Preparation method of caprolactone lactate copolymer/collagen/chitosan small-caliber intravascular stent

A collagen and vascular stent technology, which is applied in the field of preparation of lactic caprolactone copolymer/collagen/chitosan small-diameter vascular stents, can solve the problem of poor biocompatibility of polymer nanofibers and inability to reach vascular tissue Engineering scaffold requirements, poor mechanical properties of natural materials, etc., to achieve the effect of promoting three-dimensional ingrowth of cells, excellent biocompatibility, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

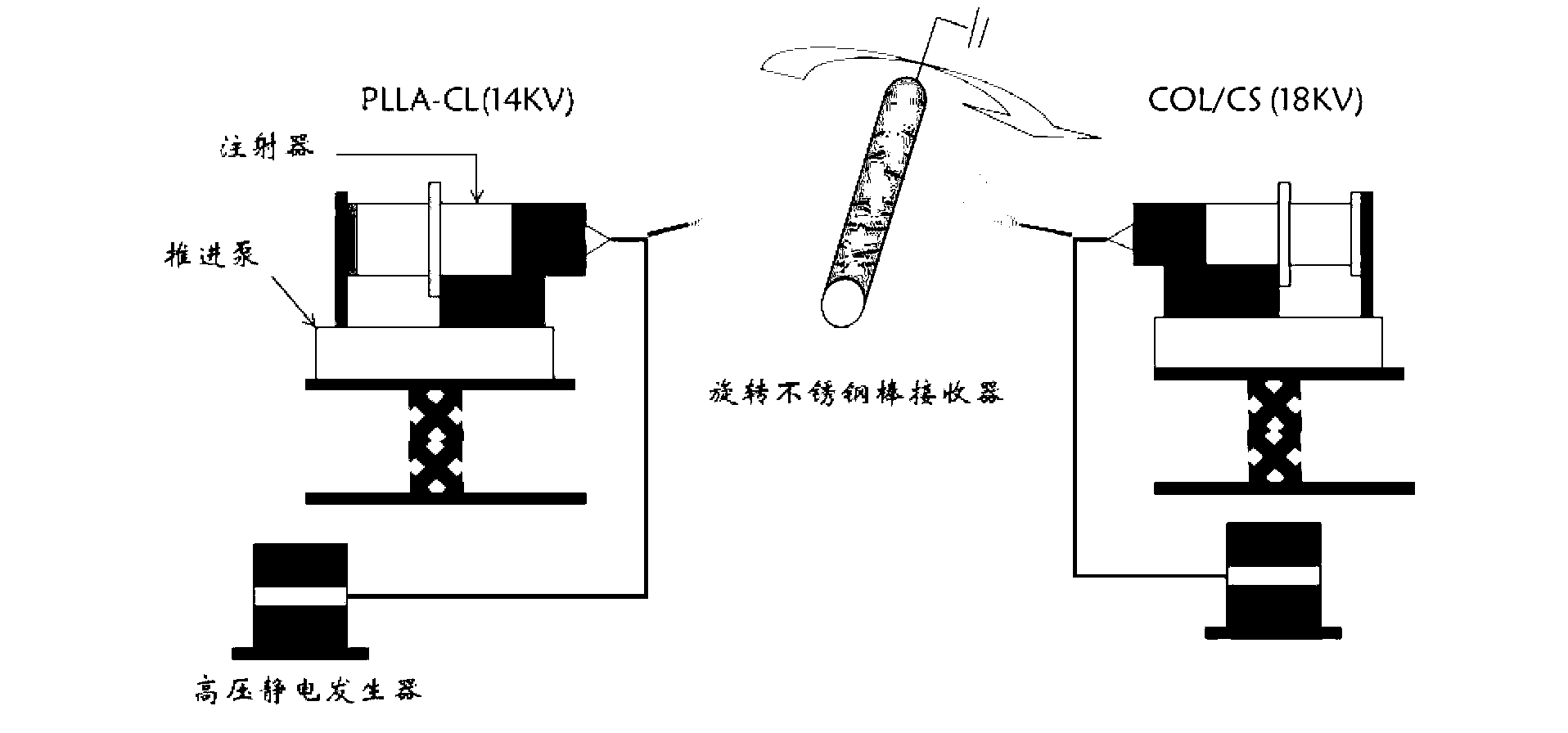

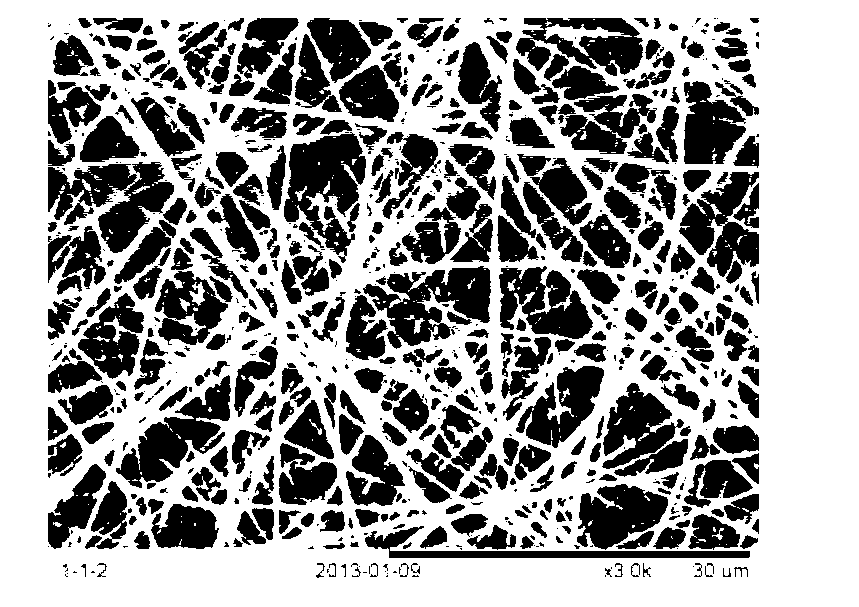

[0029] Take the caprolactone lactate copolymer and collagen and the chitosan of 0.3g with an electronic balance; the caprolactone lactone copolymer of 0.4g is dissolved in 5ml hexafluoroisopropanol, magnetically stirred until completely dissolved; dissolve 0.4g of collagen in 5ml hexafluoroisopropanol, and magnetically stir until completely dissolved; dissolve 0.3 of chitosan in 5ml hexafluoroisopropanol / trifluoroacetic acid (V / V, 9 / 1) Mix the solvents and stir until they are completely dissolved; after the three solutions are completely dissolved, the caprolactone lactone copolymer spinning solution is used as component 1, and 4.5mL of collagen spinning solution and 0.5mL of chitosan