Branching treatment method of pulp paper sludge and application of branching treatment products thereof

A treatment method and branched technology, applied in sludge treatment, water/sludge/sewage treatment, biological organic part treatment, etc. Eliminate the effects of valuable land occupation, increased investment costs, huge economic benefits and social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

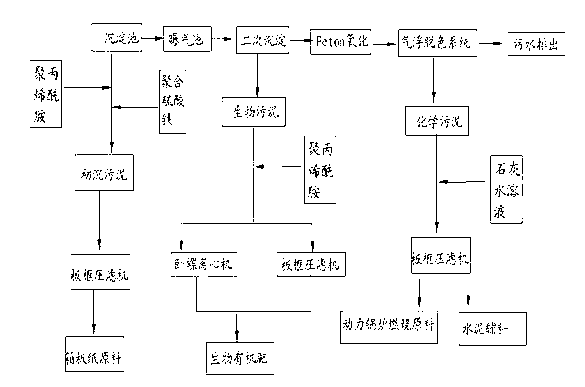

[0030] Embodiment one: if figure 1 The flow chart of the method for branching pulp and paper sludge treatment of the present invention is shown, the method includes the following steps: (1) sediment the pulp and paper sludge for 5 to 6 hours, separate the sewage and solids in the pulp and paper sludge, and separate The solid content discharged is primary sludge; some fibrous solid waste in the pulping workshop and cardboard workshop wastewater of pulp and paper mills forms pulp and paper sludge, and the temperature when it is discharged from the workshop to the sewage plant sump is generally 60-60℃. 70°C, the temperature will be cooled to 37-40°C after the heat exchange of the plate heat exchanger, and then the pulp and paper sludge will undergo natural gravity sedimentation in the primary sedimentation tank to separate the sewage and solids, the first step of separation The solid content that comes out is the primary sludge.

[0031] (2) Pass the sewage separated in step (1...

Embodiment 2

[0050] Embodiment 2: The branch treatment method of the pulp and paper sludge of the present invention comprises the following steps: (1) Precipitating the pulp and paper sludge for 5 to 6 hours to separate the sewage and solids in the pulp and paper sludge, and the separated solids The content is primary sludge;

[0051] (2) Pass the sewage separated in step (1) into the aeration tank; dehydrate the separated primary sludge so that the mass fraction of dry solids reaches 50%, and obtain the first branch treatment product;

[0052] (3) The sewage in the aeration tank in step (2) is aerated for 8 to 12 hours to form aerated sewage, and then the aerated sewage is precipitated for 2 to 4 hours to separate the solids in the aerated sewage, and the separated The solid content is biological sludge;

[0053] (4) For the aerated sewage separated in step (3), the Fenton oxidation method was used for oxidative decolorization; the separated biological sludge was dehydrated so that the mas...

Embodiment 3

[0065] Embodiment 3: The branch treatment method of the pulp and paper sludge of the present invention comprises the following steps: (1) Precipitating the pulp and paper sludge for 5 to 6 hours to separate the sewage and solids in the pulp and paper sludge, and the separated solids The content is primary sludge;

[0066] (2) Pass the sewage separated in step (1) into the aeration tank; dehydrate the separated primary sludge so that the mass fraction of dry solids reaches 75%, and obtain the first branch treatment product;

[0067] (3) The sewage in the aeration tank in step (2) is aerated for 8 to 12 hours to form aerated sewage, and then the aerated sewage is precipitated for 2 to 4 hours to separate the solids in the aerated sewage, and the separated The solid content is biological sludge;

[0068] (4) For the aerated sewage separated in step (3), the Fenton oxidation method was used for oxidative decolorization; the separated biological sludge was dehydrated so that the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com