Environmental-friendly material used for imitation porcelain tableware and preparing method thereof

A technology for environmentally friendly materials and tableware, which is applied to table utensils, applications, home utensils, etc., can solve the problems of low heat resistance and strength performance, environmental impact, non-biodegradable tableware, etc. The effect of improving the thermal stability of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

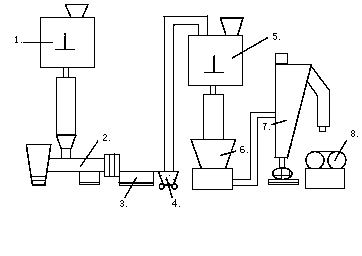

Image

Examples

Embodiment Construction

[0023] An environmentally friendly material for melamine tableware and a preparation method thereof, the recipes of Embodiments 1-5 are shown in Table 1, and the specific steps are as follows:

[0024] (1) Prepare the following raw materials according to mass percentage: 65-85% of cereal protein plastics, 0.5-5% of heat stabilizers, 10-30% of reinforcing agents and 0.5-2% of crosslinking agents. The protein content is greater than 85%, and the cereal protein plastic is rice protein plastic, wheat protein plastic or corn protein plastic; the heat stabilizer is at least one of epoxidized soybean oil, vitamin C or vitamin E; the enhancer is biological At least one of the calcium-based materials, the biological calcium carbonate is oyster shell powder with a particle size of 325-1250 mesh; the biological cross-linking agent is at least one of genipin or tannic acid;

[0025] (2) Add cereal protein plastics, heat stabilizers and enhancers to mixer 1 and heat to 80-120°C, mix evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com