Thermosetting adhesive composition, and heat resistant adhesive film and wiring film using the same

An adhesive and thermosetting technology, applied in the field of thermosetting adhesive compositions, heat-resistant adhesive films and wiring films, to achieve excellent low-temperature adhesiveness, not easy to curl, moisture-resistant reliability and long-term heat-resistant reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

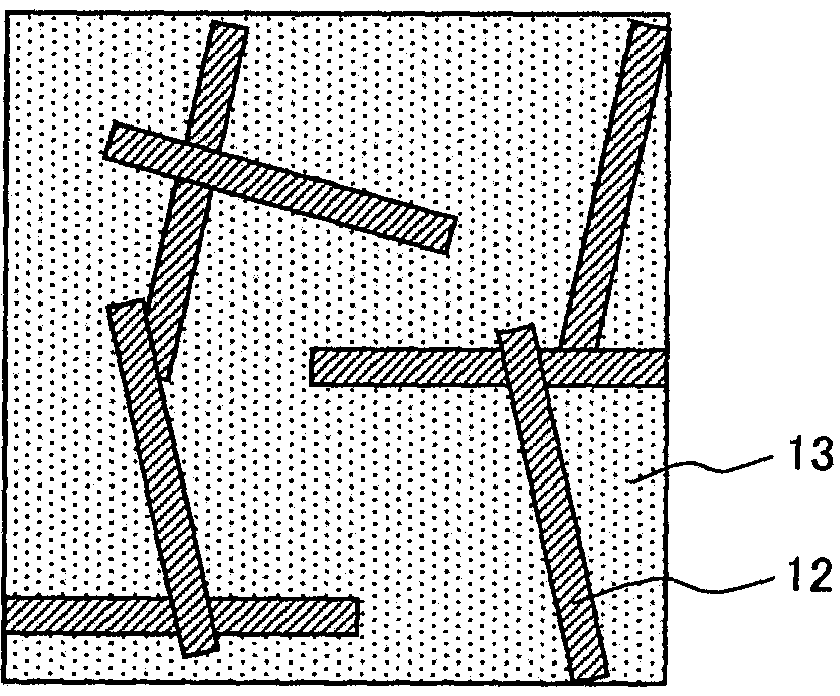

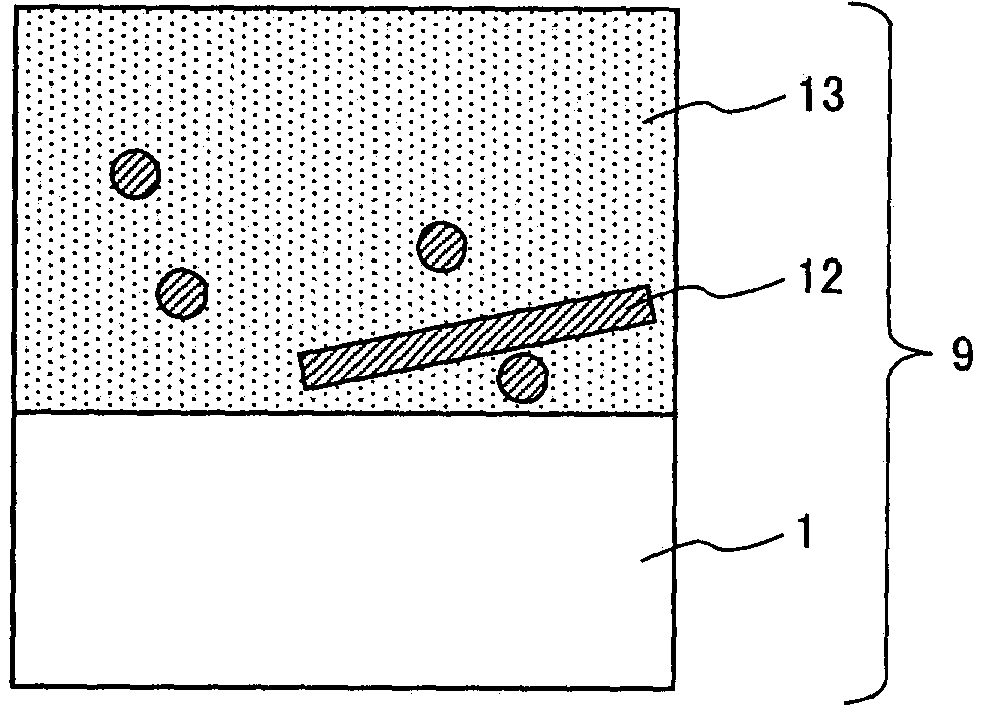

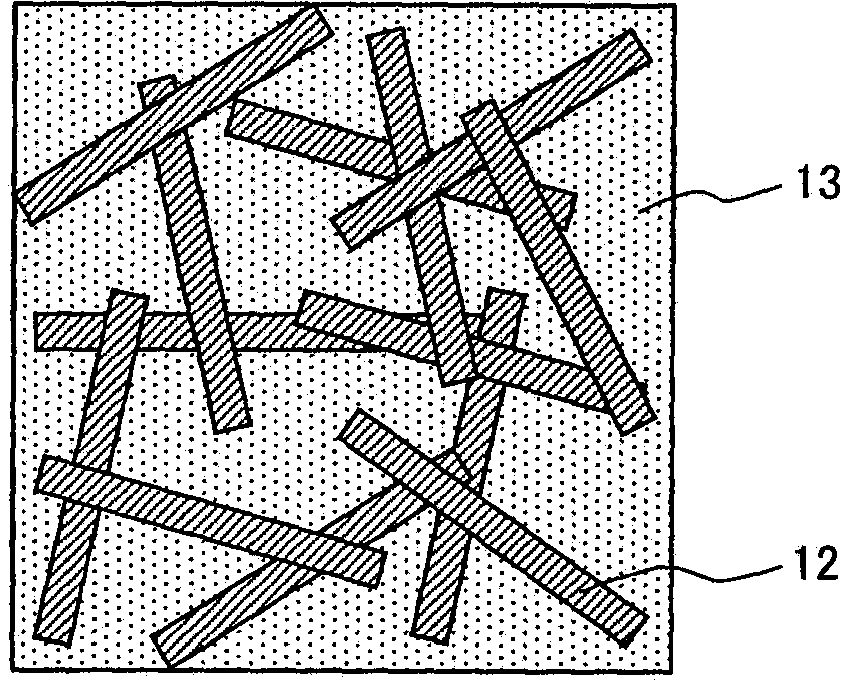

[0176] Table 3 shows the thermosetting adhesive compositions of Examples 1-6. Examples 1 to 6 are examples of thermosetting adhesive compositions containing inorganic acicular fillers. Table 4 shows the characteristics of the heat-resistant adhesive film produced by applying the thermosetting adhesive composition on the polyimide film and drying it, and the laminated film obtained by heat-sealing the heat-resistant adhesive film and copper foil.

[0177] In the heat-resistant adhesive films of Examples 1 to 6, generation of strong curl was suppressed, and slight warpage of 4 to 10 mm was observed. The addition of inorganic acicular fillers effectively suppresses strong curling. Even after the humidity resistance test, the adhesive strength is 1.0 to 1.3 kN / m, and the soldering heat resistance at 280°C and storage stability are also good.

[0178] From the above, the following results were obtained: the heat-resistant adhesive film composed of the thermosetting adhesive compo...

Embodiment 7、8

