Synchronous flue gas desulfurization and denitrification process and system for coal-fired power plant

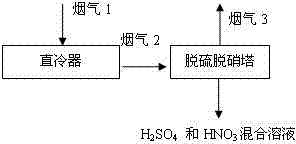

A technology for desulfurization, denitrification, and coal-fired power plants, which is applied in the intersection of energy engineering and environmental engineering, and can solve the problems of high operation cost, complicated operation and maintenance, and large construction investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

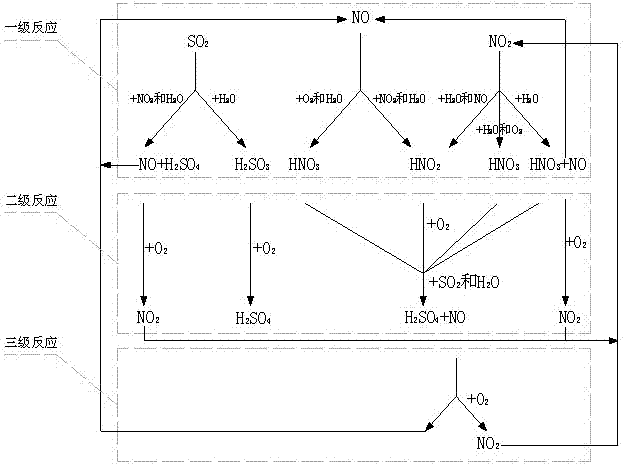

Method used

Image

Examples

Embodiment approach

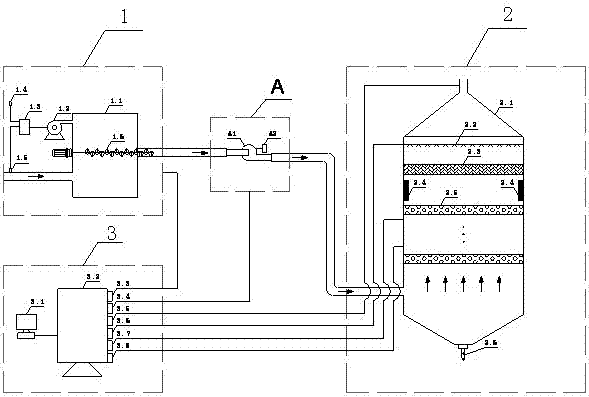

[0104] According to the process requirement, the specific embodiment of the present invention is as follows figure 2 shown. The entire design process starts from the desulfurization and denitrification tower according to the reverse engineering method, and finally reaches the direct cooler. Each specific design unit also adopts the reverse engineering method, such as desulfurization and denitrification tower starting from the design of high-speed wire mesh eliminator. Design tools that can be used include large-scale commercial computational fluid dynamics software CFD (Computation Fluid Dynamics), plant design management system software PDMS (Plant Design Management System), etc., and required measuring instruments include specific surface meters, flue gas analyzers, ion chromatographs Wait.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com