A method and device for multiple irradiation laser quenching

A technology of laser quenching and multiple irradiation, applied in the field of laser surface strengthening treatment, can solve the problems of low production efficiency and shallow depth of hardened layer, and achieve the effects of improving production efficiency, preventing melting and improving depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

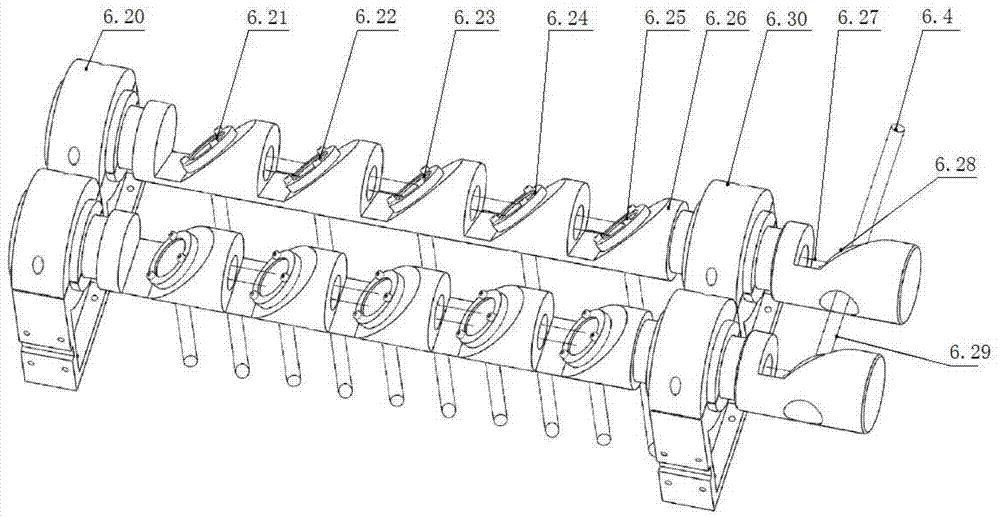

[0119] Example 1: The application of the laser quenching process of selective multiple irradiation in the laser quenching of automobile molds.

[0120] In this embodiment, semiconductor lasers are used to perform selective array laser quenching on automobile molds made of 50CrMnMo materials, and four laser beams are output from four laser beams. The power of each laser beam is 1500W, and the spot size of the four laser beams on the workpiece is Φ7mm. , and arranged in a 1×4 array with a pitch of 3.5 mm, the size and array of processing units are the same as the array of input laser beam spots. t 1 is 0.008s, t 2 is 0.004s, the number of irradiations is 131, the quenching cycle is 1.57s, and the relative moving speed is 960mm / min. Quenching depth 1.0mm.

[0121] The conventional laser quenching method uses a single beam to perform single continuous laser quenching on a single processing unit. The laser power is 1200W, the spot diameter is Φ7mm, the quenching time is 1.0s, an...

Embodiment 2

[0123] Embodiment 2: The application of the selected area multiple irradiation flight laser quenching process in the laser quenching of the guide rail of the machine tool.

[0124] In order to solve the problem of low efficiency of laser quenching for discrete hardening patterns, the present invention proposes a selective-area multiple-irradiation flight laser quenching method, which specifically includes three forms, namely: the workpiece is fixed and the laser processing head moves. Irradiation laser quenching method; flying multiple irradiation laser quenching method with fixed laser processing head and moving workpiece; flying multiple irradiation laser quenching method with mutual movement of workpiece and laser processing head.

[0125] The surface of the long metal part of the 40Cr machine tool guide rail is subjected to discrete selective area array multiple irradiation flying laser quenching, the power of the fiber laser is 6000W, and a beam of laser output from the la...