[0188] Examples 7 and 8 are examples of thermosetting adhesive compositions having different blending amounts of inorganic acicular fillers. In the heat-resistant adhesive film of this example, strong curling was suppressed, and only slight warping of 4 to 9 mm was observed. The adhesive strength is 0.9 to 1.2 kN / m even after the humidity resistance test, and the 280°C soldering heat resistance and storage stability are also good. In Examples 7 and 8, the wiring embedding property was the same as that of Comparative Examples 1 to 5 which did not contain the inorganic acicular filler, and showed excellent values.

[0189] From the above, the following results were obtained: the heat-resistant adhesive films of Examples 7 and 8 were less likely to curl and had excellent storage stability, and the laminated film and wiring film using the same had excellent adhesiveness, moisture resistance, and soldering heat resistance.

[0190] Next, the thermosetting adhesive compositions of ...

Embodiment 9、10

[0196] Examples 9 and 10 are examples of thermosetting adhesive compositions having different compounding amounts of non-reactive plasticizers. The heat-resistant adhesive film of this example suppressed the occurrence of strong curling, and only slight warpage of 7 mm or more and 10 mm or less was observed. Even after the humidity resistance test, the adhesive strength is not less than 0.8 kN / m and not more than 1.0 kN / m, and the 280° C. soldering heat resistance and storage stability are also good. In addition, good wiring embedding properties were obtained even at a pressure of 3 MPa.

[0197] From the above, the following results were obtained: the heat-resistant adhesive film composed of the thermosetting adhesive composition of Examples 9 and 10 and the polyimide film is not easy to curl and has excellent storage stability, and the laminated film and wiring film using it , Excellent in adhesion, moisture resistance and soldering heat resistance.

[0198] Next, the ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com