Preparation method of wave-transparent fiber toughened boron nitride ceramic based wave-transparent composite material

A technology of fiber toughening and composite materials, which is applied in the field of preparation of wave-transparent fiber-toughened boron nitride ceramic-based wave-transparent composite materials, which can solve the problems of high preparation temperature, low ceramicization degree and low density of the substrate, and reduce the Preparation temperature, excellent wave-transmitting performance, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

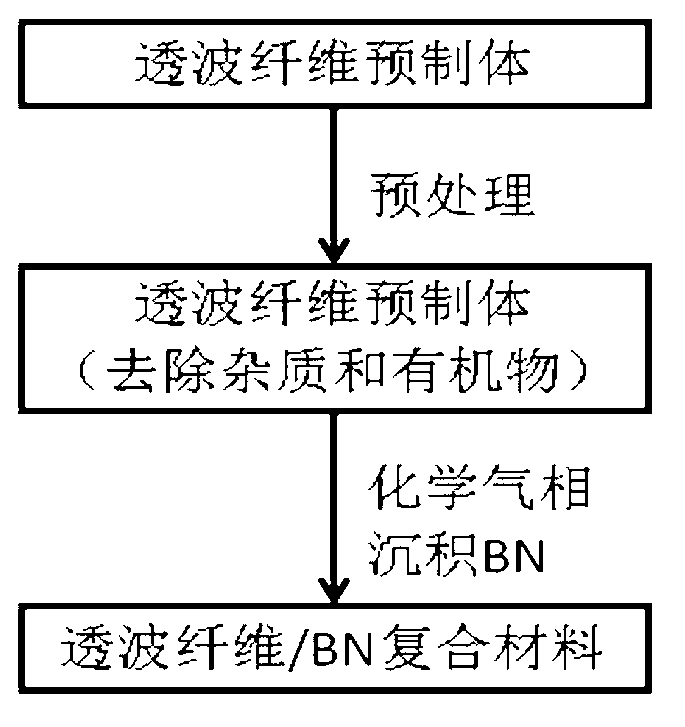

Method used

Image

Examples

Embodiment 1

[0020] (1) Put 20 pieces of 10cm×10cm×0.01cm glass fiber square cloth (0° / 90°) into a sealed autoclave filled with acetone, heat to 100°C, and keep it warm for 1h. Then put it in a muffle furnace (air atmosphere), raise it to 400°C, and keep it warm for 2h.

[0021] (2) The pretreated fiber prefabricated body is layered and formed in a graphite fixture, placed in a BN chemical vapor infiltration furnace, and BCl is introduced at the same time 3 , NH 3 , Ar and H 2 . BCl 3 The flow rate is 40ml / min, NH 3 Flow rate is 70ml / min, Ar flow rate is 50ml / min, H 2 The flow rate is 110ml / min. Keep the pressure in the furnace at 1kPa, deposit the BN matrix in the temperature range of 650°C, and the deposition time is 150h. The waste materials around the material are cut off and cleaned to obtain the glass fiber reinforced BN matrix composite material.

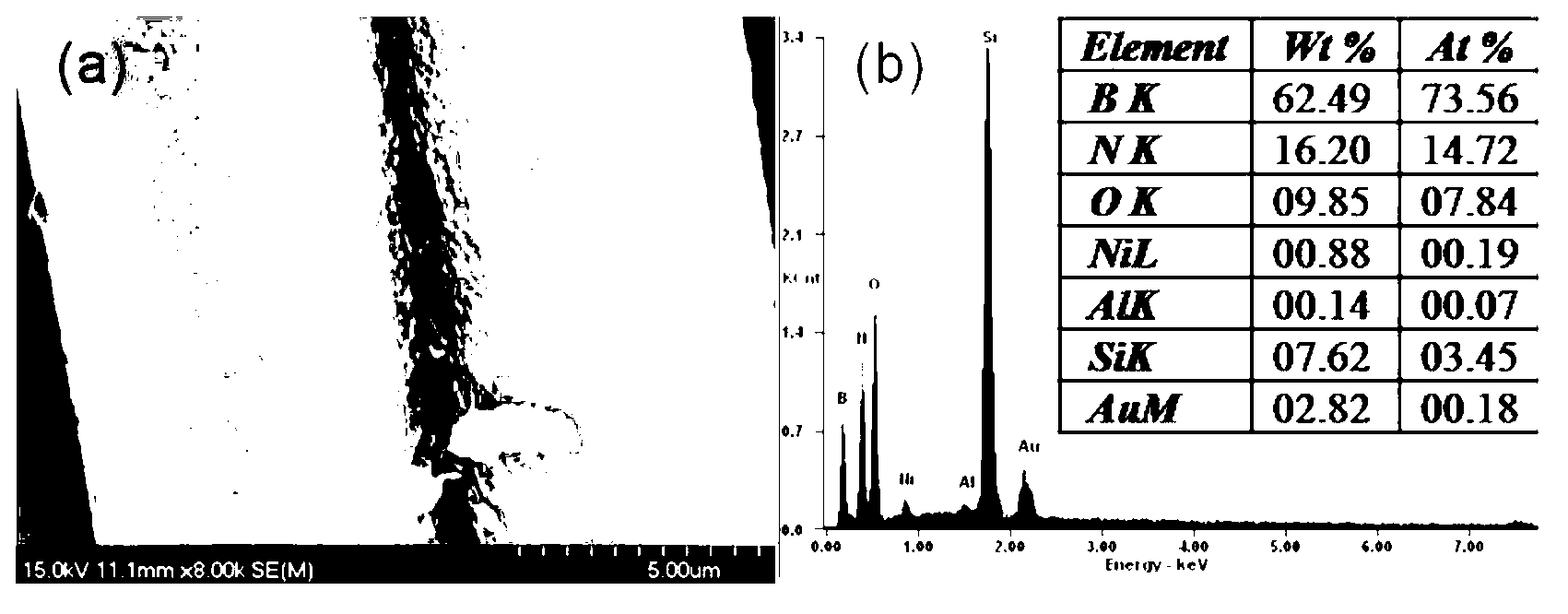

[0022] It is measured that the composite material whose prepared glass fiber is the reinforcement body density is 1.56g / cm 3 . ...

