Centralized collection and treatment method of a plurality of liquid organic chemical raw material volatile gases

A technology for centralized processing of chemical raw materials, applied in chemical instruments and methods, separation methods, steam condensation, etc., can solve the problems of unreachable emissions, single method, poor safety, etc., achieve clean tail gas emissions and solve air pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

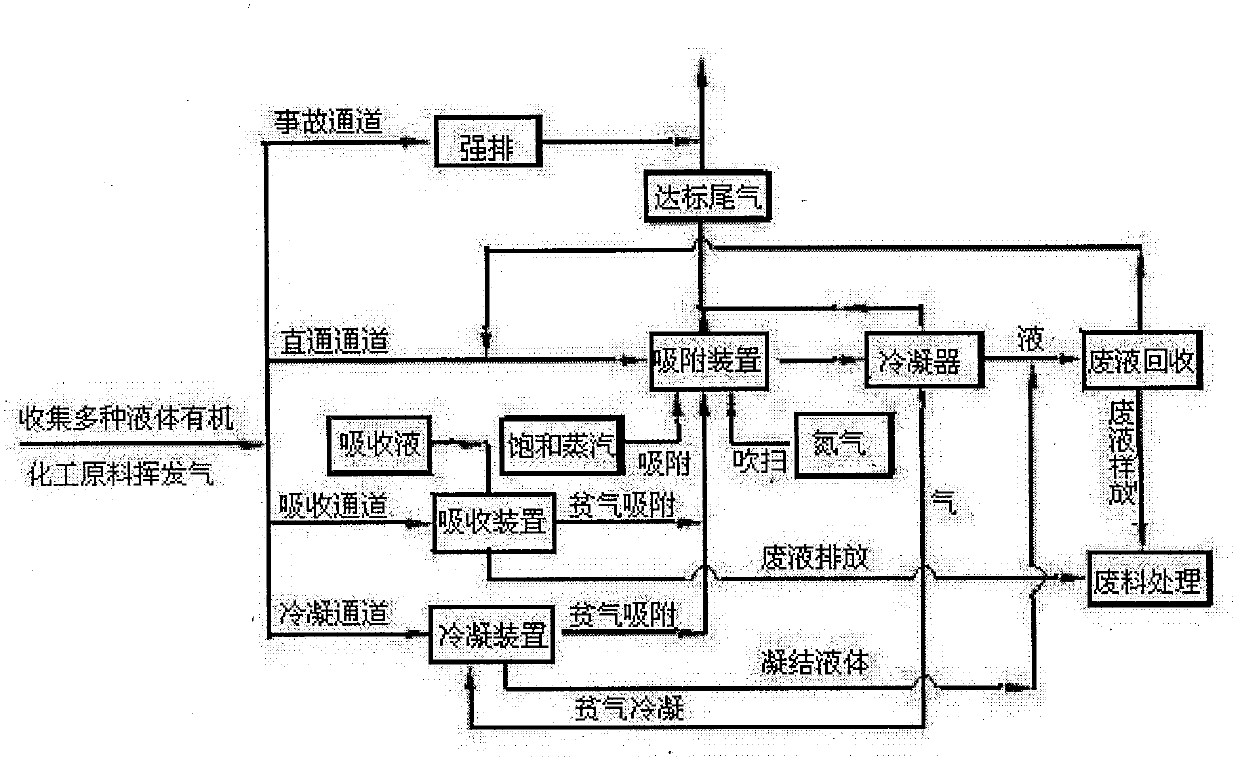

[0034] An intelligent centralized collection and treatment method for volatile gases of various liquid organic chemical raw materials, such as figure 1 The process flow shown includes:

[0035](1) Collect the volatilized gas of various liquid organic chemical raw materials in the petrochemical industry, such as the volatilized gas in a chemical industry area (a comprehensive chemical storage warehouse, or chemical storage dock, or comprehensive chemical plant) is concentrated in a waste gas collection and recycling station; this In the example, 28 kinds of chemical tail gas volatilized by materials are to be transported: furfural, propylene glycol, octanol, ethylene glycol, o-toluidine, tripropylene glycol, aniline, diesel oil, ethanol, acetone, butanone, acetic acid, isopropanol, methanol, acrylic acid , naphtha, gasoline, methyl tertiary, pure benz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com