Solenoid-drive liquid metallic rheostat

A liquid metal, electromagnetic drive technology, applied in the direction of liquid resistors, etc., can solve the problems of corrosion of the travel switch shell, poor contact of conductive contacts, increased operational complexity, etc., to achieve the effects of not easy electrochemical corrosion, low cost, and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

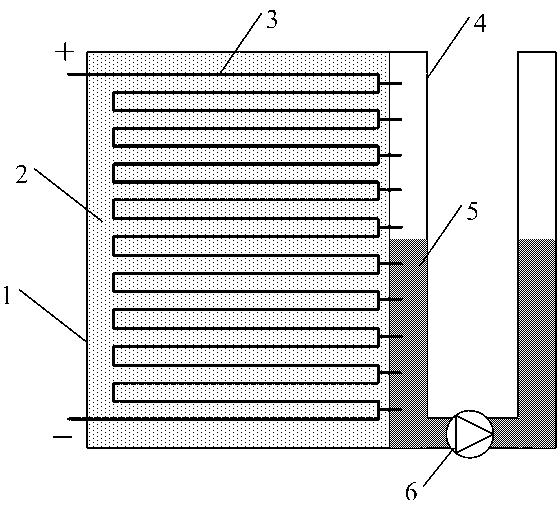

[0032] Embodiment 1 shows a typical application of the electromagnetically driven liquid metal varistor of the present invention. figure 1 Schematic diagram of the liquid metal varistor structure for electromagnetic actuation.

[0033] Such as figure 1 As shown, the electromagnetically driven liquid metal rheostat of this embodiment consists of a shell 1 , paraffin wax 2 , copper wire 3 , connector 4 , liquid metal 5 and electromagnetic pump 6 .

[0034] In this embodiment, the housing 1 is a cuboid with a size of 20cm×2cm×20cm, and the material is stainless steel.

[0035] Paraffin wax 2 fills the entire interior of the housing 1, and its melting point is 50°C.

[0036] The copper wire 3 has a diameter of 1 mm and a total length of 15 m, coiled into an S shape.

[0037] Connector 4 is made of polyethylene material and is U-shaped.

[0038] Liquid metal 5 is a gallium-indium-tin-zinc alloy (mass fraction: 61% Ga, 25% In, 13% Sn, 1% Zn), which is safe and non-toxic, with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com