Preparation method of UHMWPE (Ultrahigh Molecular Weight Polyethylene) hollow fiber membrane

A fiber membrane and hollow technology, which is applied in the field of preparation of filtration membranes for water treatment, can solve the problems of membrane filament performance attenuation, pollution resistance, no hydrophilicity, etc., and achieves saving raw material costs, prolonging service life, and pollution resistance. lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

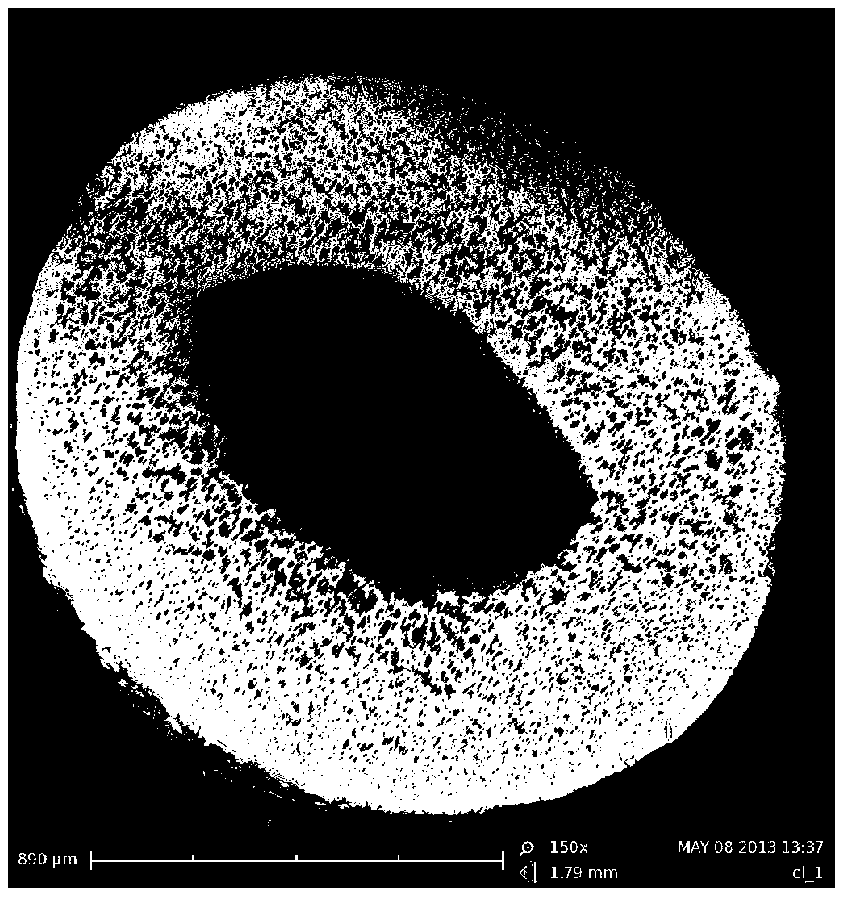

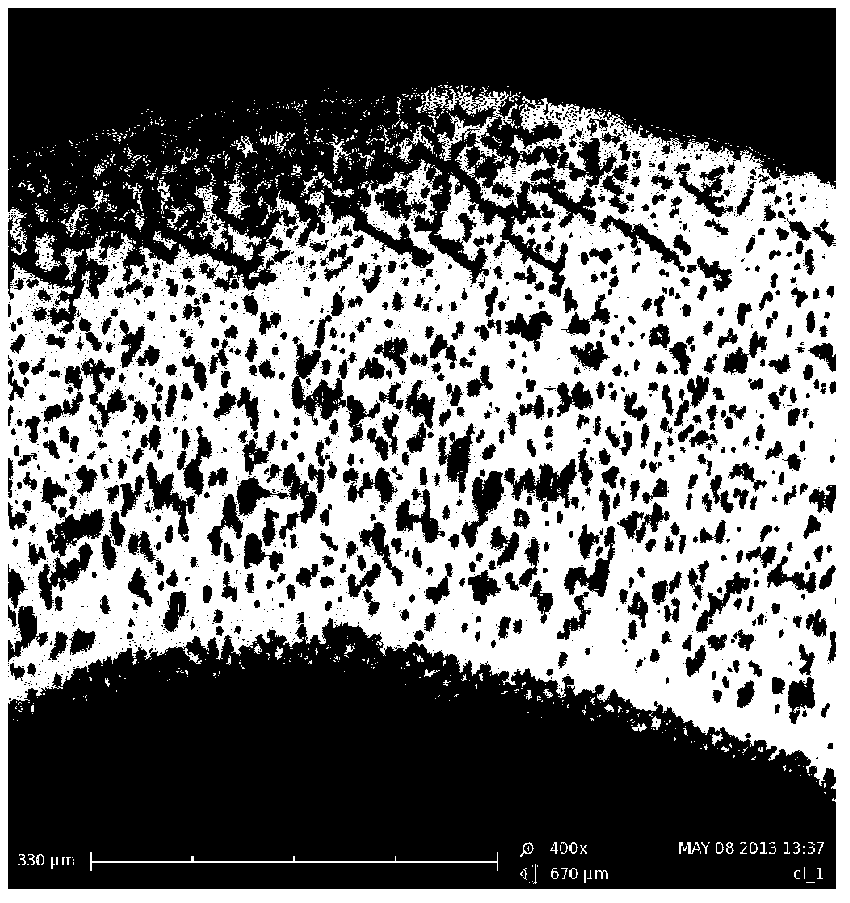

[0039] Ultra-high molecular weight polyethylene, select the ultra-high molecular weight polyethylene product of BASF, the model is BS015, the weight average molecular weight is 1500000, the content is 22.5%, the weight average molecular weight of PE-PEO copolymer is 4000, the content is 5%, antioxidant 1076 is 0.5%, and the diluent is white oil. It is mixed and melted in a twin-screw extruder at 200-250°C. The homogeneous polymer melt is metered by a gear pump, extruded from a double-tube spinneret, and passed through Cooling, winding, extraction, stretching, and setting to obtain a hollow fiber membrane, and the flow rate of oil-free and water-free air forming the inner cavity of the fiber is 6ml / min. The stretching temperature is 80°C, the stretching ratio is 1.5 times, and the cooling bath is water at 35°C. The setting temperature is 120°C, and the setting time is 30 minutes. The obtained hollow fiber membrane has an inner and outer diameter of 0.8 / 1.6 mm, a cross-sectiona...

Embodiment 2

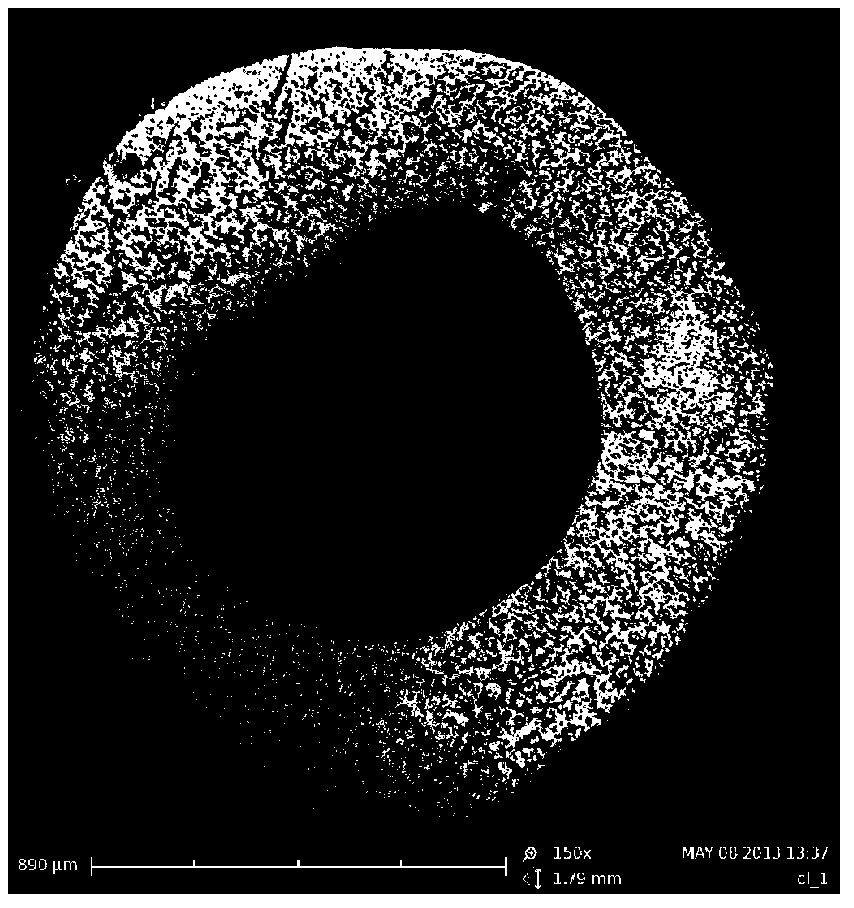

