Carbon black colored ethylene-vinyl acetate copolymer color master batch and preparation method thereof

A technology of vinyl acetate copolymerization and carbon black, applied in the field of color masterbatch, can solve the problems of poor flame retardant performance of color masterbatch, easy combustion, poor compatibility between carbon black and ethylene-vinyl acetate copolymer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

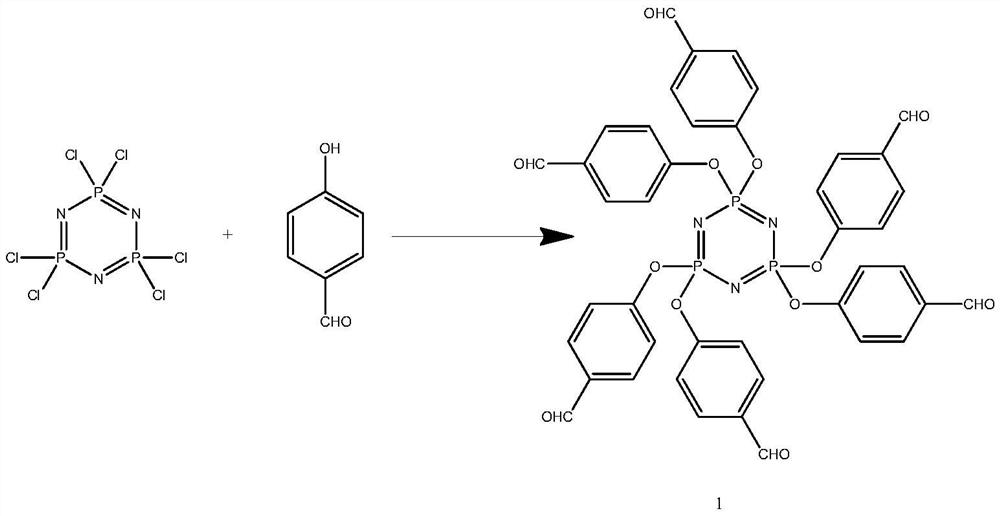

[0057] The present embodiment is a preparation method of a super flame retardant additive, comprising the following steps:

[0058] A1: Add 10 mmol of hexachlorocyclotriphosphazene, 65 mmol of p-hydroxybenzaldehyde, 100 mL of acetone and 13.5 g of potassium carbonate to a three-necked flask equipped with a stirrer, a thermometer and an airway, and introduce nitrogen protection at a temperature of 20 °C , stir for 15 minutes at a stirring rate of 300 r / min, then heat up to 70 °C while stirring, control the heating rate to 2 °C / min, and then continue to stir for 50 h. After the reaction, the reaction product was cooled to 5 °C, and then vacuumed Suction filtration, the filtrate was washed 3 times with sodium carbonate solution with a mass fraction of 10%, distilled water and n-hexane in turn, then recrystallized in ethyl acetate, and then placed in a vacuum drying box at a temperature of 70 ° C. Dry to constant weight to obtain Intermediate 1;

