Light-curing hydrophilic lubricating coating as well as preparation method and using method thereof

A lubricating coating and light-curing technology, applied in coatings and other directions, can solve the problems of reduced coating drying time, large heat and time consumption, and achieve the effect of improving adhesion and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Synthesis of photoactive hydrophilic resin:

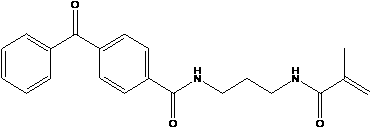

[0045] Weigh 5.55g (50mmol) of vinylpyrrolidone into a three-neck flask, then add N-[3-(4-benzoylbenzamido)propyl]methacrylic acid dissolved in 10ml of dimethyl sulfoxide Amide 0.18g (0.52mmol), put nitrogen into the flask to remove the air, add azobisisobutyronitrile 0.1g (0.6mmol), tetramethylethylenediamine 0.006ml (0.042mmol), the liquid surface is filled with nitrogen Finally, close the container and heat at 55 degrees Celsius for 12 hours. After the reaction, the solution was precipitated with ether, and the precipitate was filtered out and dried in an oven to obtain 5 g of a white solid. The detected photoactive group benzophenones is 1.1 mmol / g.

Embodiment 2

[0046] Embodiment 2 Preparation and application method of photocurable hydrophilic lubricating coating:

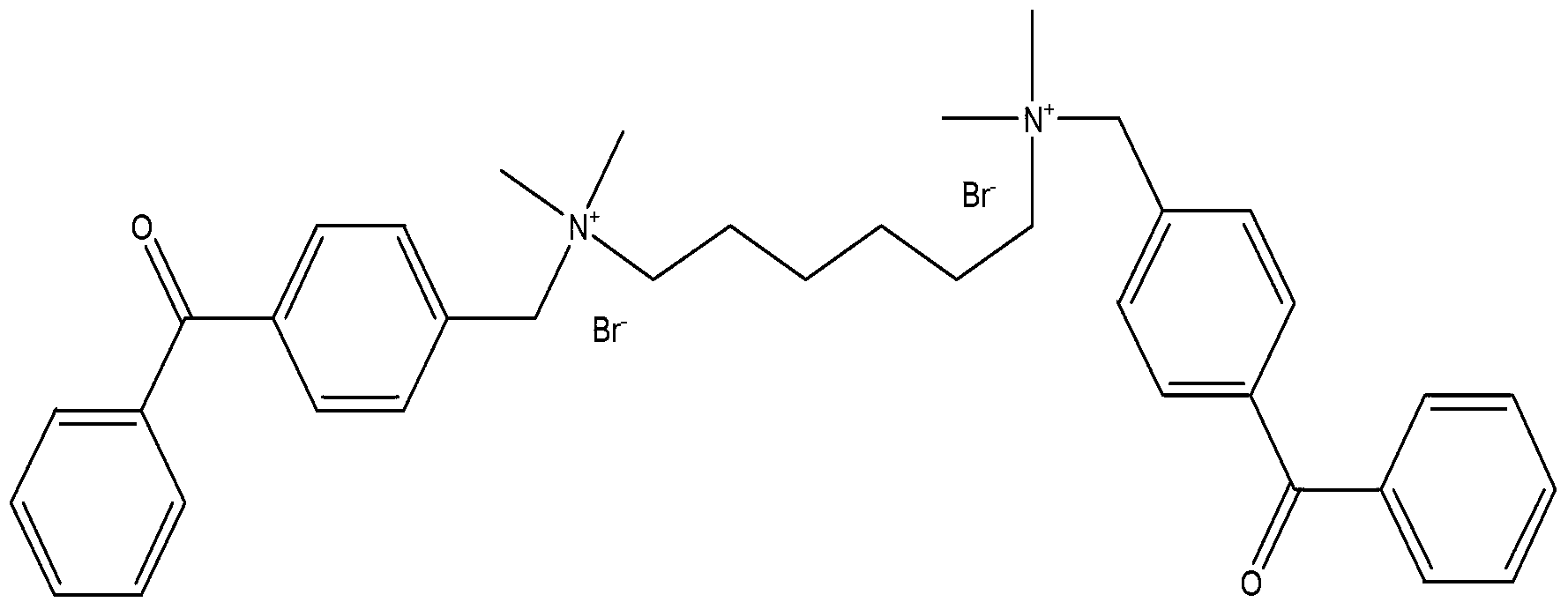

[0047] The resin in Example 1, and the cross-linking agent ethylene bromide bis(4-benzoylbenzyl dimethyl ammonium salt) weight ratio is 5 / 0.2 total 5.2g solids were added to 30ml isopropanol and 20ml In pure water, a coating solution is formed after ultrasonic dissolution. Immerse the pre-cleaned and dried polyurethane substrate in the coating solution for 1-2 minutes, take it out, and let it dry at room temperature. After the substrate coated with the coating solution was cured for 2 minutes after UV irradiation, the UV intensity was 1mw / cm 2 .