[0041] Ultra-high molecular weight polyethylene with a weight-average molecular weight of 1,800,000 and a content of 20.0%, an ethylene-vinyl alcohol copolymer (EVOH) with a weight-average molecular weight of 6,000 and a content of 7%, an antioxidant 1010 of 0.5%, and a diluent of white oil. It is mixed and melted in a twin-screw extruder at 200-250°C. After being metered by a gear pump, the polymer homogeneous melt is extruded from a double-tube spinneret, cooled, coiled, extracted, and then stretched. , stereotyped to obtain a hollow fiber membrane, and the flow rate of oil-free and water-free air forming the inner cavity of the fiber is 6ml / min. The stretching temperature is 90°C, the stretching ratio is 2.0 times, and the cooling bath is water at 35°C. The setting temperature is 120°C, and the setting time is 30 minutes. The inner and outer diameters of the obtained hollow fiber membranes are 0.9 / 1.8mm, the cross-sectional pore structure of the membrane is a sponge-like p...

Embodiment 3

[0043] Ultra-high molecular weight polyethylene, the weight average molecular weight is 1500000, the content is 22.5%, the weight average molecular weight of PE-PEO copolymer is 5000, the content is 5%, the antioxidant 1076 is 0.5%, the diluent is white oil, and it is extruded in twin-screw It is mixed and melted at 200-250°C in the discharge machine. After being metered by a gear pump, the homogeneous polymer melt is extruded from a double-tube spinneret, cooled, wound, extracted, and then stretched and shaped to obtain a hollow Fiber membrane, oil-free and water-free air flow rate of 6ml / min forming the inner cavity of the fiber. The stretching temperature is 80°C, the stretching ratio is 1.5 times, and the cooling bath is water at 35°C. The setting temperature is 120°C, and the setting time is 30 minutes. The inner and outer diameters of the obtained hollow fiber membranes are 0.8 / 1.6mm, the cross-sectional pore structure of the membrane is a sponge-like pore structure, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com