Preparation method of rear-earth polishing powder

A rare earth polishing powder, rare earth technology, applied in rare earth metal compounds, chemical instruments and methods, polishing compositions containing abrasives, etc. Complex process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the rare earth carbonate, the mass ratio of each component is: the total amount of rare earth REO is 45%; the content of cerium oxide (CeO 2 / TREO) is 62%, and the lanthanum oxide content (La 2 o 3 / TREO) was 38%;

[0039] Mix the above 1000kg rare earth carbonate with 2000kg water, add 1kg sodium hydroxide, stir well, heat to 60°C, and age for 5h. Then add 90 kg of hydrofluoric acid with a weight concentration of 20%, continue to stir for 1 hour, and then centrifugally dehydrate to obtain rare earth fluorocarbonate;

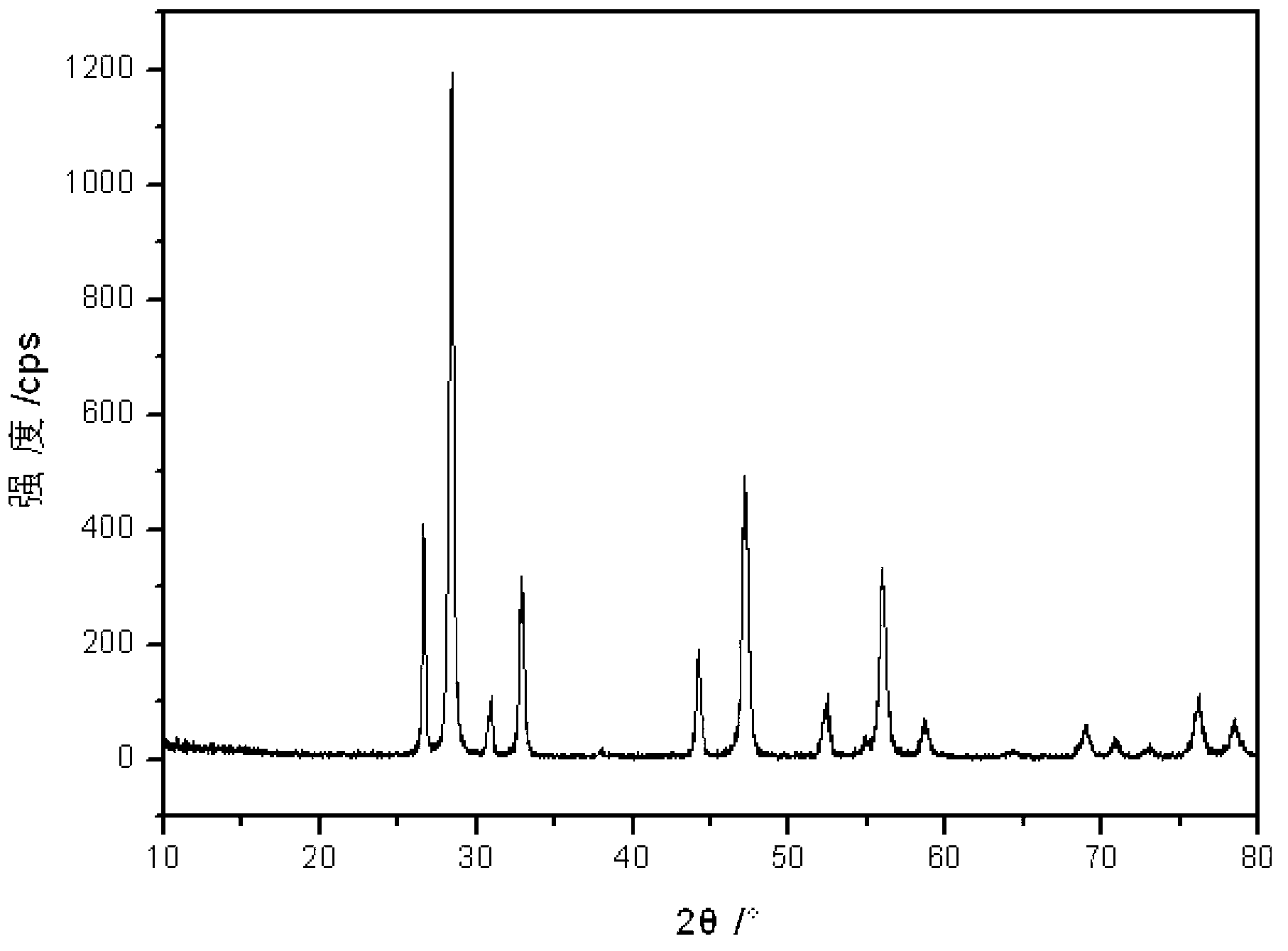

[0040] The rare earth fluorocarbonate is calcined at 940°C for 5 hours to obtain a precursor of rare earth oxyfluoride polishing powder, which is then subjected to jet crushing and jet classification to obtain the rare earth polishing powder. The polishing powder is tested by laser particle size analyzer: D 50 =1.01 μm. figure 1 It is the XRD of the obtained mixed rare earth polishing powder.

Embodiment 2

[0042] In the rare earth carbonate, the mass ratio of each component is:

[0043] The total amount of rare earth REO is 45%; the content of cerium oxide (CeO 2 / TREO) is 66%, and the lanthanum oxide content (La 2 o 3 / TREO) was 34%;

[0044] Mix the above 1000kg rare earth carbonate with 2000kg water, add 1.5kg sodium hydroxide, stir well, heat to 80°C, and age for 4h. Then slowly add 95 kg of 20% hydrofluoric acid, continue to stir for 2 hours, and centrifugally dehydrate to obtain rare earth fluorocarbonate;

[0045] The rare earth fluorocarbonate is calcined at 900°C for 6 hours to obtain the precursor of the rare earth oxyfluoride polishing powder, and then the rare earth polishing powder is obtained by jet crushing and jet classification. The polishing powder is tested by laser particle size analyzer: D 50 =1.8μm.

Embodiment 3

[0047] In the rare earth carbonate, the mass ratio of each component is:

[0048] The total amount of rare earth REO is 45%; cerium oxide (CeO 2 / TREO) is 62%, and the lanthanum oxide content (La 2 o 3 / TREO) is 32%, and the content of praseodymium oxide (Pr6 o 11 / TREO) is 6%;

[0049] Mix the above 1000kg rare earth carbonate with 1500kg water, add 2kg sodium hydroxide, stir well, heat to 90°C, and age for 3h. Then slowly add 105 kg of 20% hydrofluoric acid, continue to stir for 3 hours, and then centrifugally dehydrate to obtain rare earth fluorocarbonate;

[0050] Calcining the rare earth fluorocarbonate at 850° C. for 7 hours to obtain the precursor of the rare earth oxyfluoride polishing powder, and then crushing by air flow and classifying by jet flow to obtain the rare earth polishing powder. The polishing powder is tested by laser particle size analyzer: D 50 =1.2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com