3D printing artificial blood vessel and preparation method thereof

An artificial blood vessel, 3D printing technology, applied in the direction of blood vessels, human tubular structure devices, non-woven fabrics, etc., can solve the problems of small diameter of the tube wall, easy to seep blood, and difficult for cells to grow in three-dimensionally, and achieves simple and economical operation. High efficiency and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

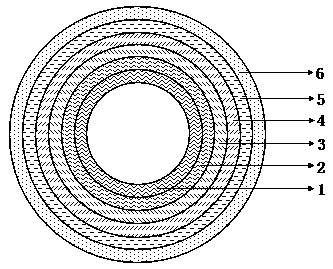

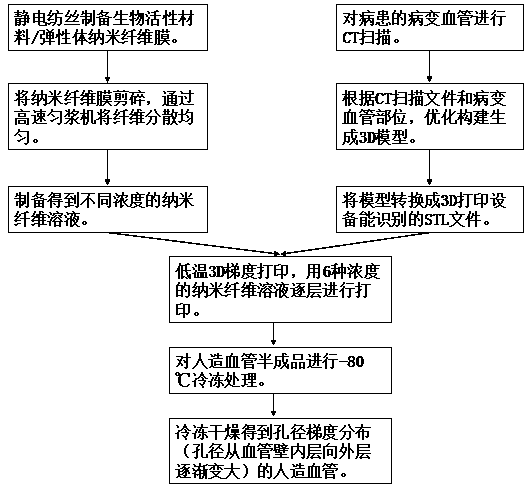

[0032] like figure 1 , the 3D printed artificial blood vessel contains a six-layer structure, which is the first layer, the second layer, the third layer, the fourth layer, the fifth layer, and the sixth layer from the inside to the outside. The preparation method is as follows: figure 2 ,include

[0033] 1) Prepare bioactive material / elastomer polymer composite nanofibrous membrane by electrospinning.

[0034] 2) Shredding the nanofiber membrane, placing it in a solvent and using a high-speed homogenizer to disperse the fibers evenly;

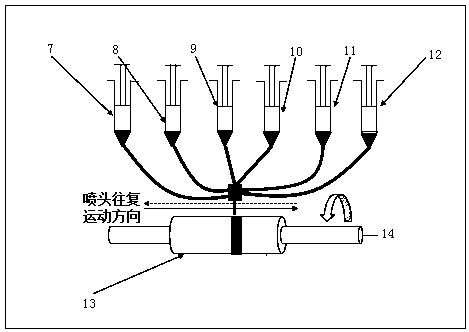

[0035] 3) Prepare nanofiber solutions for 3D printing with different concentrations, which are the first solution 7, the second solution 8, the third solution 9, the fourth solution 10, the fifth solution 11 and the sixth solution 12, such as image 3 .

[0036] 4) Use 3D printing technology to prepare semi-finished artificial blood vessels by printing nanofiber solutions with different concentrations layer by layer at low temperature;

...

Embodiment 1

[0042] The nanofibrous membrane of collagen / caprolactone lactate copolymer composite was prepared by electrospinning. The spinning parameters were: the mass ratio of collagen and caprolactone lactate copolymer was 25:75, and the solvent was hexafluoroisopropanol. The concentration of the spinning solution is 10%, and the feeding rate of the spinning solution is 1.5mL / h.

[0043] Cut the nanofiber membrane into pieces, place it in a glycerol solvent, and use a high-speed homogenizer to disperse the fibers evenly, and prepare collagen / lactic acid with a concentration of 75%, 65%, 55%, 45%, 35%, and 25%. Caprolactone copolymer nanofiber solution. The above-mentioned nanofiber solution is vacuum degassed for use.

[0044] Through the CT scan file of the recipient lesion vessel, it was determined that the outer diameter of the artificial vessel was 5.8mm and the length was 23mm. According to clinical experience, the wall thickness of the required artificial blood vessel is determ...

Embodiment 2

[0053] The nanofiber membrane of silk fibroin / caprolactone lactate copolymer composite was prepared by electrospinning, the spinning parameters were: the mass ratio of silk fibroin and caprolactone lactate copolymer was 20:80, and the solvent was hexafluoroisopropyl alcohol, the spinning solution concentration is 11.5%, and the spinning solution feeding rate is 1mL / h.

[0054] Cut the silk fibroin / lactate caprolactone copolymer nanofiber membrane into pieces, put it in deionized water and use a high-speed homogenizer to disperse the fibers evenly, and prepare the resulting concentration at 80%, 70%, 60%, 50%, and 40%. , 25% collagen / lactate caprolactone copolymer nanofiber solution. The above-mentioned nanofiber solution is vacuum degassed for use.

[0055] Through the CT scan file of the recipient lesion vessel, it is determined that the outer diameter of the artificial vessel is 4.5mm and the length is 30mm. According to clinical experience, the wall thickness of the requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com