Blackbody material and energy-saving radiation cup made of such blackbody material

A black body and cup bottom technology, applied in lighting and heating equipment, furnace components, furnaces, etc., can solve the problems of high price, high manufacturing cost, destroy the blackness of black body materials, etc., achieve high thermal melting point and increase the bonding area. , the effect of increasing the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A blackbody material:

[0025] A black body material, characterized in that the black body material is composed of the following substances in weight percentage: 95% silicon carbide, 0.5% ferrous oxide, 0.5% manganese dioxide and 4% aluminum oxide.

Embodiment 2

[0026] Example 2: An energy-saving radiant cup:

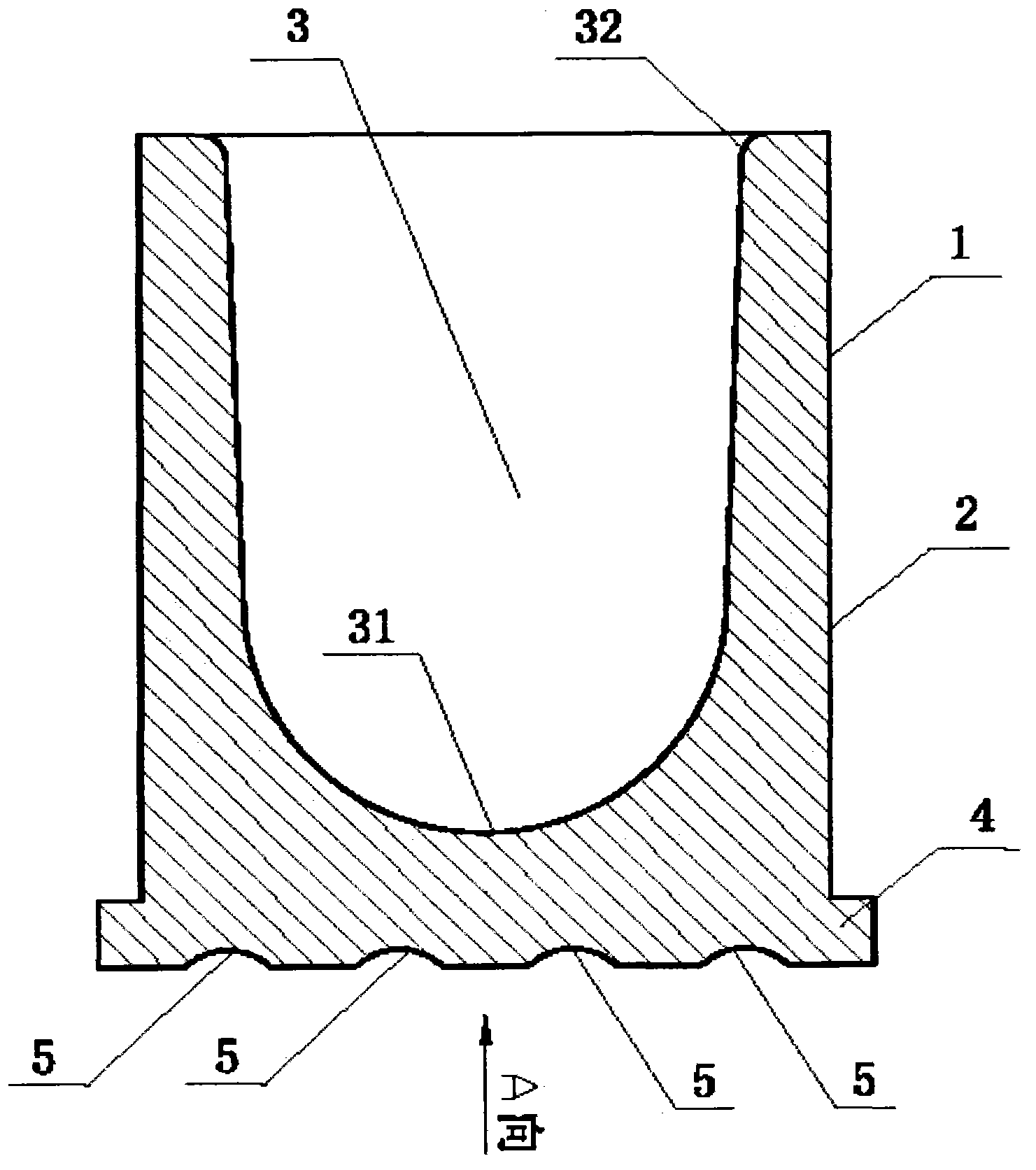

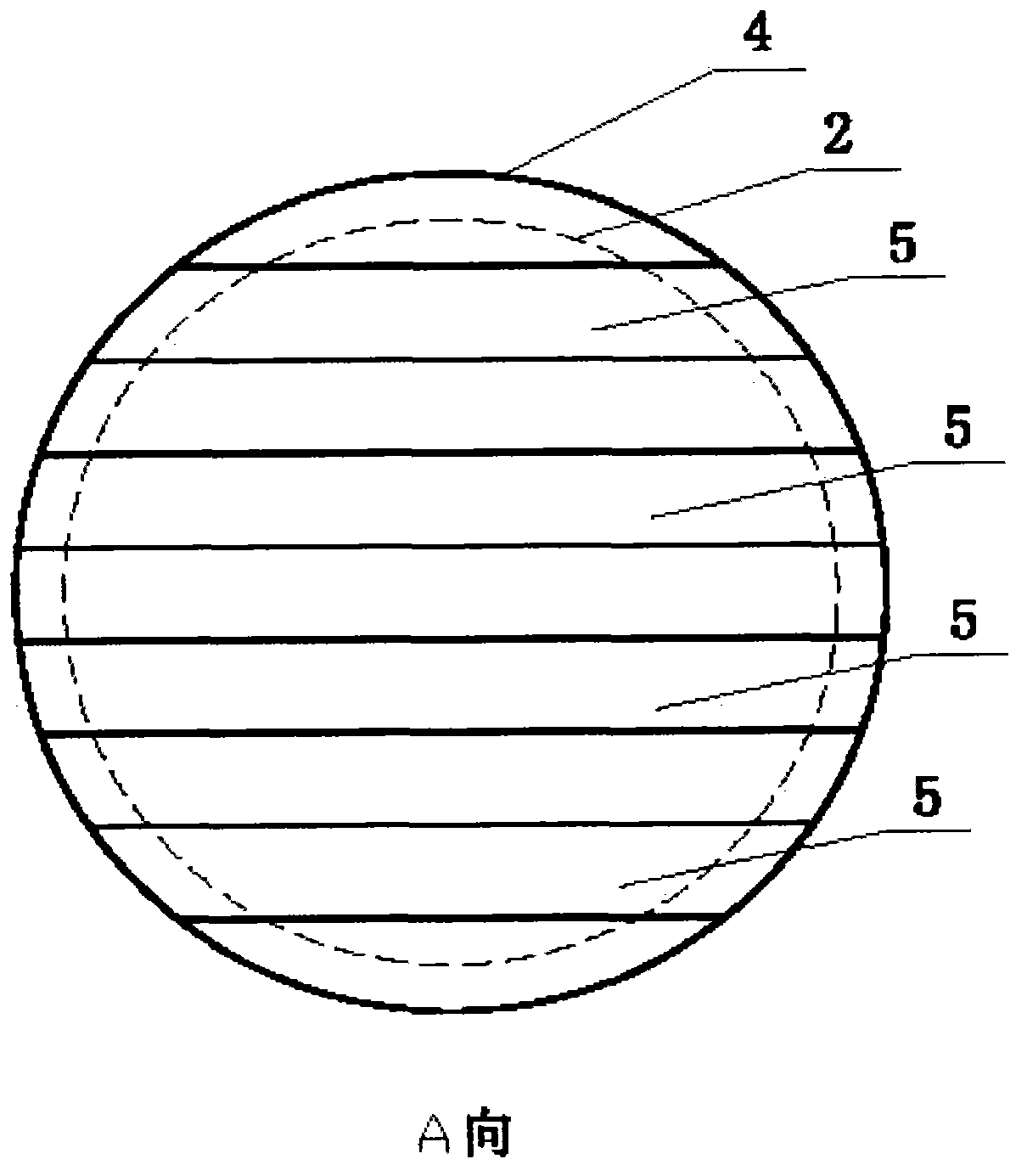

[0027] Such as figure 1 and 2 Shown is an energy-saving radiant cup 1 made of blackbody material, the energy-saving radiant cup 1 is made of the blackbody material described in Embodiment 1, the energy-saving radiant cup 1 includes a cup body 2 and a cup bottom 4, the The cup body 2 is straight cylindrical, the middle of the cup body 2 is a cavity 3, the bottom 31 of the cavity 3 is spherical, the section of the cavity outlet 32 is trapezoidal, and the angle between the two sides of the cavity trapezoidal outlet is 4°; the diameter of the cup bottom 4 is larger than that of the cup body 2, and four arc-shaped grooves 5 are arranged in parallel on the cup bottom 4 plane.

[0028] When in use, many radiant cup components are bonded into the industrial kiln, using its blackness and increasing the radiation area in the industrial kiln, strengthening the heat transfer in the furnace, increasing production, reducing energy cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com