Preparation method of carboxymethyl chitin

A technology of carboxymethyl chitin and chitin, applied in the field of material science, can solve the problems of large environmental pollution and serious molecular weight degradation of products, and achieve the effects of environmental friendliness, high degree of substitution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 0.25g chitin to 49.75g NaOH and CO(NH 2 ) 2 In the mixed solution, the mass percentage of NaOH is 6%, CO(NH 2 ) 2 The mass percentage of chitin is 2%, and it is frozen at -18°C for 24 hours, thawed at room temperature, and fully stirred to prepare a chitin solution with a mass percentage concentration of 0.5%. According to the molar ratio of chitin monomer and sodium chloroacetate as 1:4, add 0.574g sodium chloroacetate to the chitin solution, and stir at 0°C for 72 hours, adjust the pH value of the chitin solution to Neutral, dialyze the neutral chitin solution in distilled water for 7 days until the sodium chloride is completely removed, and dry the dialyzed liquid by freeze-drying to obtain spongy carboxymethyl chitin.

Embodiment 2

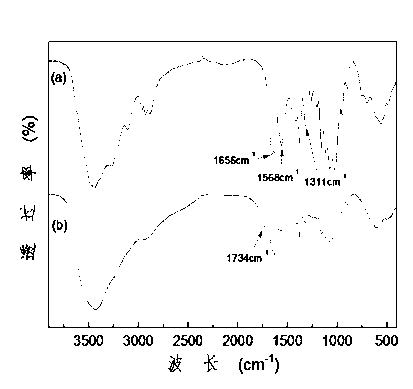

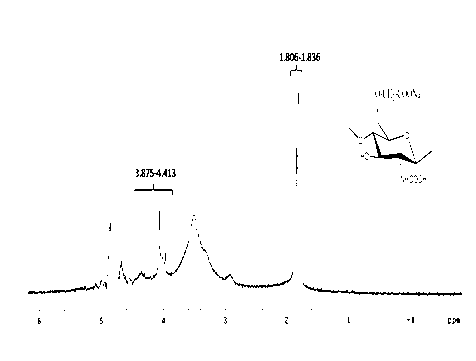

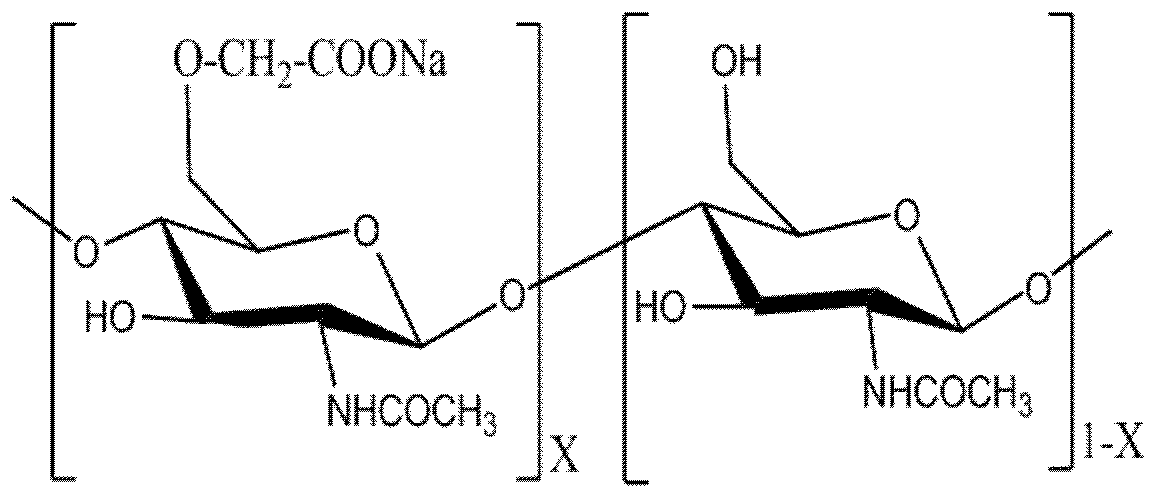

[0028] Add 1g of chitin to 49g of NaOH and CO(NH 2 ) 2 In the mixed solution, the mass percentage of NaOH is 8%, CO(NH 2 ) 2 The mass percentage of chitin is 4%, and it is frozen at -22°C for 18 hours, thawed at room temperature, and fully stirred to prepare a chitin solution with a mass percentage concentration of 2%. According to the molar ratio of chitin monomer to sodium chloroacetate as 1:7, add 4.017g sodium chloroacetate to the chitin solution, and stir at 15°C for 72 hours, adjust the pH value of the chitin solution to Neutral, dialyze the neutral chitin solution in distilled water for 7 days until the sodium chloride is completely removed, and dry the dialyzed liquid by freeze-drying to obtain spongy carboxymethyl chitin. figure 1 In (b) curve and figure 2 They are the infrared spectrogram and nuclear magnetic resonance spectrogram of carboxymethyl chitin obtained in this example respectively.

[0029] from figure 1 It can be seen from the curve (a) that the ch...

Embodiment 3

[0032] Add 1g of chitin to 49g of NaOH and CO(NH 2 ) 2 In the mixed solution, the mass percentage of NaOH is 8%, CO(NH 2 ) 2 The mass percentage of chitin is 4%, and it is frozen at -22°C for 18 hours, thawed at room temperature, and fully stirred to prepare a chitin solution with a mass percentage concentration of 2%. According to the molar ratio of chitin monomer and sodium chloroacetate as 1:10, add 5.739g sodium chloroacetate to the chitin solution, and stir at 15°C for 72 hours, adjust the pH value of the chitin solution to Neutral, dialyze the neutral chitin solution in distilled water for 7 days until the sodium chloride is completely removed, and dry the dialyzed liquid by freeze-drying to obtain spongy carboxymethyl chitin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com