Novel synthesis method of glycidyl amine epoxy resin

A technology of glycidyl amines and epoxy resins, which is applied in the direction of organic chemistry, can solve the problems of many reaction side reactions and high chlorine content in products, and achieve the effects of low chlorine content, high yield and purity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

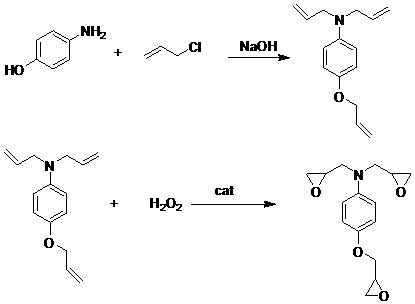

[0023] Example 1 Synthetic process of triglycidyl p-aminophenol (DGGAP).

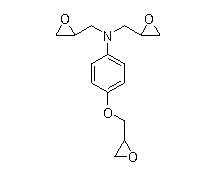

[0024] Triglycidyl p-aminophenol, also known as p-aminophenol epoxy resin or triglycidyl p-aminophenol, is an epoxy resin containing p-aminophenol structure. Reddish-brown liquid, viscosity (Pa·s) 1.30-2.30, epoxy value 106-115, cured product tensile strength 65.7MPa, flexural strength 142.2MPa, heat distortion temperature 202°C, volume resistivity 3×1016Ω·cm. It is prepared by reacting p-aminophenol with epichlorohydrin. Mainly used as glass cloth laminates, glass fiber winding products, aerospace equipment, sports equipment, casting products of micro-motor parts, sealing, high temperature resistant adhesives, etc. Its structural formula is as follows:

[0025]

[0026] Triglycidyl p-aminophenol (DGGAP) adopts the following process route: p-aminophenol and propylene chloride are used to obtain intermediates under the action of alkali; intermediates and hydrogen peroxide undergo epoxidation reacti...

Embodiment 2

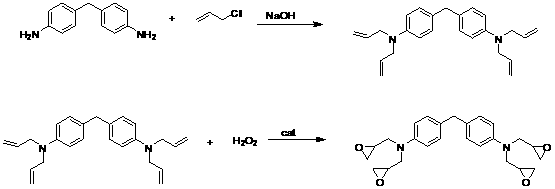

[0032] Example 2 N,N,N,N,-tetraepoxypropyl-4,4-diaminodiphenylmethane

[0033] N,N,N,N,-tetraepoxypropyl-4,4-diaminodiphenylmethane (TGDN) is a yellow or brown viscous liquid, which is a high-performance matrix resin for composite materials. This type of glycidylamine resin is characterized by good wettability to glass fiber and carbon fiber, and the cured product has good heat resistance and nuclear radiation resistance, so it is mainly used in aerospace and military industries, such as rocket auxiliary engines. Winding molding shell, etc. The presence of phenyl structural units in its structure and its high epoxy functional group lead to high cross-linking density after curing of the resin. Its structural formula is as follows:

[0034]

[0035] TGDN was first developed by Swiss CIBA-GETGY company, its company brand is AralditeMY720, and the domestic similar product brand is AG-80.

[0036] N,N,N,N,-tetraepoxypropyl-4,4-diaminodiphenylmethane (TGDN) adopts the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com