[0048] After testing, the coating has good lubricity and strong adhesion after being wetted with water.

Embodiment 3

[0049] Embodiment 3 Preparation and application method of photocurable hydrophilic lubricating coating:

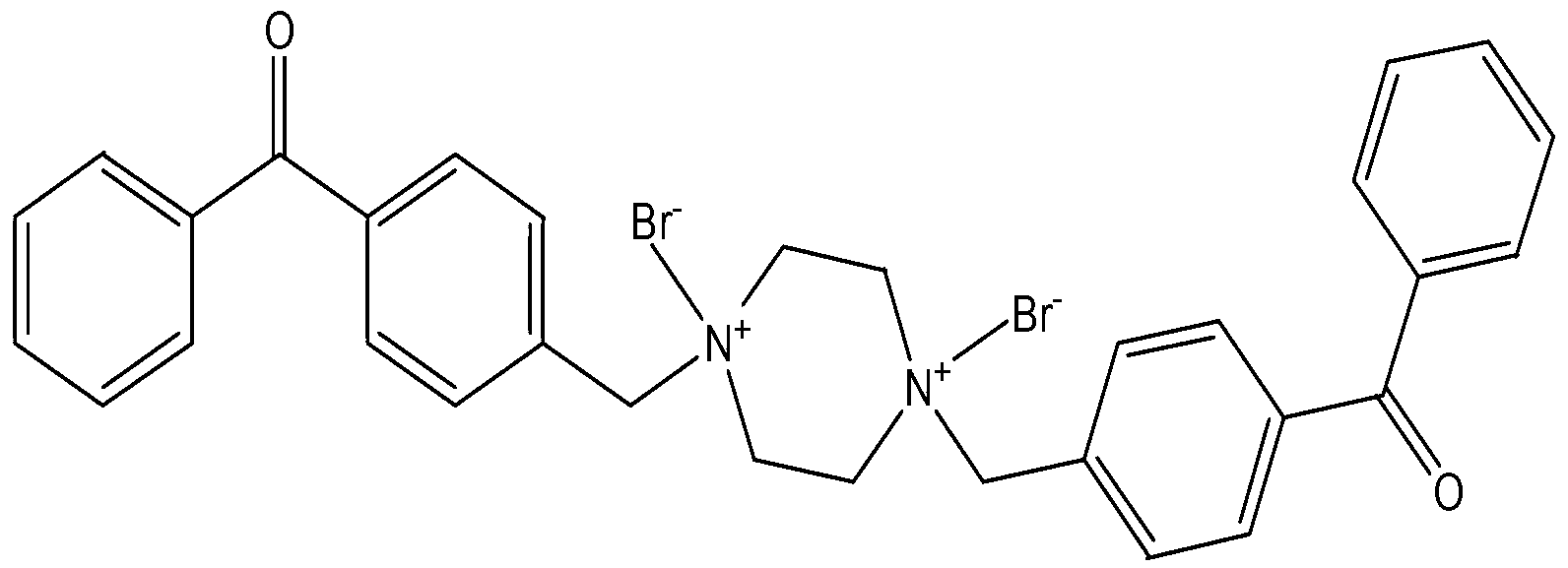

[0050]Resin in embodiment 1, and cross-linking agent hexamethylene bromide bis(4-benzoyl benzyl dimethyl ammonium salt) weight ratio is the solid of 6 / 0.25 altogether 6.25g joins 30ml Virahol and 20ml of pure water, dissolved by ultrasonic to form a coating solution. Immerse the pre-washed and dried polyurethane substrate in the coating solution for 1-2 minutes, take it out, and let it dry at room temperature. After curing the substrate coated with the coating solution for 2.5 minutes after UV irradiation, the UV light intensity was 1mw / cm 2 .

[0051] After testing, the coating has good lubricity and strong adhesion after being wetted with water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com