are used for spinning The solution is mixed evenly as component 2, and the two-way electrospinning method is used to suck the spinning solution of component 1 and component 2 into a 5mL syringe respectively, connect the No. The pump adjusts the flow rate (mL / h) of component 1 and component 2 as ...

Embodiment 2

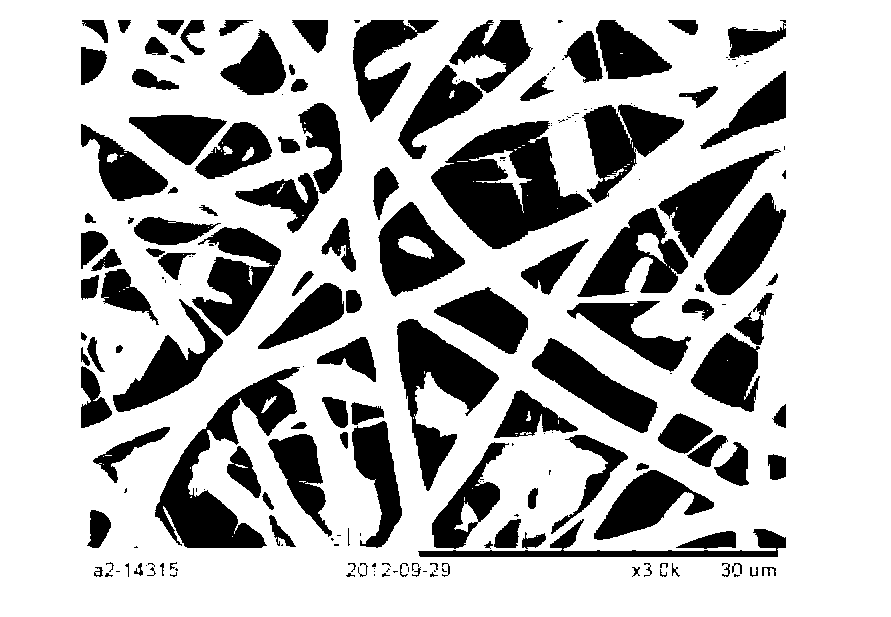

[0031] Take the caprolactone lactate copolymer and collagen and the chitosan of 0.3g with an electronic balance; the caprolactone lactone copolymer of 0.4g is dissolved in 5ml hexafluoroisopropanol, magnetically stirred until completely dissolved; 0.4g of collagen was dissolved in 5ml hexafluoroisopropanol, magnetically stirred until completely dissolved; 0.3g of chitosan was dissolved in 5ml hexafluoroisopropanol / trifluoroacetic acid (V / V, 9 / 1) Mix the solvents and stir until they are completely dissolved; after the three solutions are completely dissolved, the caprolactone lactone copolymer spinning solution is used as component 1, and 4.5mL collagen spinning solution and 0.5mL chitosan spinning solution are taken. The silk liquid is mixed evenly as component 2, and the two-way electrospinning method is used to suck the spinning solution of component 1 and component 2 into a 5mL syringe respectively, connect the No. The syringe pump adjusts the flow rate (mL / h) of component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com