Embodiment 2

[0025] (1) Preform the glass fiber 2.5D fiber. Put it into a sealed autoclave filled with acetone, heat to 80°C, and keep it warm for 2h. Then place it in a muffle furnace (air atmosphere), raise it to 400°C, and keep it warm for 2h.

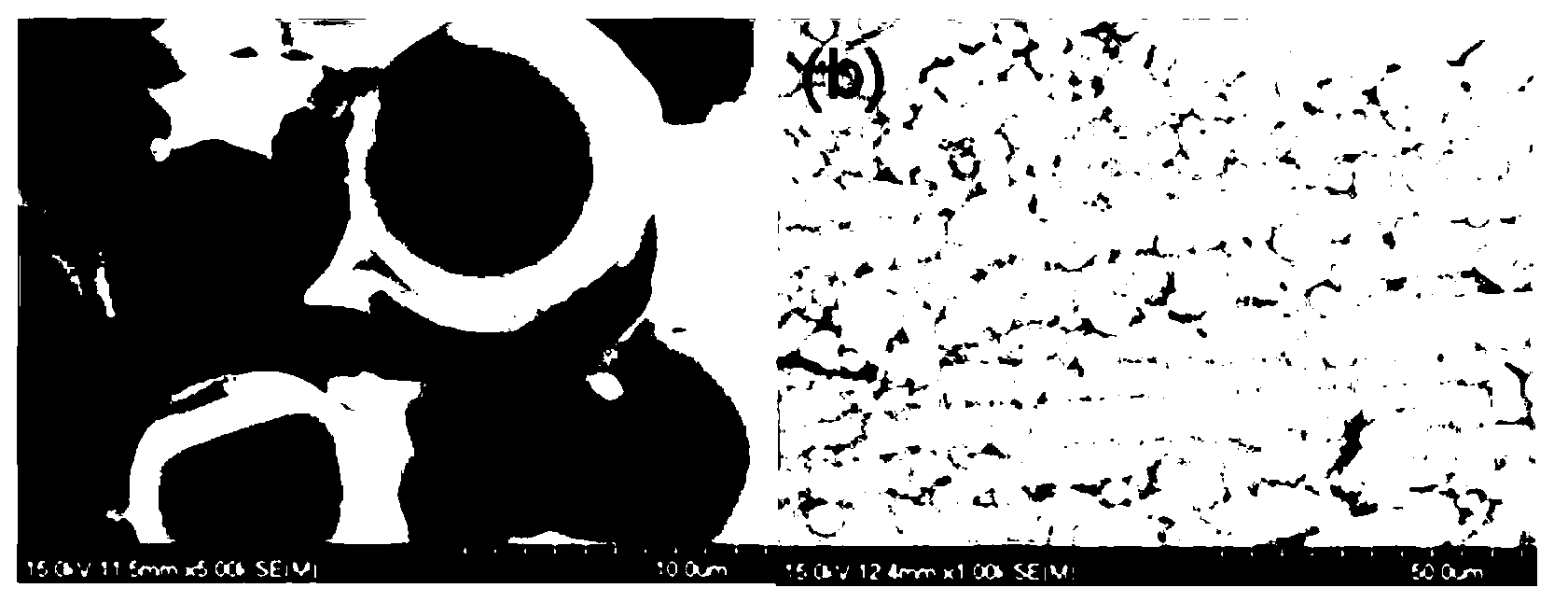

[0026] (2) Put the pretreated fiber preform into the BN chemical vapor infiltration furnace, using BCl 3 -NH 3 -Ar-H 2 system. A relatively small flow rate is used to slow down the deposition rate and improve permeability, and the gas flow rates are 20ml / min, 40ml / min, 40ml / min, and 90ml / min, respectively. Keep the pressure in the furnace at 1kPa, deposit the BN matrix in the temperature range of 650°C, and the deposition time is 180h. The waste materials around the material are cut off and cleaned to obtain the glass fiber reinforced BN matrix composite material.

[0027] Measure the average bulk density and process the sample into a disk with a diameter of 50mm and a thickness of 4mm. The relative permittivity of the material is measured...

Embodiment 3

[0030] (1) The glass fiber three-dimensional fiber prefabricated body. Put it into a sealed autoclave filled with acetone, heat to 80°C, and keep it warm for 2h. Then place it in a muffle furnace (air atmosphere), raise it to 400°C, and keep it warm for 2h.

[0031] (2) Put the pretreated fiber preform into the BN chemical vapor infiltration furnace, using BCl 3 -NH 3 -Ar-H 2 system. The gas flow rates are 10ml / min, 30ml / min, 30ml / min, 70ml / min respectively. Keep the pressure in the furnace at 7kPa, deposit the BN matrix in the temperature range of 650°C, and the deposition time is 200h. The waste materials around the material are cut off and cleaned to obtain the glass fiber reinforced BN matrix composite material.

[0032] Measure the average bulk density and process the sample into a disc with a diameter of 50mm and a thickness of 4mm. The relative permittivity of the material is measured by the resonant cavity method. The measured volume density of the three-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap