythritol, 707 parts of chlorinated paraffin, 4 parts of zinc borate, dry powder interface 0.4 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 350r / min, and the time of the ball milling is 35min.

Embodiment 2

[0021] The composite flame retardant for asphalt mixture in this example is made by mixing and ball milling the following raw materials in parts by weight: 21 parts of ammonium polyphosphate, 7 parts of melamine, 2 parts of pentaerythritol, 708 parts of chlorinated paraffin, 5 parts of zinc borate, dry powder interface 0.5 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 360r / min, and the time of the ball milling is 38min.

Embodiment 3

[0023] The composite flame retardant for asphalt mixture in this example is made by mixing and ball milling the following raw materials in parts by weight: 20 parts of ammonium polyphosphate, 5 parts of melamine, 3 parts of pentaerythritol, 709 parts of chlorinated paraffin, 6 parts of zinc borate, dry powder interface 0.3 parts of agent; preferably, the dry powder interface agent is redispersible latex powder, the speed of the ball milling is 420r / min, and the time of the ball milling is 32min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com