Beta-mannase, coding gene as well as producing strain and application thereof

A mannanase and gene technology, which is applied in the field of genetic engineering to achieve the effects of good heat resistance and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1. Screening of Aspergillus sp.T16 producing high temperature β-mannanase

[0051] The soil samples collected from the orange orchard in Yuelu Mountain, Changsha City, Hunan Province were enriched and cultured (enriched medium: 0.5% konjac flour was dissolved in basal salt medium, pH was adjusted to 5.0, 30°C, 200rpm) for 48 hours. Dilute the enriched medium by 10 4 -10 6 After doubling, each 0.2mL was coated with a primary screening plate (1.5% agar powder and 0.2% Congo red were added to the enrichment medium), and cultured at a constant temperature of 30°C for 2-3 days. After the primary screening plate grows, when a transparent hydrolysis circle appears around the colony, it is picked and inoculated in a 24-well cell culture plate containing enriched medium, and cultured at 30°C and 200rpm for 48h. Take the supernatant of the culture medium and dilute it to an appropriate multiple, use 0.5% locust bean gum as the substrate, measure the enzyme activity in t...

Embodiment 2

[0054] Example 2. Obtaining the whole gene of high-temperature β-mannanase from the fungus Aspergillus sp.T16

[0055] 1. High temperature β-mannanase N-terminal and C-terminal amino acid sequence sequencing

[0056] Aspergillus sp.T16 was cultured in induction medium (0.5% konjac flour and 1.0% peptone dissolved in basal salt medium, pH 5.0, 35°C, 200rpm) for 48 hours, the mycelium was removed by gauze filtration, and the culture supernatant was dialyzed After bag concentration, dialysis and SephadexTM G-75 gel purification, N and C-terminal amino acid sequencing was carried out. The N-terminal sequence was SFASTSGLQF, and the C-terminal sequencing result was TDHVAAIGSA. The two were derived from Aspergillus usamii (ADZ99027.1), Aspergillus kawachii (GAA89125.1), Aspergillus niger (ACJ06979.1, ADK88903.1, AEY76082.1) and Aspergillus sulphureus (ABC59553.1) have high homology; For gene sequence alignment, the upstream degenerate primer ManTF-5TCCTTCGCCAGCACCTCSGG3 and the dow...

