A kind of flame retardant based on modified α-zirconium phosphate and its preparation method

A zirconium phosphate modification technology, which is applied in fibrous fillers, coatings, dyed low-molecular organic compounds, etc., can solve the problems of low loose strength of the charcoal layer, poor charcoal quality, low flame retardant efficiency, etc., to achieve Easy intercalation and peeling, adjustable layer spacing, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

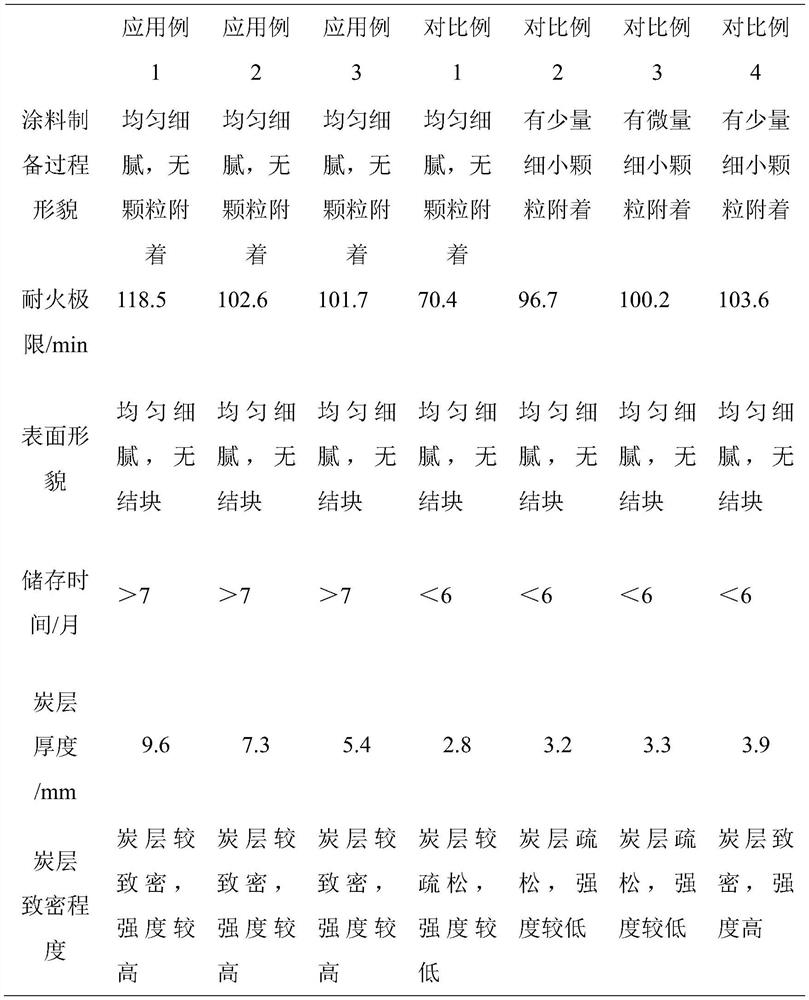

Examples

Embodiment 1

[0036] A novel nano-flame retardant based on modified α-zirconium phosphate, the preparation method of which comprises the following steps:

[0037]1) Preparation of α-zirconium phosphate sheets: disperse 2.83g of α-zirconium phosphate in water by ultrasonic, stir well to make zirconium phosphate suspension, add 100ml of 0.2mol / L methylamine aqueous solution amine that has been prepared; 7.28g Cetyltrimethylammonium bromide (CTAB) was dissolved in 100ml water to prepare surfactant solution, and it was added dropwise in the mixed solution of zirconium phosphate and methylamine (controlling zirconium phosphate and cetyltrimethyl The molar ratio of ammonium bromide is 1:1), after the complete dropwise addition, the mixture was ultrasonicated at 75°C for 4h, then left at room temperature for 3h, filtered with suction, and rinsed with water until there was no bromide ion. The obtained organically modified zirconium phosphate was added to the organic medium, ultrasonicated for 60 mi...

Embodiment 2

[0041] A novel nano-flame retardant based on modified α-zirconium phosphate, the preparation method of which comprises the following steps:

[0042] 1) Preparation of α-zirconium phosphate sheets: disperse 2.83g of α-zirconium phosphate in water by ultrasonic, stir well to make zirconium phosphate suspension, add 100ml of 0.2mol / L methylamine aqueous solution amine that has been prepared; 7.28g Cetyltrimethylammonium bromide (CTAB) was dissolved in water to prepare a surfactant solution, and it was added dropwise to the mixed solution of zirconium phosphate and methylamine (control zirconium phosphate and cetyltrimethylbromide The molar ratio of ammonium chloride is 2:3), after the complete dropwise addition, the mixture was ultrasonicated at 80°C for 5h, then left at room temperature for 5h, suction filtered, and washed with water until there was no bromide ion. The obtained organically modified zirconium phosphate was added to the organic medium, ultrasonicated for 60 minute...

Embodiment 3

[0046] A novel nano-flame retardant based on modified α-zirconium phosphate, the preparation method of which comprises the following steps:

[0047] 1) Preparation of α-zirconium phosphate sheets: disperse 5.66g of α-zirconium phosphate in water by ultrasonic waves, stir well to make a zirconium phosphate suspension, add 100ml of 0.2mol / L methylamine aqueous solution that has been prepared; 11.32g Cetyltrimethylammonium bromide (CTAB) was dissolved in 100ml water to prepare surfactant solution, and it was added dropwise in the mixed solution of zirconium phosphate and methylamine (controlling zirconium phosphate and cetyltrimethyl The molar ratio of ammonium bromide is 4:3), after the complete dropwise addition, the mixture was subjected to ultrasound at 80°C for 5h, then placed at room temperature for 4h, suction filtered, and washed with water until no bromide ions were obtained; Add active zirconium phosphate into isopropanol, ultrasonicate for 60min, ball mill in a ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com