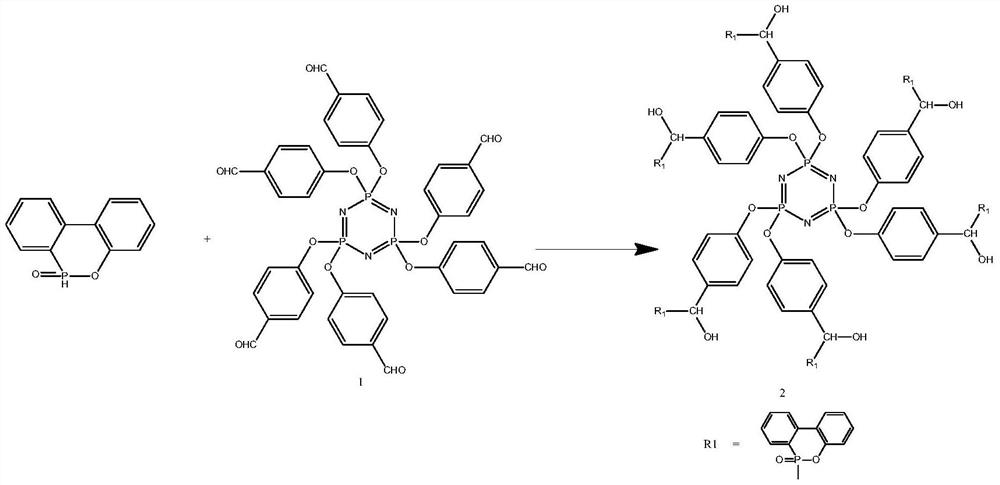

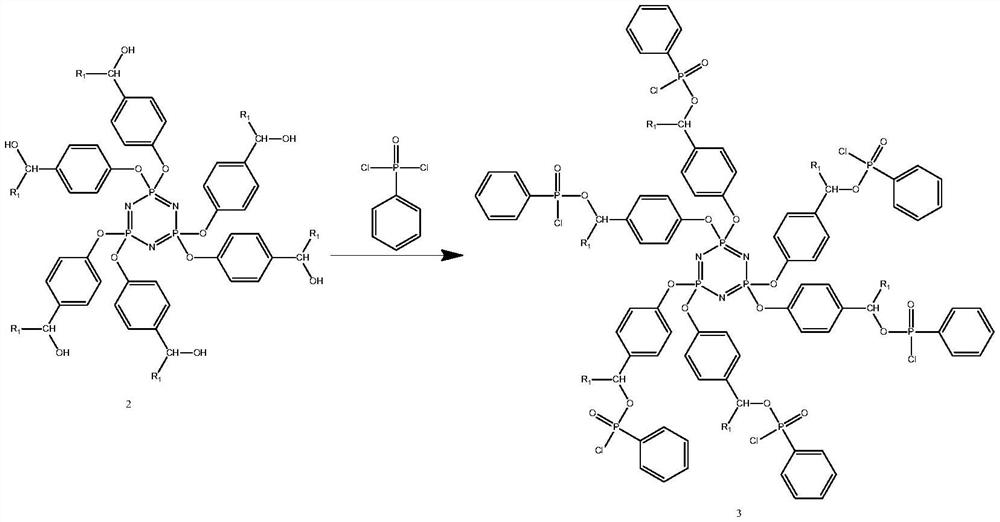

[0059] A2: Add 10 mmol of Interm...

Embodiment 2

[0064] The present embodiment is a preparation method of a super flame retardant additive, comprising the following steps:

[0065] A1: Add 10 mmol of hexachlorocyclotriphosphazene, 70 mmol of p-hydroxybenzaldehyde, 120 mL of acetone and 14.5 g of potassium carbonate to a three-necked flask equipped with a stirrer, a thermometer and an airway, and introduce nitrogen protection at a temperature of 30 °C , stir for 25 minutes at a stirring rate of 500 r / min, then heat up to 75 °C while stirring, control the heating rate to 3 °C / min, and then continue to stir the reaction for 70 h. After the reaction, the reaction product was cooled to 10 °C, and then vacuumed Suction filtration, the filtrate was washed 5 times with 15% sodium carbonate solution, distilled water and n-hexane in turn, then recrystallized in ethyl acetate, and then placed in a vacuum drying box, at a temperature of 75 ℃. Dry to constant weight to obtain Intermediate 1;

[0066]A2: Add 10 mmol of Intermediate 1, 70...

Embodiment 3

[0071] The present embodiment is a preparation method of high dispersibility carbon black, comprising the following steps:

[0072] B1: Add 10g of carbon black and 50mL of hydrogen peroxide solution with a mass fraction of 30% into a three-necked flask equipped with a stirrer and a thermometer, stir and react for 8h at a temperature of 78°C and a stirring rate of 300r / min, After the reaction is completed, the reaction product is cooled to room temperature, then washed with distilled water until neutral, and then placed in a vacuum drying oven, and dried to constant weight at a temperature of 60 ° C to obtain oxidatively modified carbon black;

[0073] B2: Add 10g of oxidatively modified carbon black and 120mL of toluene into a three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a gas guide, and stir for 30min at a temperature of 20°C and a stirring rate of 300r / min. After that, nitrogen protection was introduced, and 3.5 g of silane coupling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com