Embodiment 3

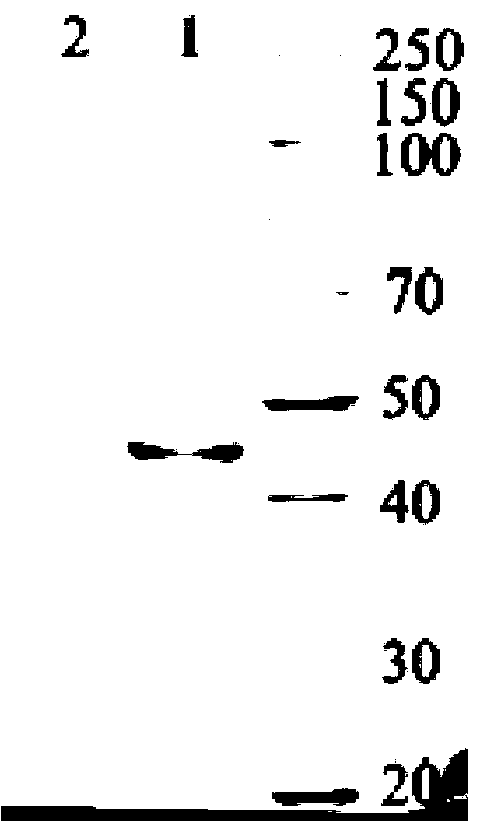

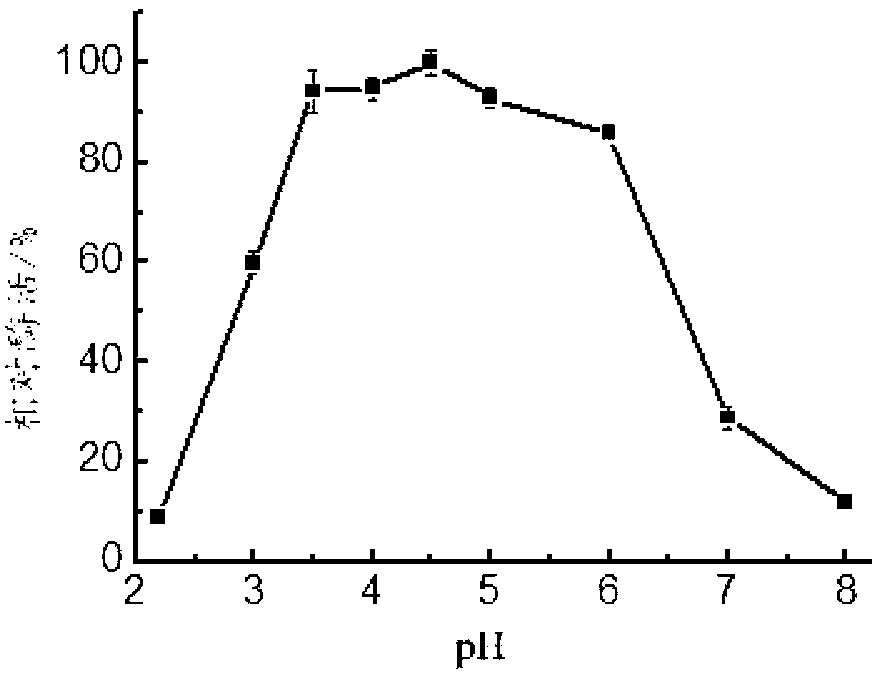

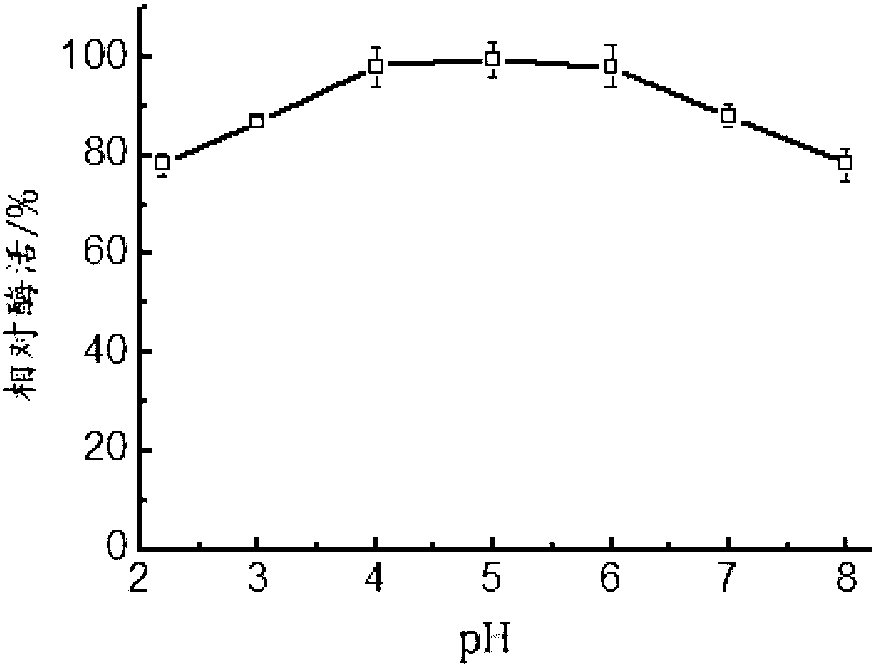

[0061] Embodiment 3, the preparation of recombinant high-temperature β-mannanase

[0062] Synthesize primers ManPF-5CCGCTCGAGAAAAGAGAGGCTGAAGCTTCCTTCGCCAGCACCTCCGG3 (C^TCGAG is the Xho I restriction site) and ManPR-5GCTCTAGATCAAGCACTACCAATAGCAGCAACATG3 (T^CTAGA is the Xba I restriction site) according to the cDNA sequence encoding the mature high-temperature β-mannanase, for example The cDNA sequence encoding the mature high-temperature β-mannanase obtained in 2 was used as a template for PCR amplification. The PCR amplification parameters were: denaturation at 95°C for 5 minutes; denaturation at 94°C for 1 minute, deactivation at 52°C for 1 minute, and extension at 72°C for 2 minutes. 30 cycles; fully extended at 72°C for 15min.

[0063] The pGAPZαA and pPICZαA plasmids were double-digested with Xho I and Xba I, and the above PCR products were double-digested at the same time, and the double-digested PCR products were ligated with the double-digested pGAPZαA and pPICZαA plasm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com