Preparation method of medical cartilage support material

A scaffold material and cartilage technology, which is applied in the field of preparation of medical cartilage scaffold materials, can solve the problems of cytotoxicity, residual toxic substances, and cannot be completely removed, and achieves the effect of simplifying the process flow and reducing process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

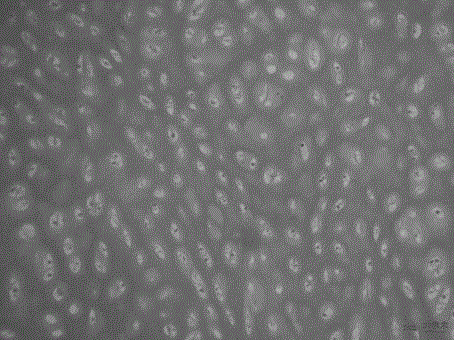

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of medical cartilage scaffold material

[0029] (1) Pretreatment separation and initial washing of cartilage tissue

[0030] The costal cartilage tissue of freshly slaughtered pigs was cleaned, the periosteum was removed, cut into strips with a thickness of 0.5-4 cm, and washed 3 times with water for injection.

[0031] (2) Virus inactivation

[0032]Adopt low-concentration peracetic acid-ethanol solution method to inactivate virus, this step is carried out in the constant temperature ultrasonic cleaning device that cleaning tank can vibrate, and wherein the volume percentage composition of peracetic acid is 0.05~0.2% (preferably 0.1%), The inactivation time is 1-2h (preferably 1h), the temperature range is 4-40°C, and then washed 2-5 times in phosphate buffered saline, each time for 15min, and the pH value of the washed phosphate buffered saline is detected, When the pH reaches 6.5-7.5, wash the material with flowing water for injection, and...

Embodiment 2

[0041] Embodiment 2: the physical performance, chemical performance, histology and biological performance detection of the medical cartilage scaffold material prepared in embodiment 1

[0042] 1. Physical performance testing

[0043] 1) Mechanical performance testing

[0044] Preparation of the materials provided in Example 1, the materials prepared by Courtman's four-step method and the natural porcine costal cartilage tissue without decellularization, each group of materials took 3 samples, soaked in phosphate buffer saline for 30 minutes, and used The multi-functional mechanical measuring instrument detects the compressive modulus, and calculates the compressive modulus according to the formula. Compression modulus=ΔP / A×L / ΔL (ΔP represents the pressure difference between two points in the linear segment of the pressure-displacement curve, A represents the area of the material under test, L represents the thickness of the material, and ΔL represents the displacement betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com