Embodiment 3

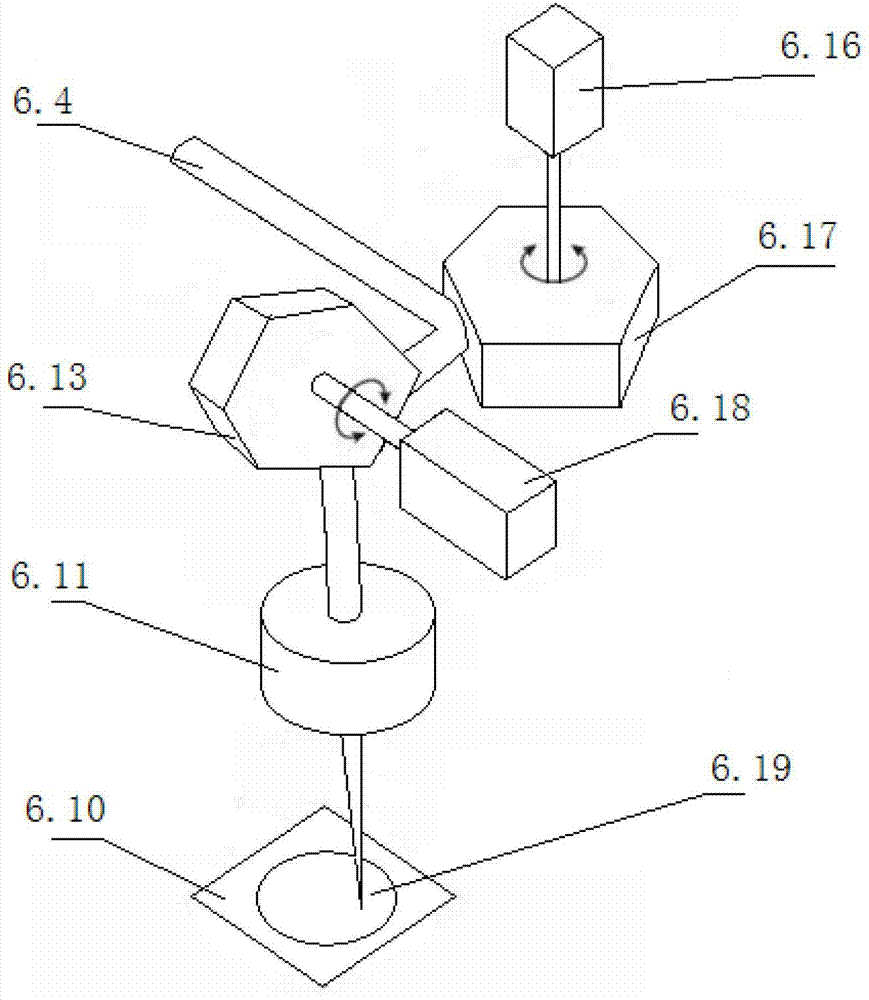

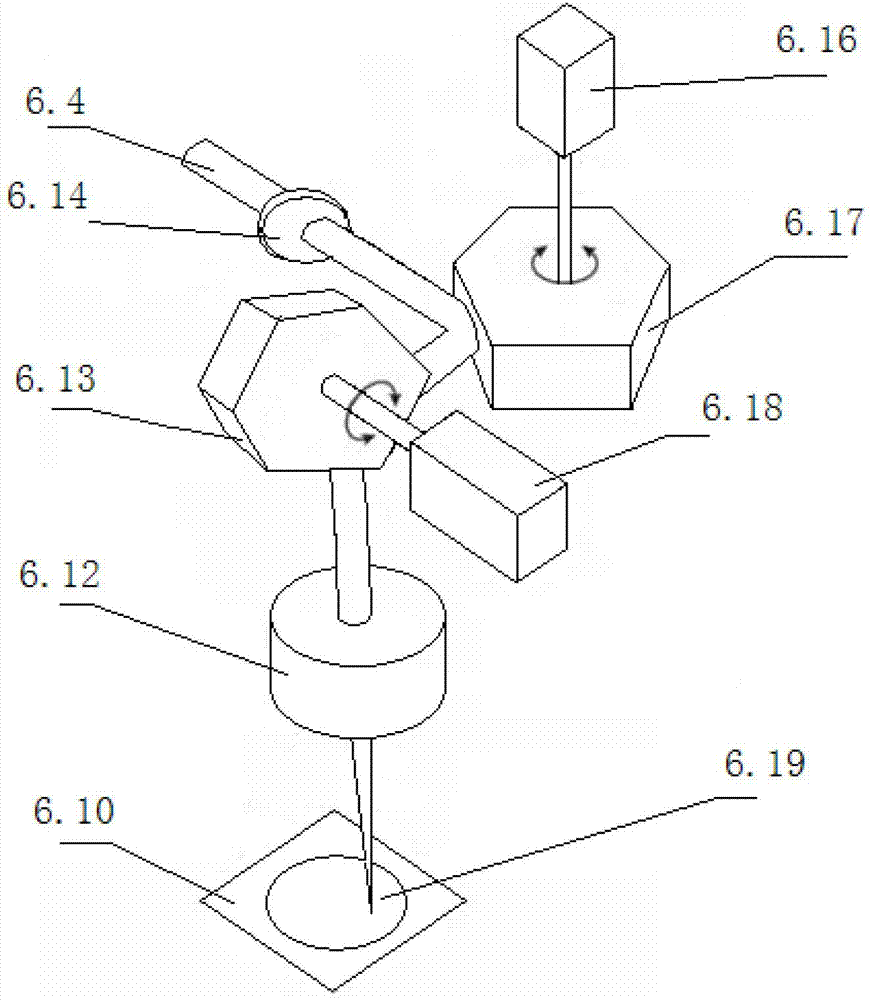

[0128] Example 3: Application of multiple irradiation laser quenching process in large mold

[0129] This example uses 10.6 μm CO 2 The laser quenches the large mold made of 50CrNiMo material, the spot size is Φ7mm, the laser power is 6000W, the processing unit size obtained through the rotating mirror is 7mm×35mm, the scanning speed of the laser in the processing unit is 500mm / s, and the number of irradiation times is 17 times, t 1 0.07s, t 2 is 0.09s, the quenching cycle T time is 2.72s, the relative moving speed is 350mm / min, the vector direction of the relative moving speed is perpendicular to the length direction of the processing unit, a single pass quenching can obtain a 35mm wide quenching area, and the overlapping amount is 2mm. Before laser quenching, special SiO is sprayed on the surface of the workpiece 2 Light-absorbing paint, after the light-absorbing paint on the surface of the workpiece is dry, the subsequent laser quenching is carried out. Through the mirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com